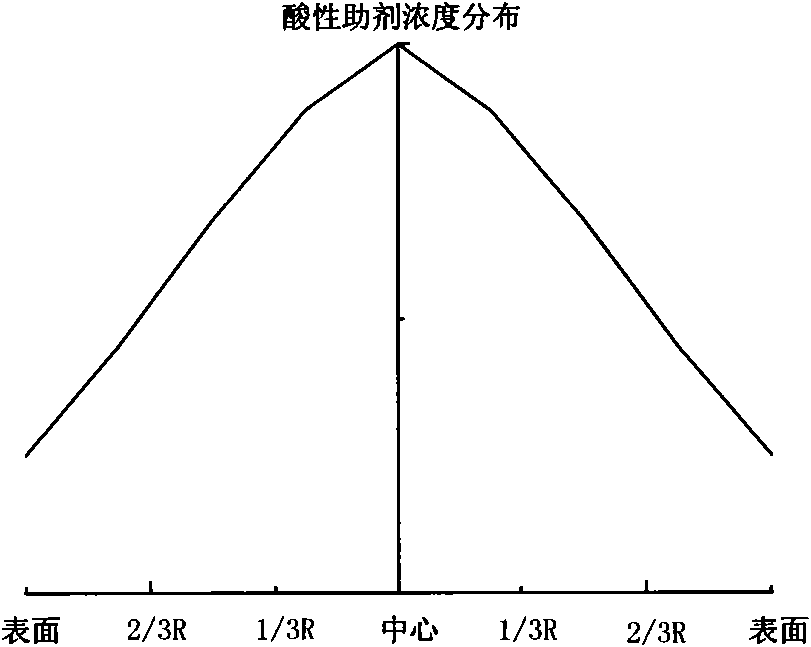

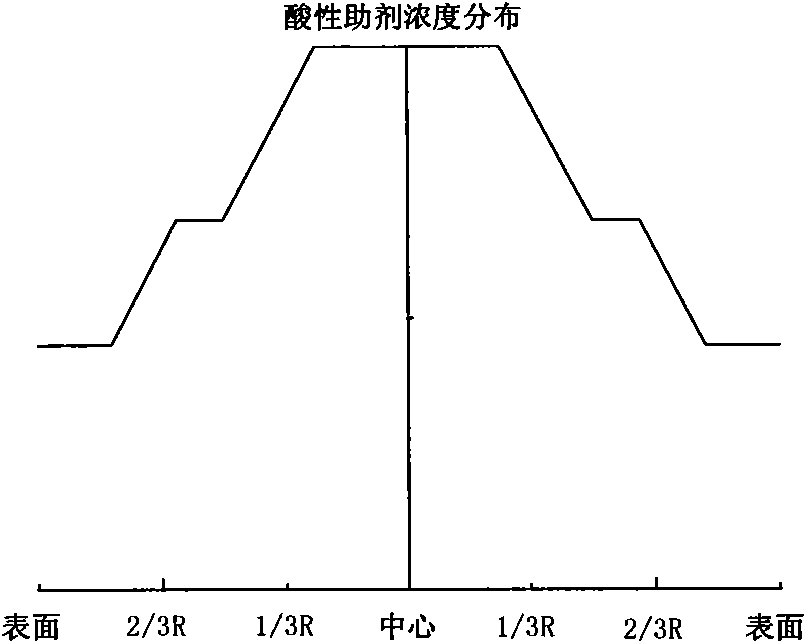

Hydrogenation catalyst carrier the concentrations of acid additives of which are distributed in gradient reducing and preparation method thereof,

A technology of hydrogenation catalyst and acid auxiliary agent is applied in the directions of catalyst carrier, catalyst activation/preparation, chemical instrument and method, etc., to achieve the effects of simple operation, broad application prospect and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

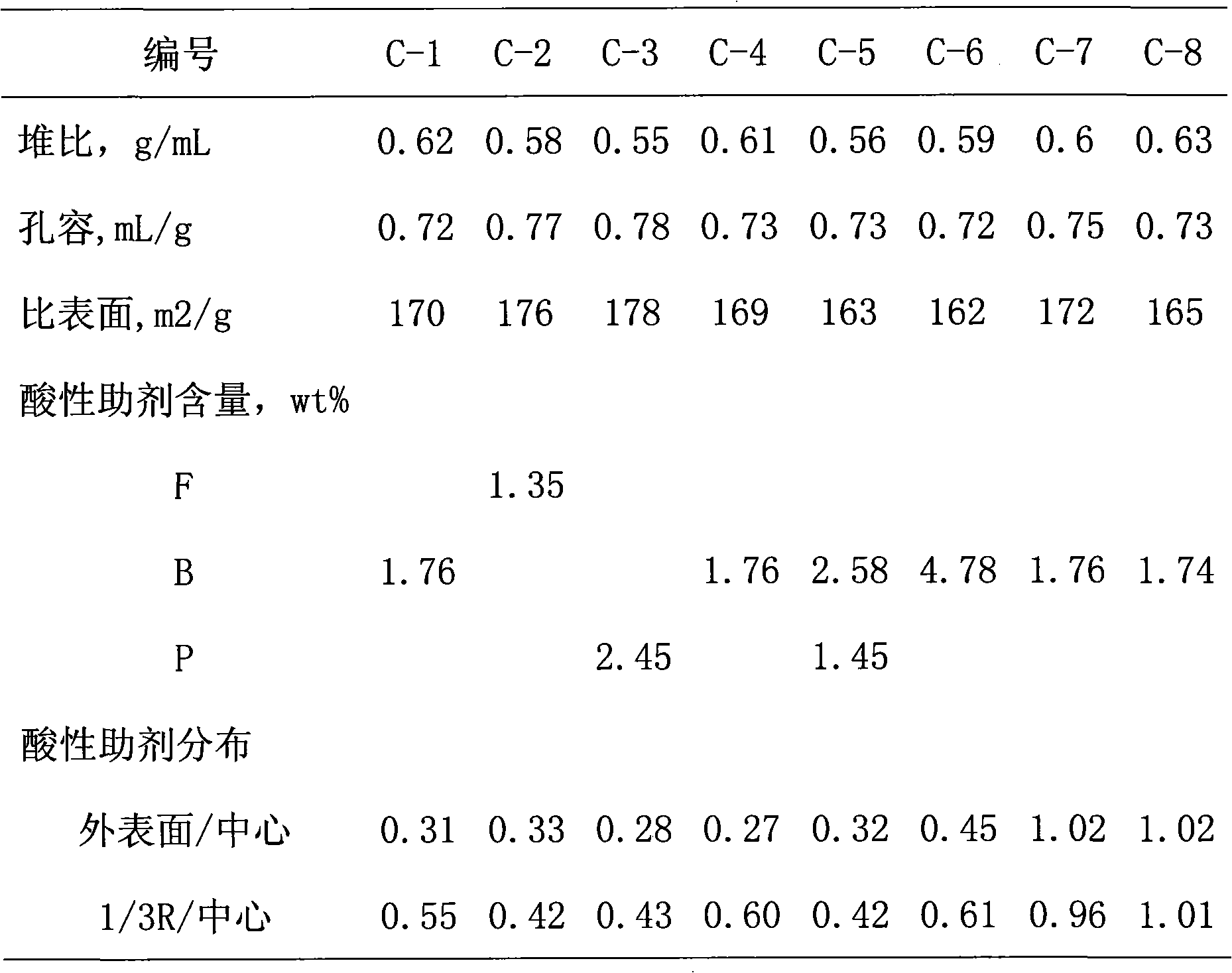

Embodiment 1

[0024] In this example, Al 2 o 3 As a carrier, the water absorption rate is 1.10mL / g, and the catalyst carrier with a gradient distribution of the acidic additive concentration is prepared by a saturated spray immersion method.

[0025] Weigh 150g carrier, spray and dip 82.5mL aqueous solution containing 10.0g 85% phosphoric acid (Beijing Chemical Reagent Company, the same below), drop 82.5mL deionized water into the dipping solution at a constant speed during the spray dipping process, and spray while dripping Soak, spray and soak for 5 minutes. After being homogenized for 10 minutes in a spray-dipping device, it was dried at 60°C for 2 hours, then dried at 120°C for 5 hours, and then calcined at 500°C for 3 hours in air to obtain a catalyst carrier. Numbered C-1.

Embodiment 2

[0027] This example uses 1.5m% SiO 2 Al 2 o 3 As a carrier, the water absorption rate is 1.10mL / g, and a catalyst carrier with a gradient distribution of acidic additives is prepared by a saturated spray immersion method.

[0028] Weigh 150g carrier, spray immerse in 60mL aqueous solution containing 4g 50% ammonium fluoride, after spray immersion, spray immerse in 105mL aqueous solution containing 2.0g 50% ammonium fluoride (Beijing Chemical Reagent Company, the same below), spray immerse in 15 minutes Finish. After being homogenized for 10 minutes in a spray-dipping device, it was dried at 120° C. for 4 hours, and then calcined in air at 500° C. for 3 hours to obtain a catalyst carrier. Numbered C-2.

Embodiment 3

[0030] In this example, 1.0m% SiO 2 and 1.5m%TiO 2 Al 2 o 3 As a carrier, the water absorption rate is 1.10mL / g, and a catalyst carrier with a gradient distribution of acidic additives is prepared by a saturated spray immersion method.

[0031] Weigh 150g carrier, spray 50mL aqueous solution containing 25.0g 85% boric acid (Beijing Chemical Reagent Company, the same below), drop 115mL deionized water at a constant speed during the spray immersion process, and stir in the immersion solution, while dripping Spray and soak while entering, and soak in 5 minutes. After being homogenized for 10 minutes in the spray-dipping equipment, it was dried at 60°C for 2 hours, taken out and dried at 120°C for 5 hours, and then calcined in air at 500°C for 3 hours to obtain a catalyst carrier. Numbered C-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com