Treatment method for improving selectivity of catalytic cracking catalyst

A treatment method, catalytic cracking technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., to achieve improved selectivity, reduced dry gas yield and coke yield, and uniform activity and selectivity distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

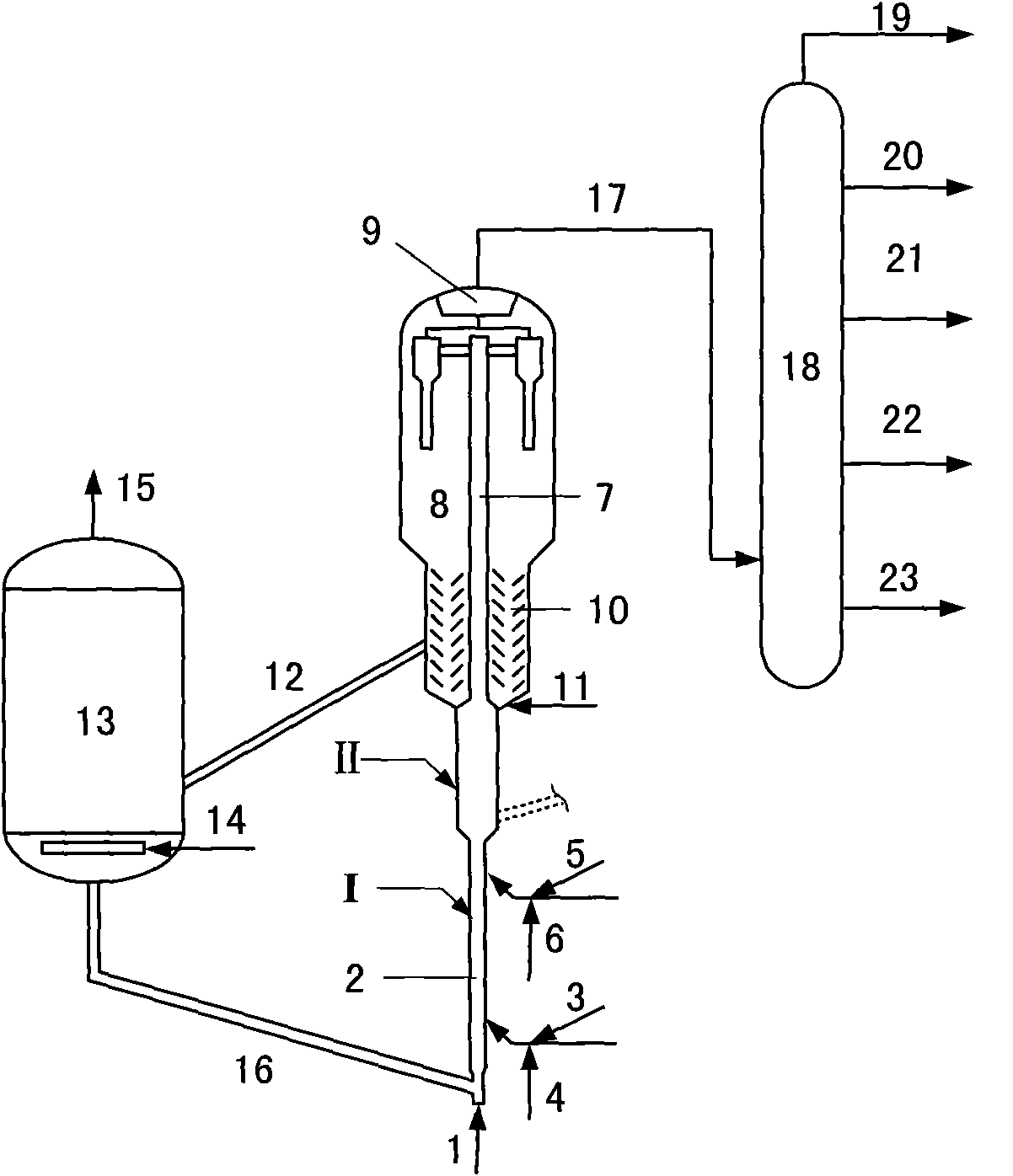

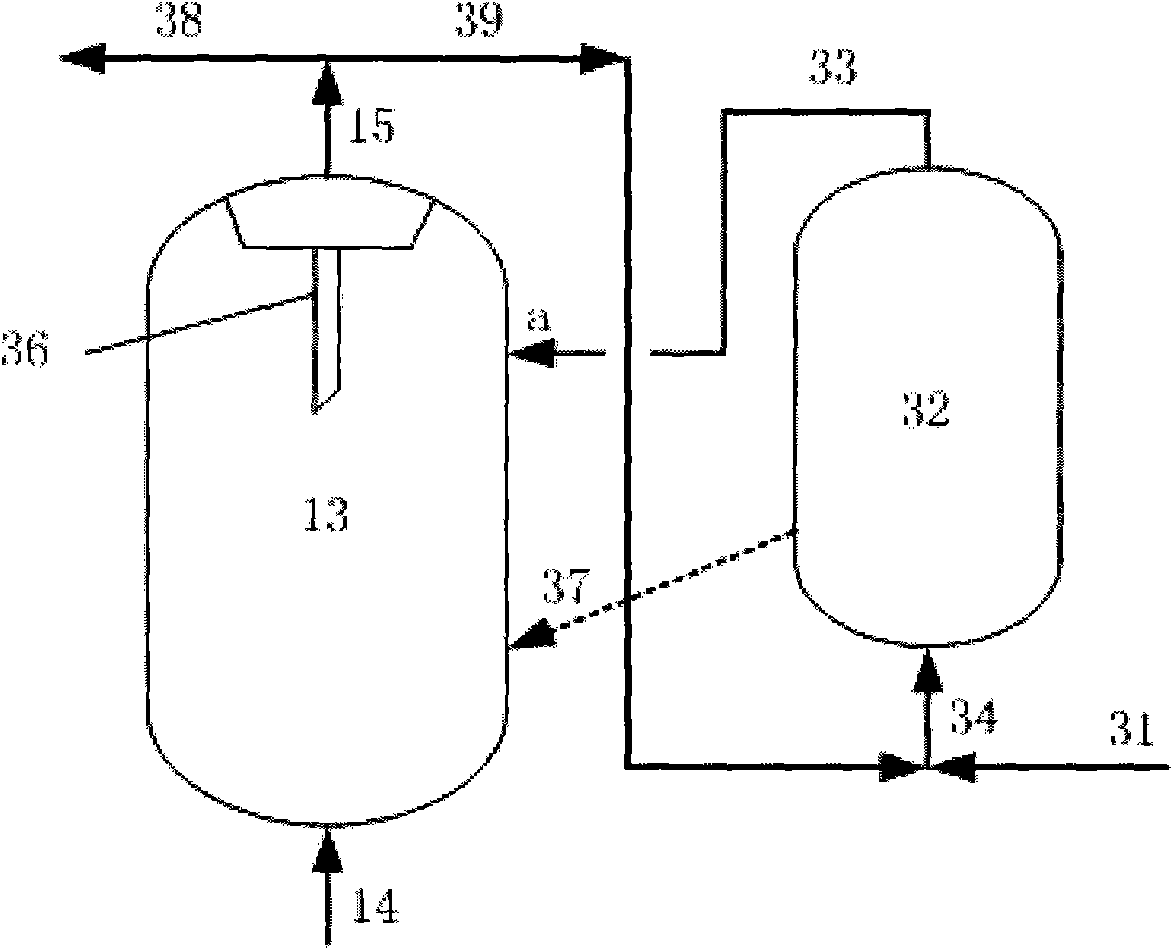

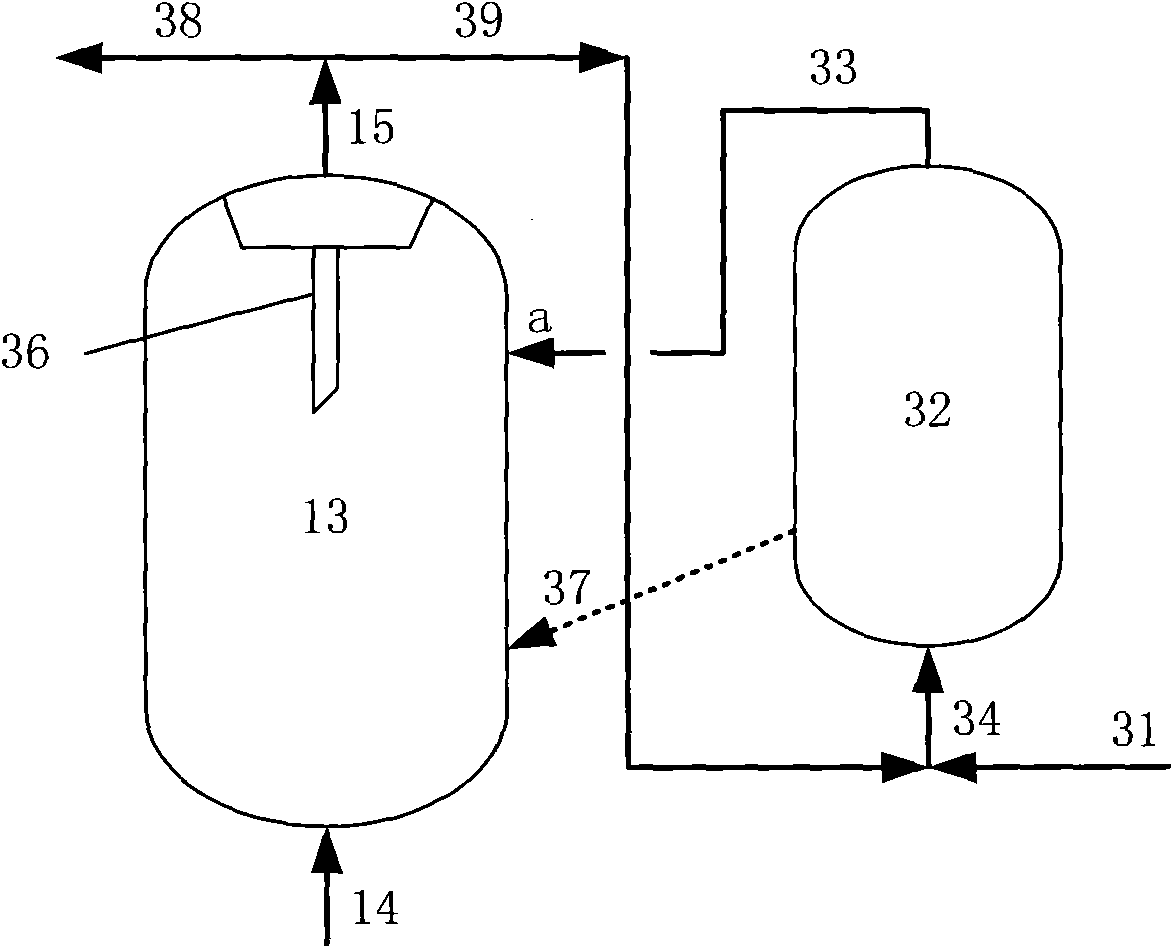

[0027] This example follows figure 1 and 2 The process of the fresh catalyst MLC-500 was tested at 600 °C, the aging medium (including water vapor and regeneration flue gas, the weight ratio of water vapor, regeneration flue gas and aging medium was 0.5), and the apparent linear velocity was 0.3 m / s , Aging time of 40 hours and then added to the regenerator, with the vacuum residue feed oil A as the raw material for catalytic cracking, the test was carried out on the medium-sized device of the riser reactor, the inferior raw material entered the bottom of the riser reactor, and was mixed with the catalyst MLC -500 contact and catalytic cracking reaction occurs, in the reaction zone I, the reaction temperature is 600°C, and the weight hourly space velocity is 100h -1 , the weight ratio of catalyst to raw material is 6, and the weight ratio of steam to raw material is 0.05; in reaction zone II, the reaction temperature is 500°C and the weight hourly space velocity is 30h -1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com