Method for controlling rolling mode of pinch pass mill set

A control method and leveling technology, applied in the field of cold rolling, can solve the problems of unstable rolling, low roughness copy rate, and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

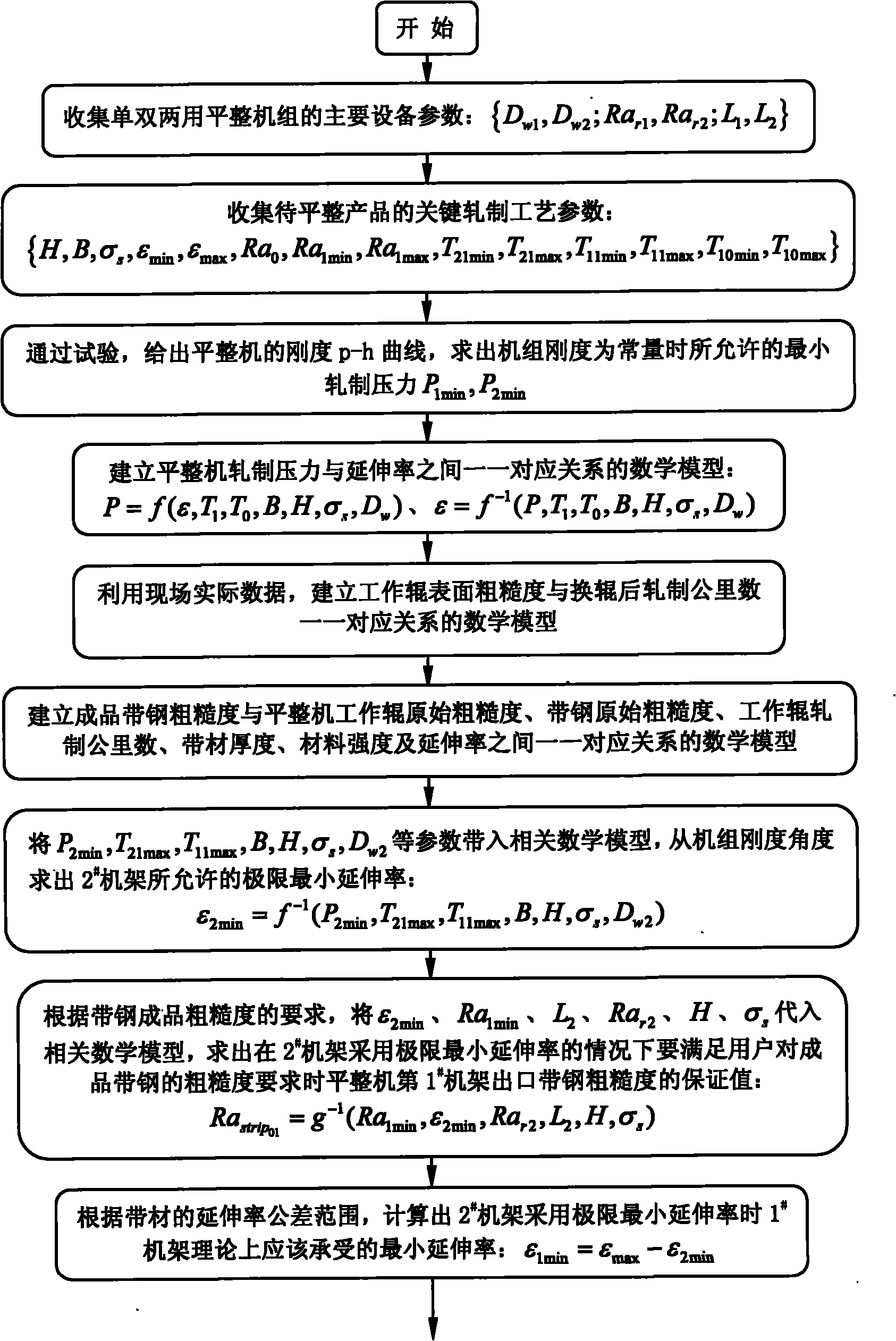

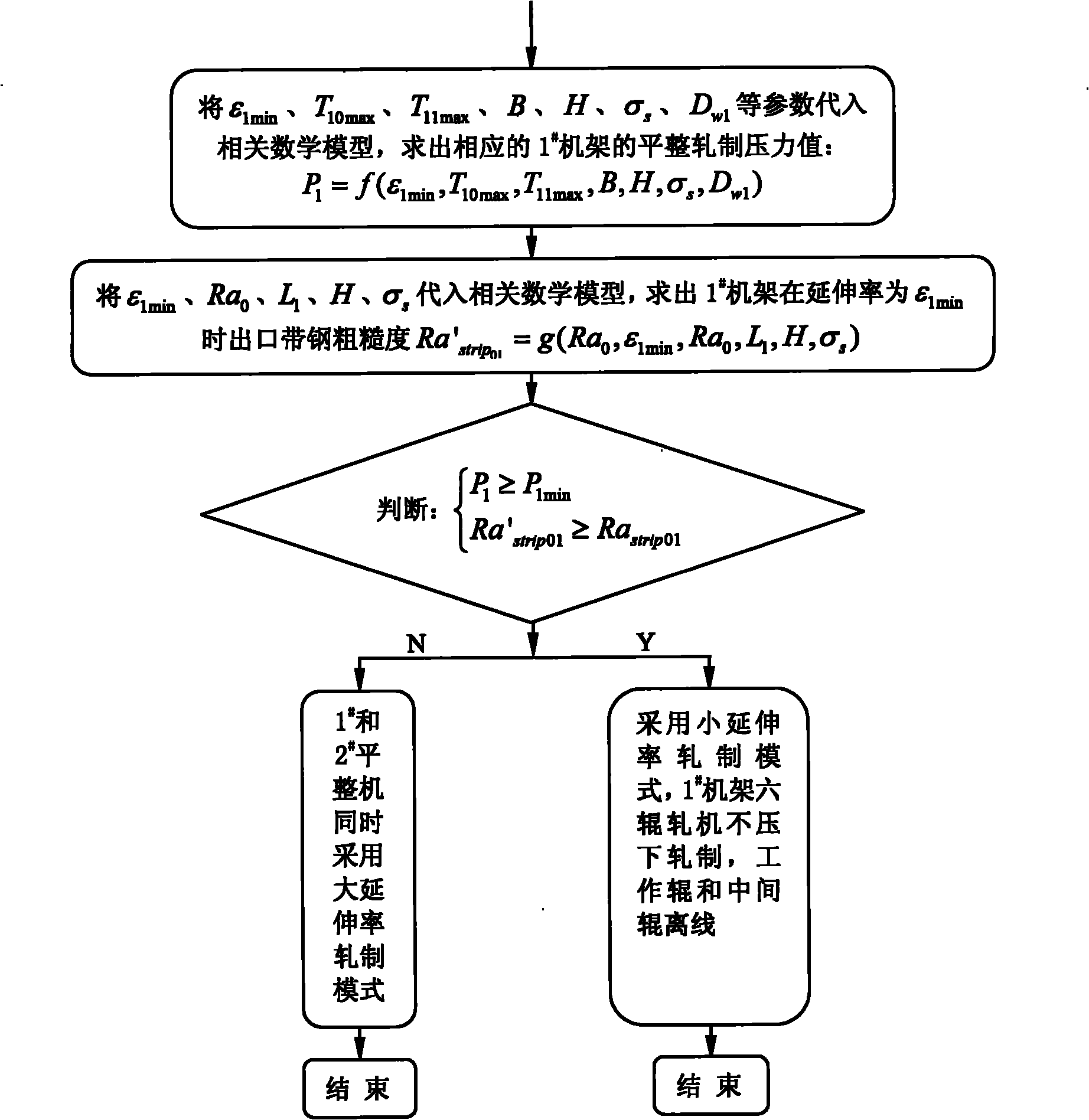

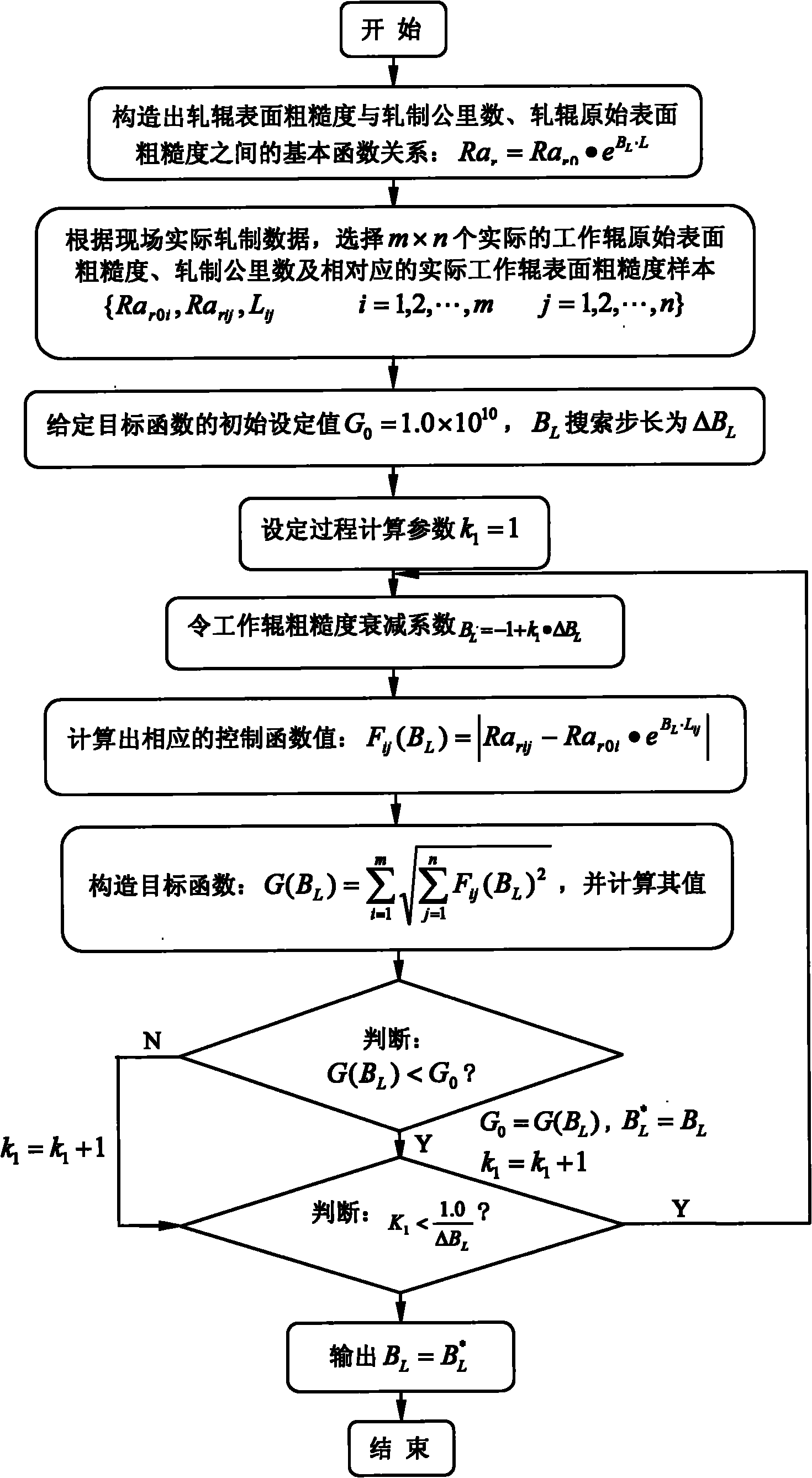

[0062] like figure 1 , as shown in 2 and 3, take the specification as 0.2*1020 and the steel type as MR2T3 (referred to as No. 1 typical specification product) as an example.

[0063] Step 1: Collect the equipment parameters of the double-frame leveling machine, mainly including: 1 # and 2 # Work roll diameter D of the frame w1 = 460mm, D w2 = 460mm; 1 # and 2 # Raw roughness Ra of work rolls of rack r1 =0.8μm, Ra r2 = 2.0 μm; 1 # and 2 # Rack work roll rolling kilometers L 1 =100Km, L 2 = 100Km.

[0064] Step 2: Collect the key rolling process parameters of the product to be leveled, for No. 1 typical specification product: strip thickness H 1 =0.2mm, width B 1 =1020mm, material (strength) σ s1 =292Mpa, allowable range of elongationε min1 = 0.8% with ε max1 =1.2%, target elongation ε o =1.0%, incoming material roughness Ra 01 =1.2μm, the allowable range of finished product roughness Ra 1min1 =0.6μm and Ra 1max1 =0.8μm, finished product target roughness Ra ...

Embodiment 2

[0103] like figure 1 , as shown in 2 and 3, take the specification as 0.5*800 and the steel type as IF steel (referred to as No. 2 typical specification product) as an example.

[0104] Step 1: consistent with Example 1.

[0105] Step 2: Collect the key rolling process parameters of the product to be leveled, for the No. 2 typical specification product: strip thickness H 2 =0.5mm, width B 2 =800mm, material (strength) σ s2 =160Mpa, allowable range of elongation ε min2 = 0.5% with ε max2 = 0.6%, target elongation ε o =0.55%, incoming roughness Ra 02 =1.5μm, the allowable range of finished product roughness Ra 1min2 =1.0μm and Ra 1max2 =1.2μm, finished product target roughness Ra o =1.1μm, allowable range of front tension T 21min2 =16Mpa and T 21max2 =32Mpa, medium tension allowable range T 11min2 =32Mpa and T 11max2 =64Mpa, allowable range of back tension T 10min2 =16Mpa and T 10max2 =32Mpa;

[0106] Step 3: Pass tests such as Figure 4 shown, giving 1 # and 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com