Packing box for freeze-dried powder bottle high-speed machine

A high-speed machine, freeze-dried powder technology, used in packaging, transportation and packaging, containers to prevent mechanical damage, etc. The effect of convenient molding, high packaging production capacity, independent and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

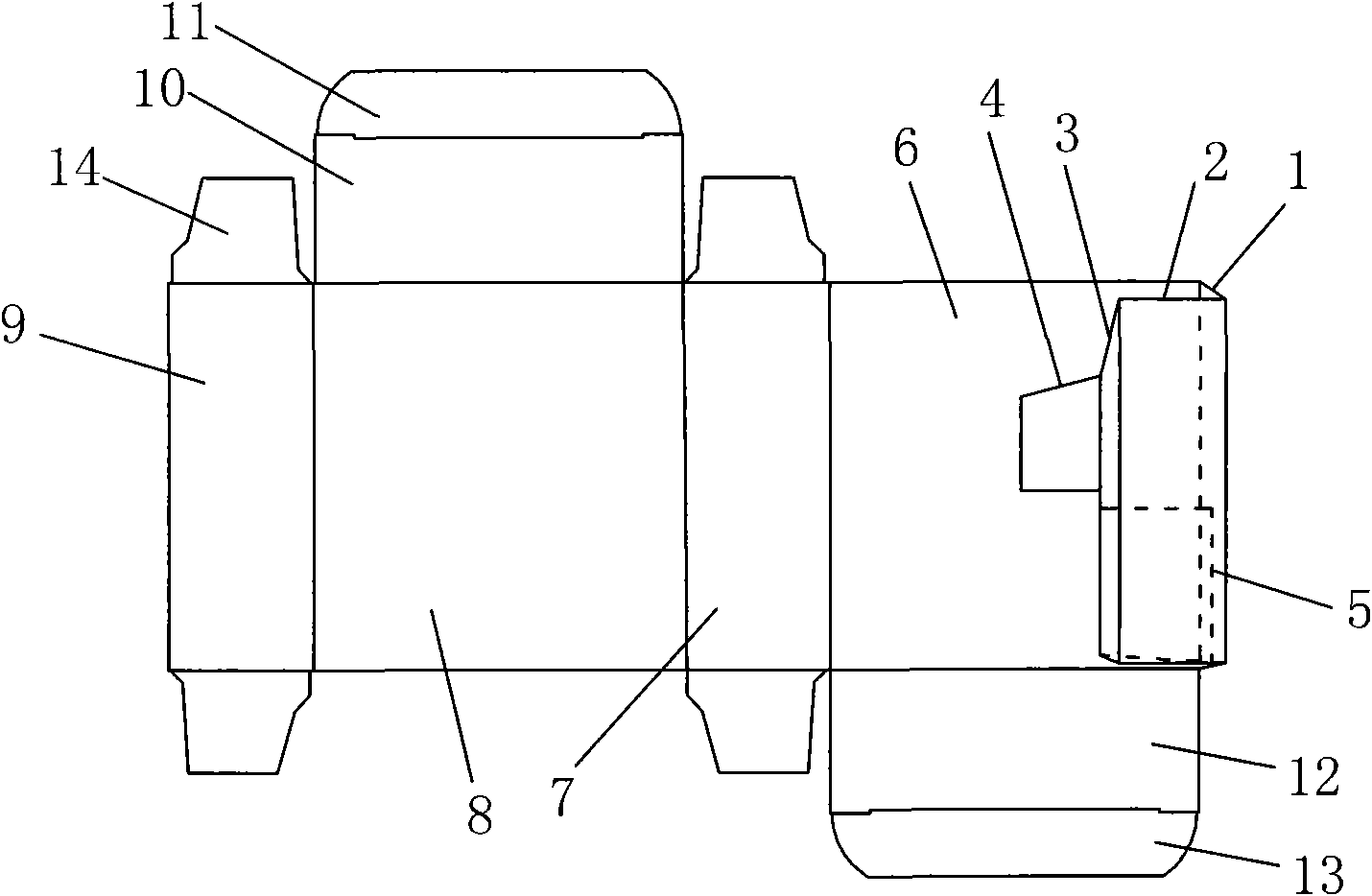

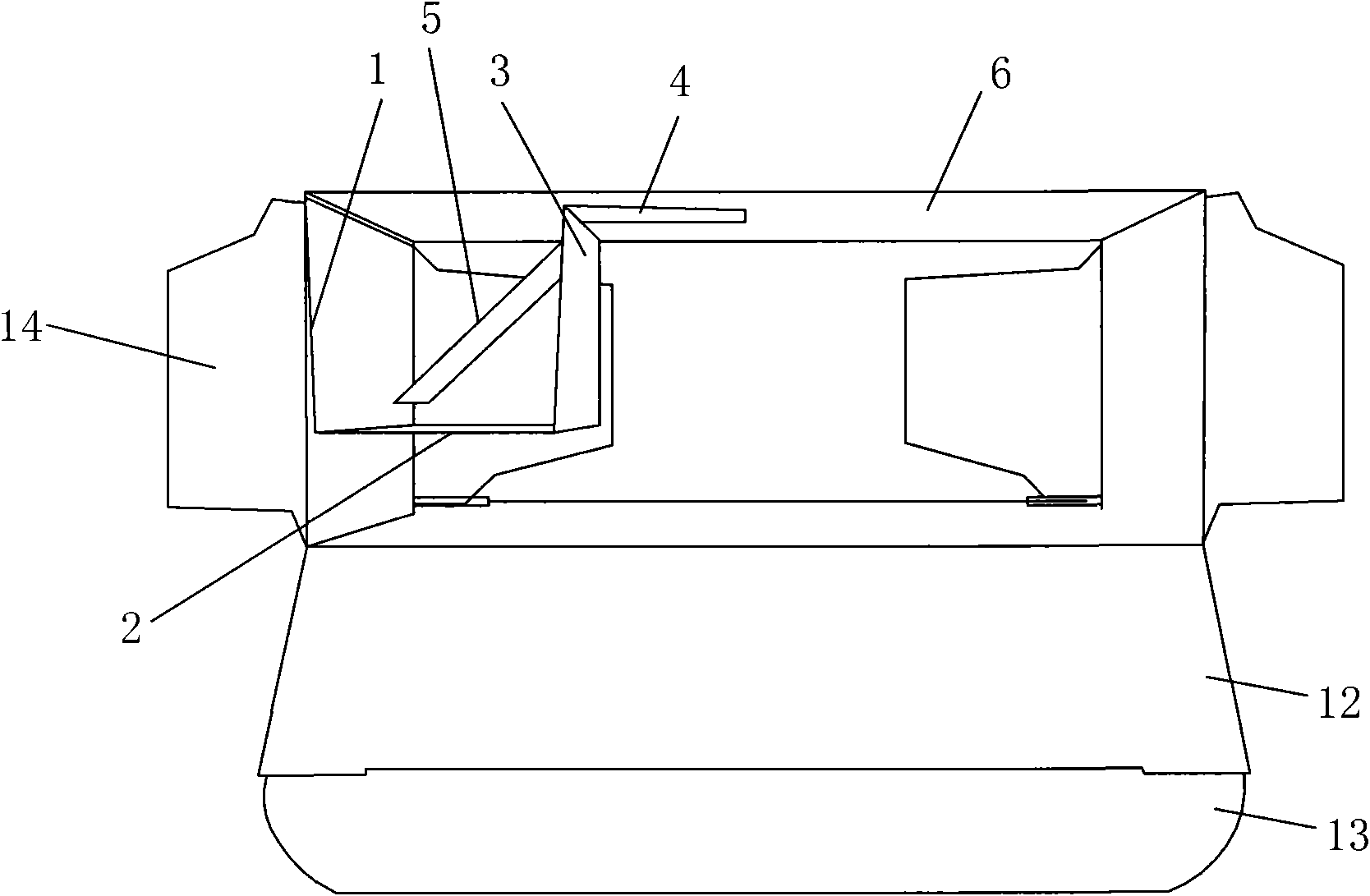

[0029] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a box body and a combination bracket connected with the box body as a whole and located on the left or right side inside the box body, and the box body and the combination bracket are unfolded from left to right The sheet is an integral sheet, and the box is in the shape of a cube. The box body includes four box walls connected to each other from left to right and bounded by vertical indentations, and the combined bracket is connected with the leftmost or rightmost box wall among the four box walls. Bonding bracket plate one 1, adjacent bracket plate one 2 connected with bonding bracket plate one 1, adjacent bracket plate two 3 connected with adjacent bracket plate one 2, and adjacent bracket plate two respectively 3 connected bonded carrier plate two 4 and inner bottle carrier plate 5, said bonded carrier plate one 1, adjacent carrier plate one 2, adjacent carrier plate two 3 and bond...

Embodiment 2

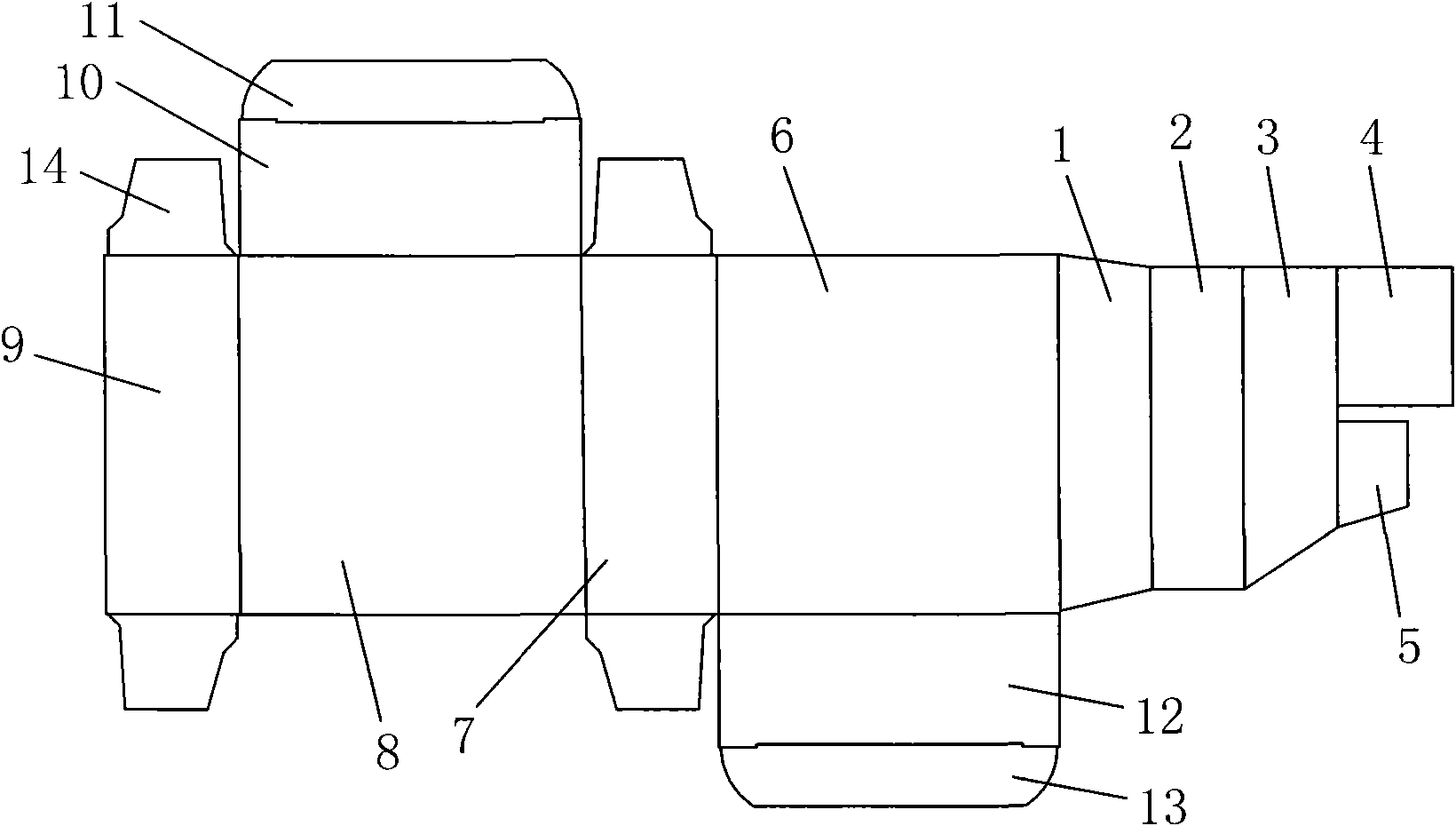

[0036] Such as Figure 4 As shown, in this embodiment, the difference from Embodiment 1 is that the bonded bracket plate 1, the adjacent bracket plate 1 2, the adjacent bracket plate 2 3 and the bonded bracket plate 2 4 are folded form Shape, the rest of the structure is the same as in Example 1.

[0037] During actual processing, first fold the indentation between the inner bottle bracket plate 5 and the adjacent bracket plate 2 3 inwardly by 180 degrees (you can also not perform this step), and then along the bonded bracket plate 1 and the adjacent bracket plate The indentation between the shelf boards 1 and 2 is folded inward by 180 degrees, so that the adhesive bracket board 2 4 is bonded and fixed with the auxiliary adhesive wall; subsequently, the indentations between the four box walls are used to fold in half respectively, and the adhesive The bracket plate-1 is bonded and fixed with the main sticking wall, and the above-mentioned processes are all automatically com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com