Method and device for polymerizing polyacrylonitrile spinning stock solution

A polymerization method and spinning dope technology, which are applied in the field of polymer solution polymerization, can solve the problems of short material residence time, difficult spinning dope, not universal application, etc., and achieve lower operating costs, stable product quality, and small footprint. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

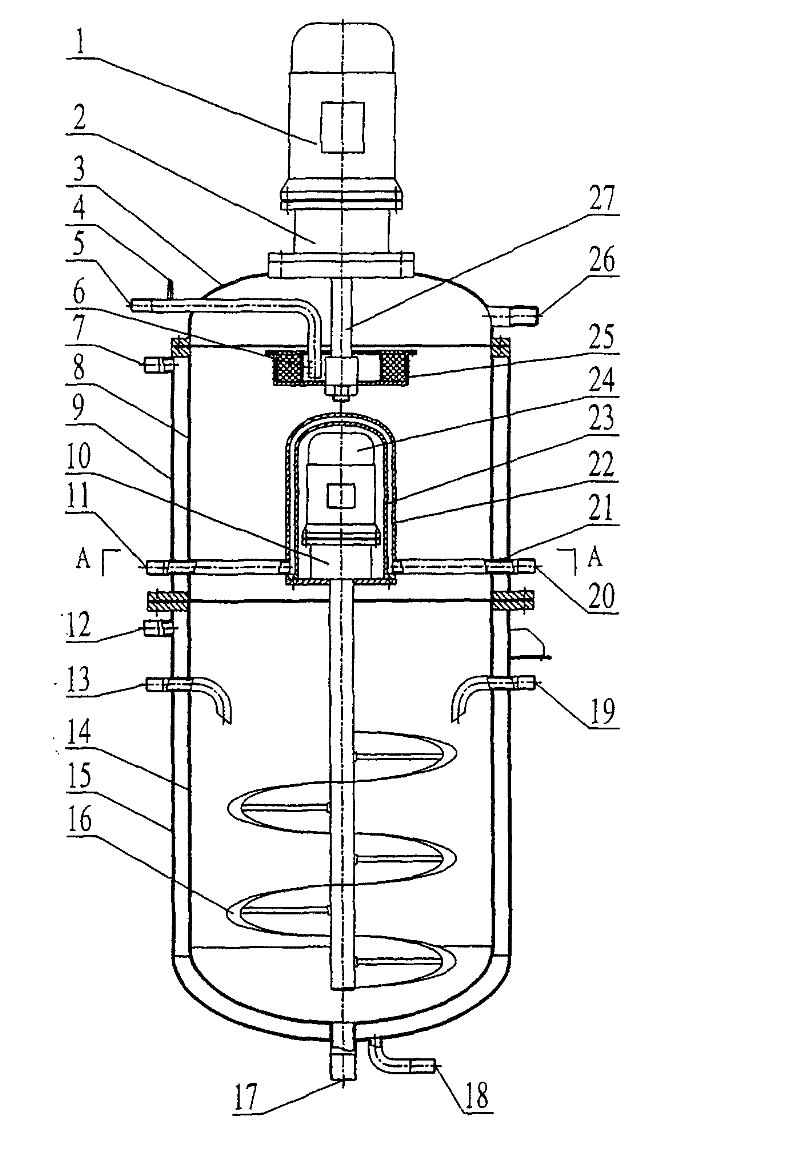

[0032] Example 1: 2323.2g of acrylonitrile, 48.4g of itaconic acid, 48.4g of methyl acrylate and 9900g of dimethyl sulfoxide were added to the mixing zone, powered by a gear pump, and the materials entered from the upper material inlet through a heat exchanger The rotor returns to the stirring area, so that the material circulates between the integrated supergravity polymerization reactor and the heat exchanger at a circulation rate of 50L / h, and is controlled by adjusting the flow rate of the temperature control jacket and the circulating water of the heat exchanger The temperature is at 60°C, and nitrogen is blown to drive oxygen for 20 minutes. Dissolve 21.68g of azobisisobutyronitrile into 1100g of dimethyl sulfoxide, add it into the material inlet pipe through the branch pipe on the material inlet, and spray it to the inner edge of the rotor with a speed of 1000 rpm through the liquid distributor. The rotor is installed concentrically The 5-layer porous plate with an open...

Embodiment 2

[0033] Embodiment 2: As described in Embodiment 1, the rotor speed is 500 rev / min, and other conditions remain unchanged. The measured product conversion rate is 95.1%, and the molecular weight distribution coefficient is 2.7.

Embodiment 3

[0034] Embodiment 3: As described in Embodiment 1, the initiator solution addition rate is 0.04 times of the material circulation flow rate, and other conditions remain unchanged, and the product conversion rate recorded is 95.6%, and the molecular weight distribution coefficient is 2.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com