Preheating type side-heating galvanizing furnace

A preheating furnace and furnace body technology, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems affecting the speed and quality of galvanizing, achieve good heat preservation and energy saving, uniform heating, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

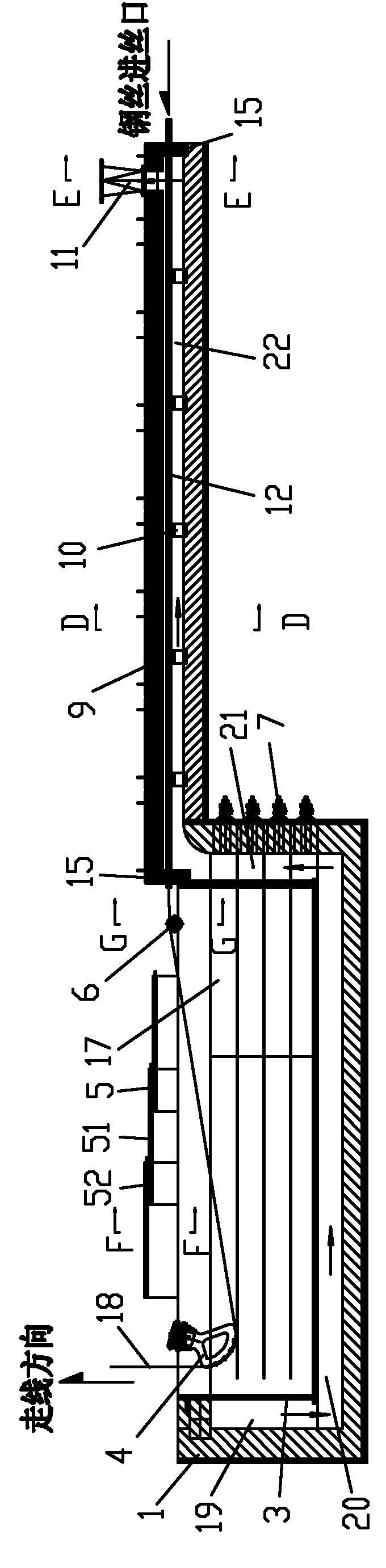

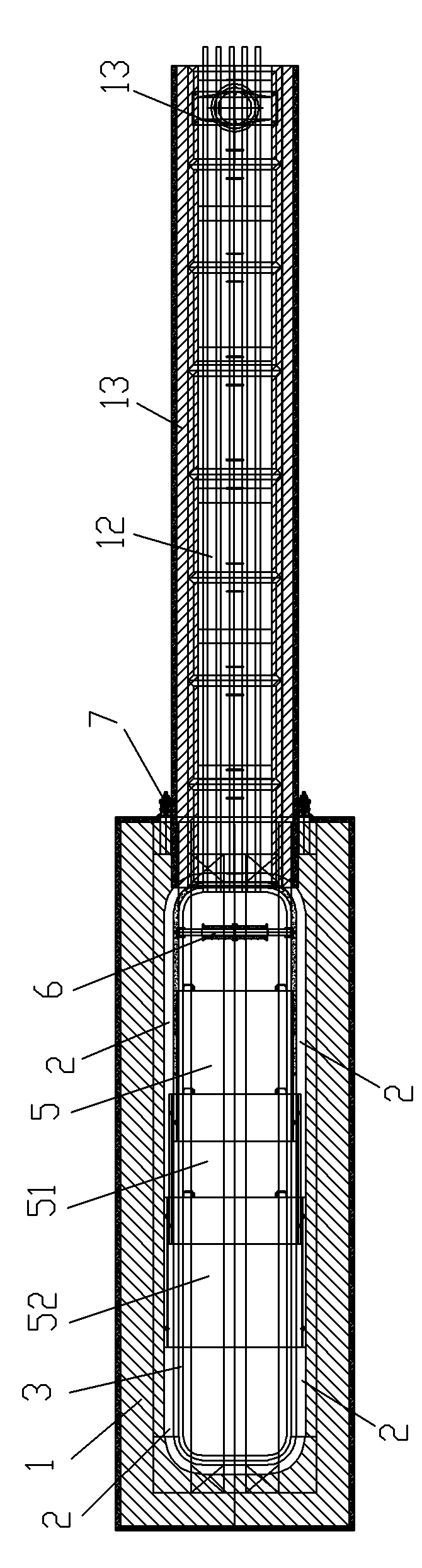

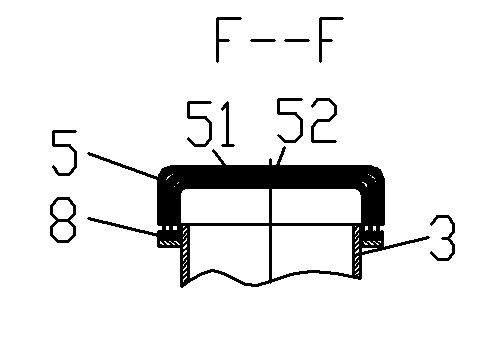

[0020] Among the figure: 1, furnace body, 2, the first fire path, 3, zinc pot, 4, pressure roller, 5, the first moving pot cover, 51, the second moving pot cover, 52, the third moving pot cover, 6 , wire pick roller, 7, burner, 8, slide rail, 9, top cover plate, 10, bracket brick, 11, chimney interface, 12, threading pipe, 13, preheating furnace body, 14, guide plate, 15. Sealing brick, 16. Protective layer, 17. Liquid zinc, 18. Steel wire, 19. Second fire path, 20. Third fire path, 21. Fourth fire path, 22. Preheating fire path, 23. Holder frame through holes.

[0021] The preheating side heating galvanizing furnace includes a furnace body 1 and a zinc pot 3 located in the furnace body 1. A burner 7 is arranged at the end of the furnace body 1, and there is a fire path between the furnace body 1 and the zinc pot 3. The flame ejected from the burner 7 enters the fire path; the first fire path 2 is set on both sides of the body of heater 1, the fourth fire path is set at the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com