Ground structure for building and construction technology of ground structure

A construction technology and building technology, applied in the direction of building structure, building, floor, etc., to achieve strong self-leveling, good heat storage effect, and reduce the bulk density of floor slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

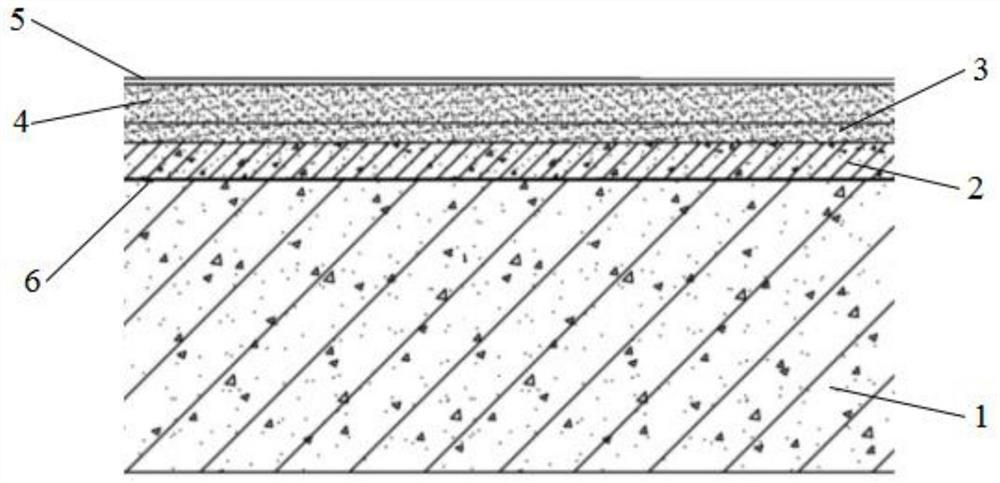

[0057] The embodiment of the invention discloses a ground structure for a building and its construction technology. The ground structure is as follows: figure 1 , including the floor of the original structure floor 1, also includes: bonding layer 2, insulation layer 3, concrete layer 4 and facing layer 5; its construction process is as follows:

[0058] (1) After cleaning the floor 1 of the original structure, check that its flatness is not greater than 4mm / 2m;

[0059] (2) Brush one deck interface agent 6 on the floor 1 of the original structure;

[0060] (3) After the interface agent 6 is dried and solidified, a 10mm thick silica sol adhesive 2 is laid, and before the adhesive layer 2 is solidified, the extruded polystyrene board on the insulation layer 3 is bonded firmly, wherein the thickness of the insulation layer is 9.5 mm, and during the laying of the insulation layer 3, ensure that the joint width between adjacent insulation boards is 0-1mm, and the flatness is not l...

Embodiment 2

[0064] A ground structure for a building building and a construction process thereof, which are different from Embodiment 1 in that:

[0065] (1) In step (3), the thickness of the bonding layer is 8mm;

[0066] (2) In the step (3), the insulation layer thickness is 13mm;

[0067] (3) The thickness of the concrete layer in step (4) is 25mm.

Embodiment 3

[0069] A ground structure for a building building and a construction process thereof, which are different from Embodiment 1 in that:

[0070] (1) In step (3), the thickness of the bonding layer is 6.5mm;

[0071] (2) In the step (3), the insulation layer is a cross-linked polyethylene cushion, and the thickness is 20mm;

[0072] (3) The thickness of the concrete layer in step (4) is 35mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com