Dovetailing cold-rolled steel composite plate

A technology of cold-formed steel and composite panels, which is applied to roofs, building components, and roof coverings that use flat/curved panels, and can solve the problem of not having the strength of cold-formed dovetail steel plates, not having insulation materials and cold-formed dovetail steel plate insulation Function and other issues, to achieve the effect of improving strength, bending resistance and fracture resistance, improving anti-leakage performance, and improving connection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

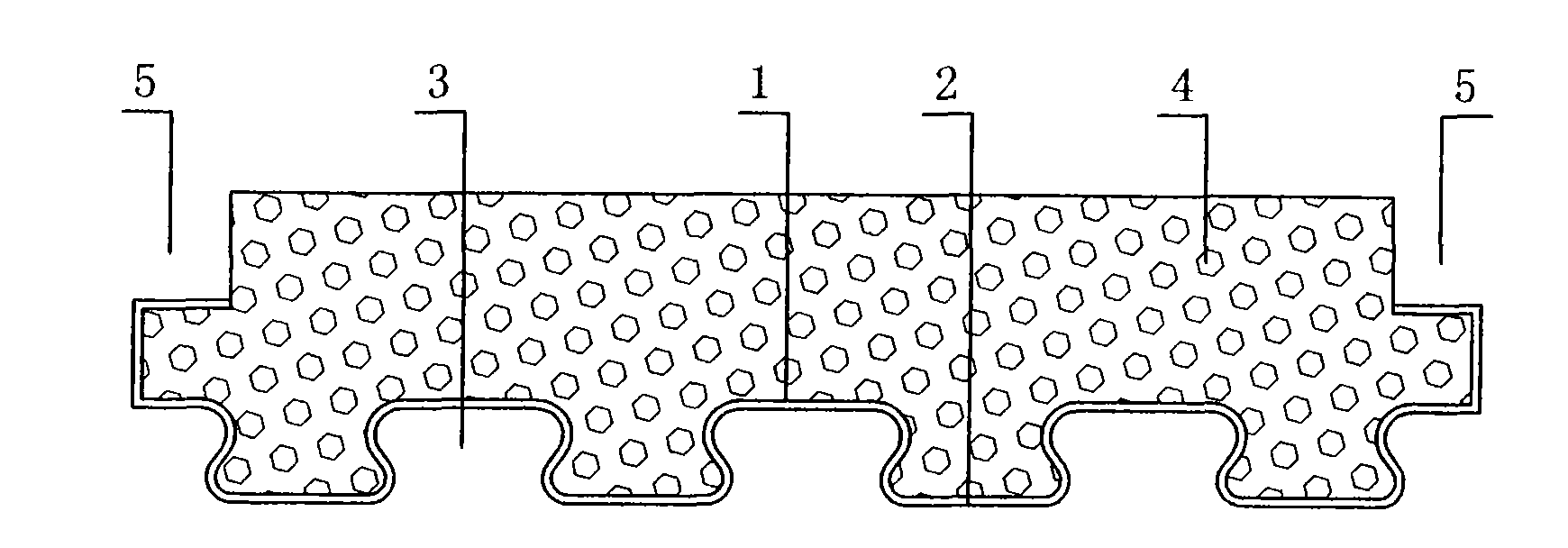

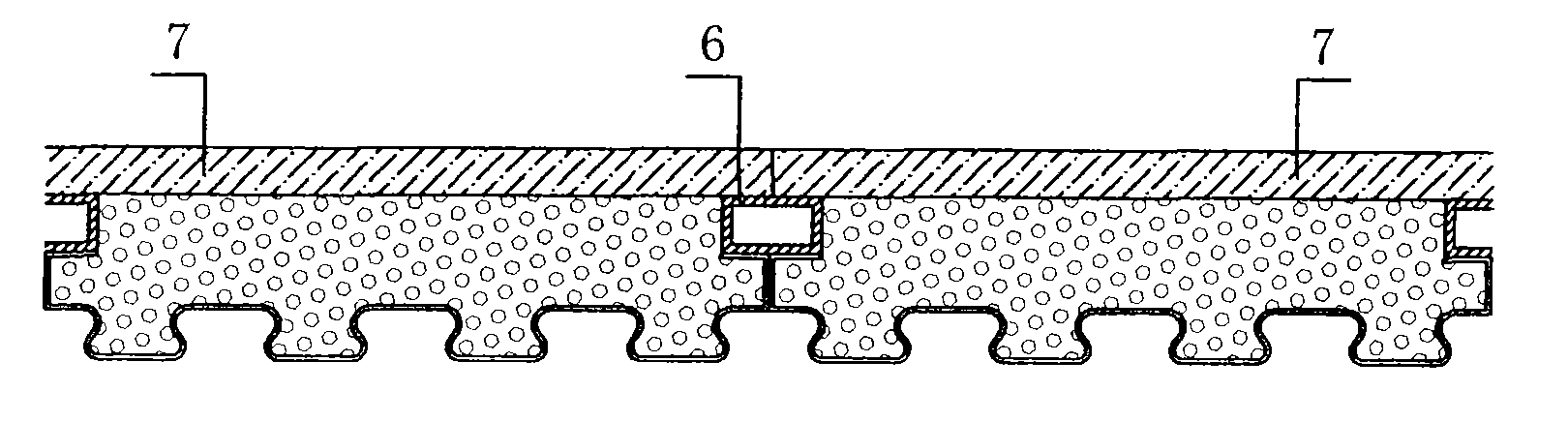

[0041] The structure diagram of the end face of the dovetail cold-formed steel composite plate filled with light inorganic materials is as follows figure 1 as shown, figure 2 yes figure 1 Assembly structure diagram, in which: 1 is dovetail cold-formed steel plate, 2 is upper dovetail groove of dovetail cold-formed steel plate, 3 is lower dovetail groove of dovetail cold-formed steel plate, 4 is light inorganic insulation material, 5 is connection groove, 6 is square steel pipe , 7 is an interior trim panel.

[0042] When manufacturing light-weight inorganic material filled dovetail cold-formed steel composite panels, first, put dovetail cold-formed steel plate 1 into the mold, and pour light inorganic thermal insulation material 4 in the direction of dovetail groove 2 on the dovetail cold-formed steel plate, light inorganic thermal insulation The material 4 is filled into the dovetail groove on the dovetail cold-formed steel plate, and the dovetail cold-formed steel plate 1...

Embodiment 2

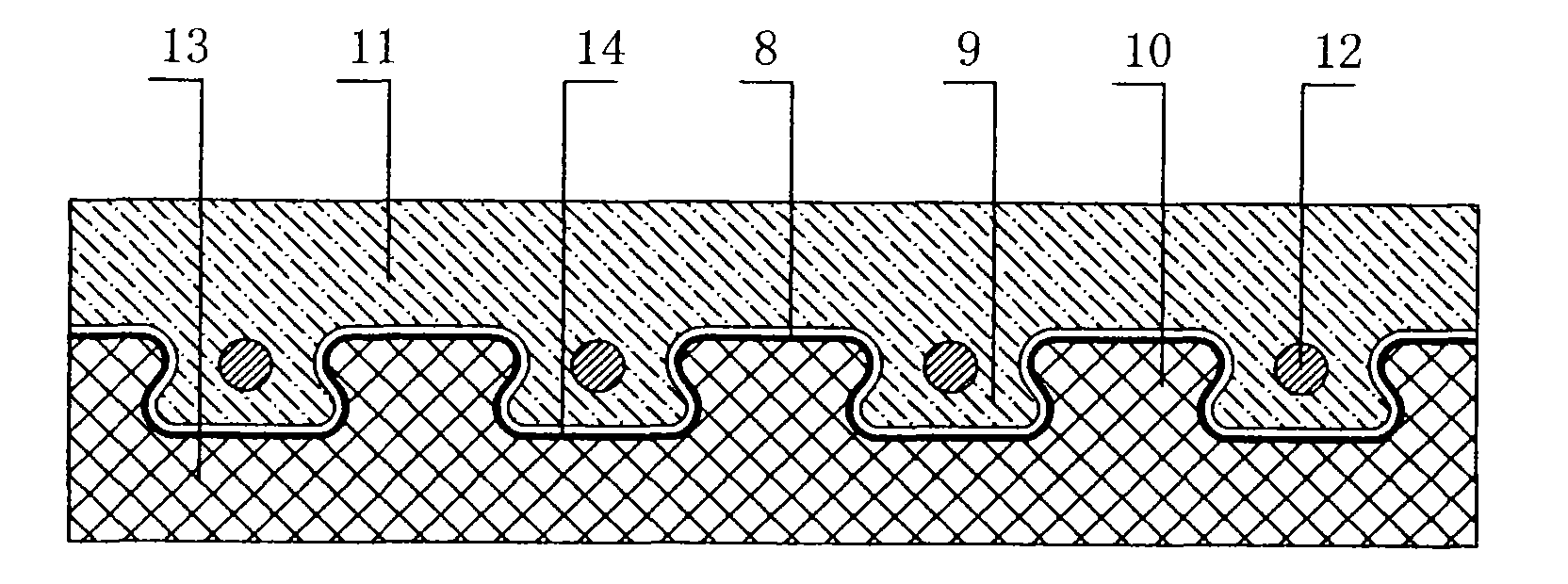

[0046] The structure diagram of the end face of the dovetail cold-formed steel composite panel filled with cement and wood-plastic panels on both sides is as follows image 3 As shown, among them: 8 is the dovetail cold-formed steel plate, 9 is the upper dovetail groove of the dovetail cold-formed steel plate, 10 is the lower dovetail groove of the dovetail cold-formed steel plate, 11 is cement, 12 is connecting steel bar, 13 is wood-plastic board, and 14 is glue .

[0047] When manufacturing lightweight inorganic materials and wood-plastic panels double-sided filled dovetail cold-formed steel composite panels, firstly, the surface of the prefabricated wood-plastic panel 13 is glued 14 and then inserted into the upper dovetail groove 9 of the dovetail cold-formed steel plate 8, and the wood-plastic panel 13 and the dovetail cold-formed steel plate 8 are put into the mould, and the connecting steel bar 12 is put in, and the cement 11 is poured into the dovetail groove 9 on the ...

Embodiment 3

[0049] The structure diagram of the end face of the dovetail cold-formed steel composite plate filled with light inorganic materials and cement on both sides is as follows Figure 4 As shown, among them: 15 is the dovetail cold-formed steel plate, 16 is the upper dovetail groove of the dovetail cold-formed steel plate, 17 is the lower dovetail groove of the dovetail cold-formed steel plate, 18 is a cement board, 19 is a connecting steel bar, 20 is a light inorganic material, 21 is the connection slot.

[0050] When manufacturing lightweight inorganic materials and double-sided cement dovetail cold-formed steel composite panels, first, put the dovetail cold-formed steel plate 15 into the mold, put the connecting steel bars 19, and pour cement into the dovetail groove 16 on the dovetail cold-formed steel plate 18. Cement 18 is filled into the dovetail groove 16 on the dovetail cold-formed steel plate 15, the dovetail cold-formed steel plate 15 and the cement 18 are connected int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com