Eddy current sensor for detecting metal gap and defect under high-temperature and narrow-slit condition

An eddy current sensor and defect detection technology, applied in the field of detection, can solve the problems of being susceptible to interference, inability to measure, and high frequency of input signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

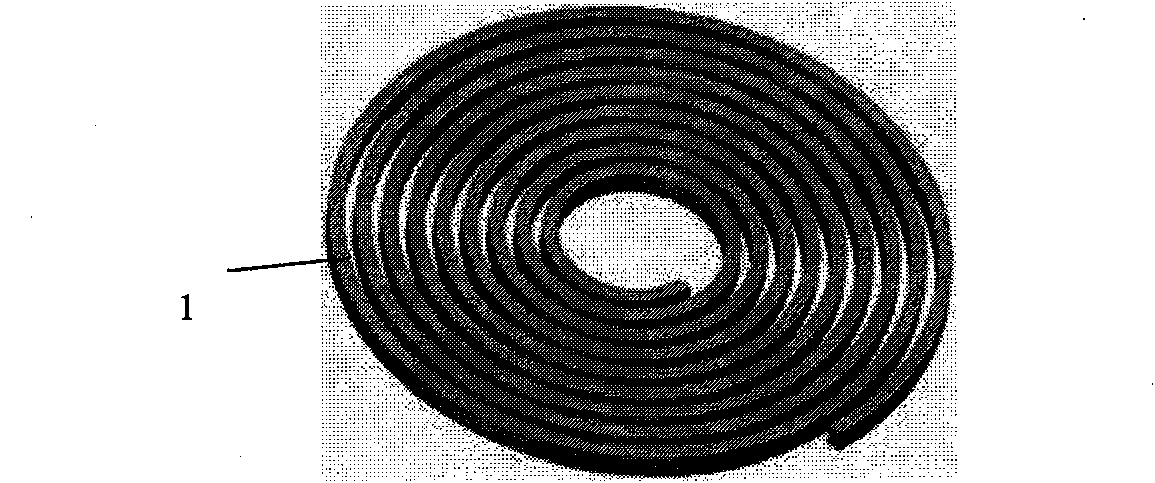

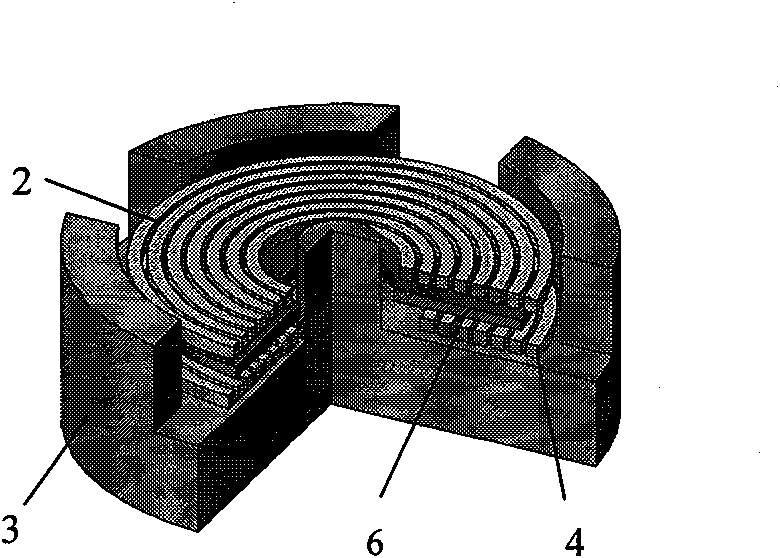

[0014] figure 1 , is the structure of the sensor microplanar coil. The material is nickel, which is produced by ultraviolet lithography and electroforming technology.

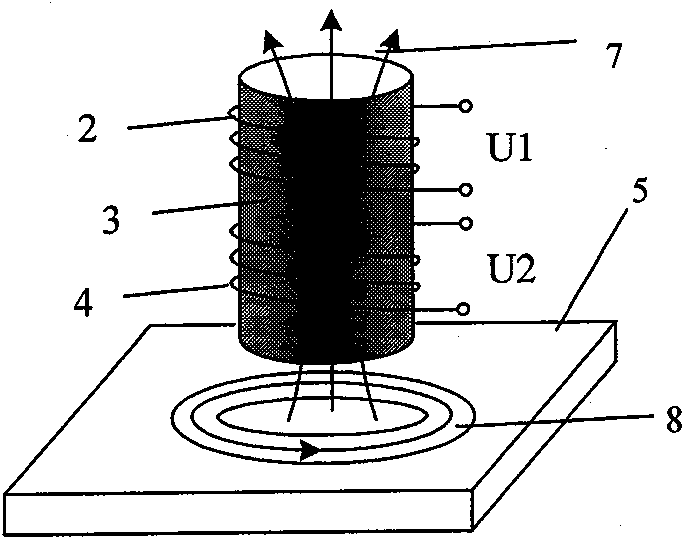

[0015] figure 2 , for the working principle of the sensor, the driving coil 2 and the sensitive coil 4 are installed in the iron core 3, and an AC excitation signal is input at both ends of the coil, and an induced voltage signal will be generated in the sensitive coil 4. When the gap between the measurement target 5 and the sensor changes or the measurement target 5 When there is a defect on the surface, the signal at both ends of the sensitive coil 4 will change. By reading the output signal of the sensitive coil 4, the size of the gap between the measurement target 5 and the sensor or the surface defect information of the measurement target 5 can be determined.

[0016] Concrete implementation steps of the present invention are:

[0017] 1. Firstly, the driving coil 2 and the sensitive coil 4 are made, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com