Lithium cell safety valve

A technology for safety valves and lithium batteries, which is applied to battery components, circuits, electrical components, etc., can solve problems such as battery leakage, and achieve the effects of reducing damage, improving reliability, and enhancing overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

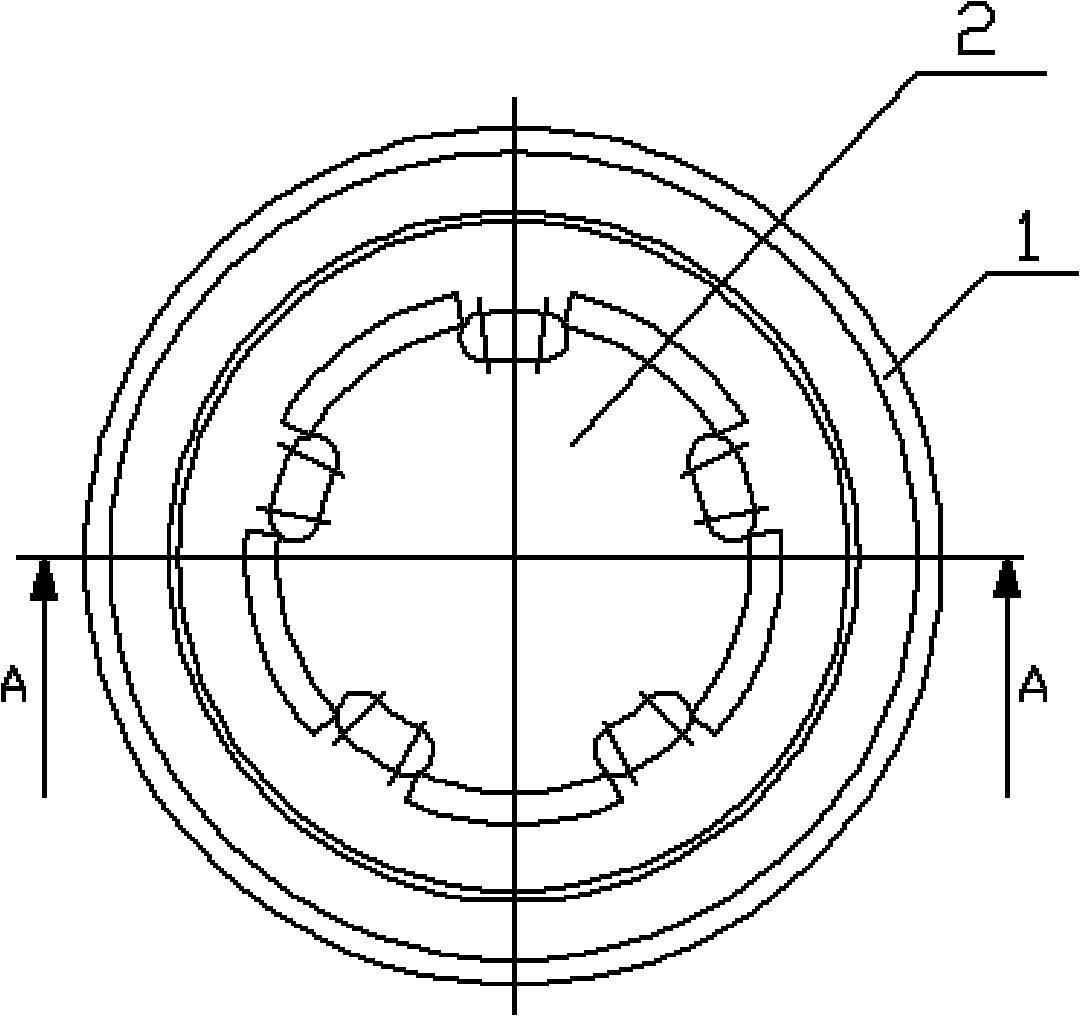

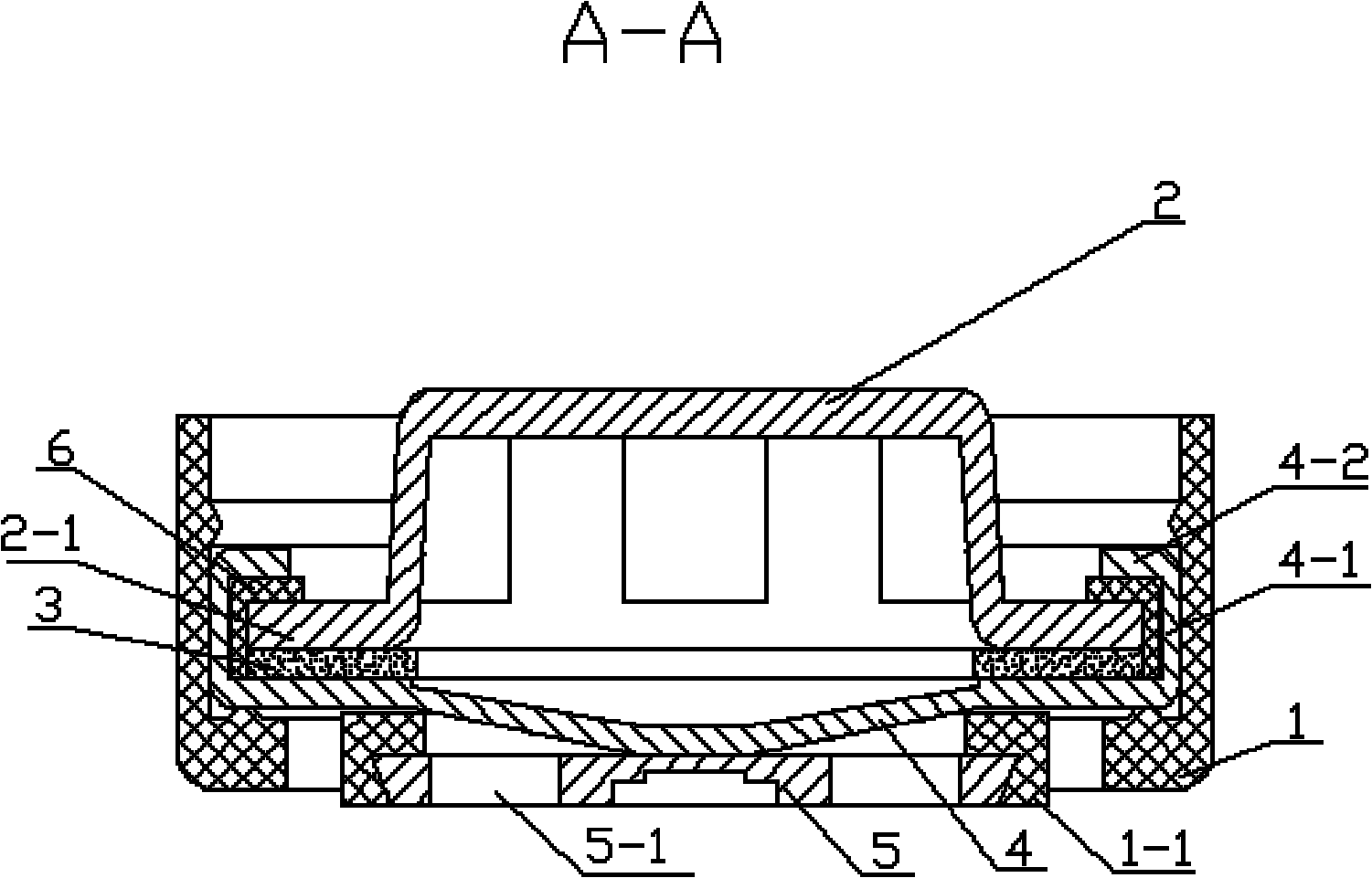

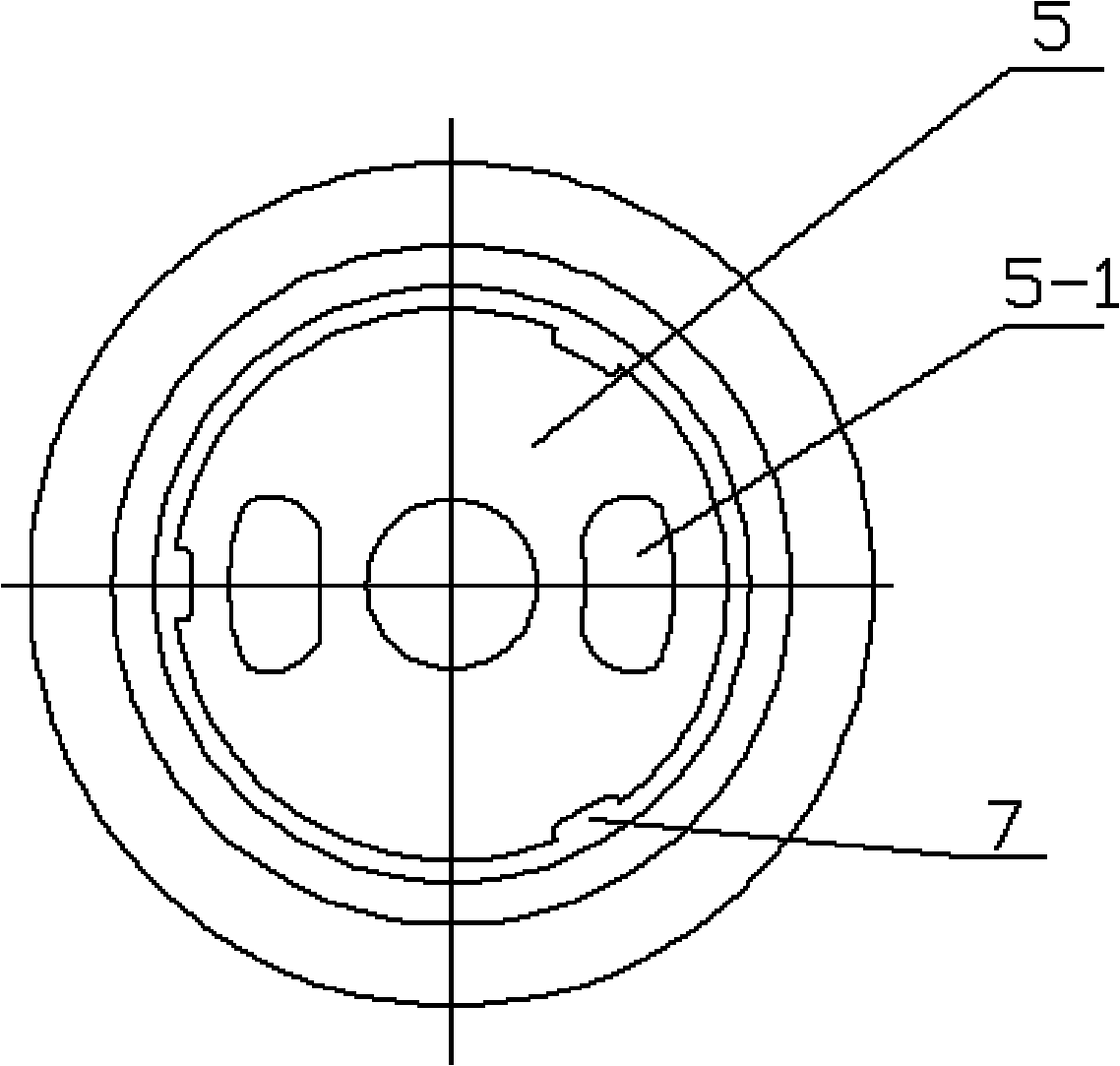

[0026] See Figure 1 to Figure 3 , The lithium battery safety valve of this embodiment includes a sealing ring 1, a top cover 2, a PTC ring 3, an explosion-proof diaphragm 4, an orifice plate 5, an insulating layer 6 and a connection point 7.

[0027] The top cover 2, the PTC ring 3, the explosion-proof diaphragm 4 and the orifice plate 5 are sequentially arranged inside the sealing ring from top to bottom. The orifice plate 5 and the explosion-proof diaphragm 4 are connected by ultrasonic welding, or by conductive glue, or by stamping, or by laser welding or resistance welding. The horizontal buckle end 4-2 of the explosion-proof diaphragm 4 is buckled to the top of the periphery 2-1 of the top cover 2, and the vertical buckle end 4-1 and the horizontal buckle end 4-2 are connected to the periphery 2-1 of the top cover 2. And the outside of the edge of the PTC ring 3 forms a hemming. The outside of the periphery 2-1 of the top cover 2 is aligned with the outer edge of the P...

Embodiment 2

[0030] See Figure 4 , The rest of this embodiment is the same as that of Embodiment 1, except that the sealing ring 1 and the insulating pad 1-1 are connected by three connecting ribs 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com