Automatic quick-change fixture tray

A technology for quick-change fixtures and pallets, applied in the direction of chucks, manufacturing tools, manipulators, etc., can solve the problem of taking a long time to operate, and achieve the effect of lightening the load, reducing the load and improving the production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

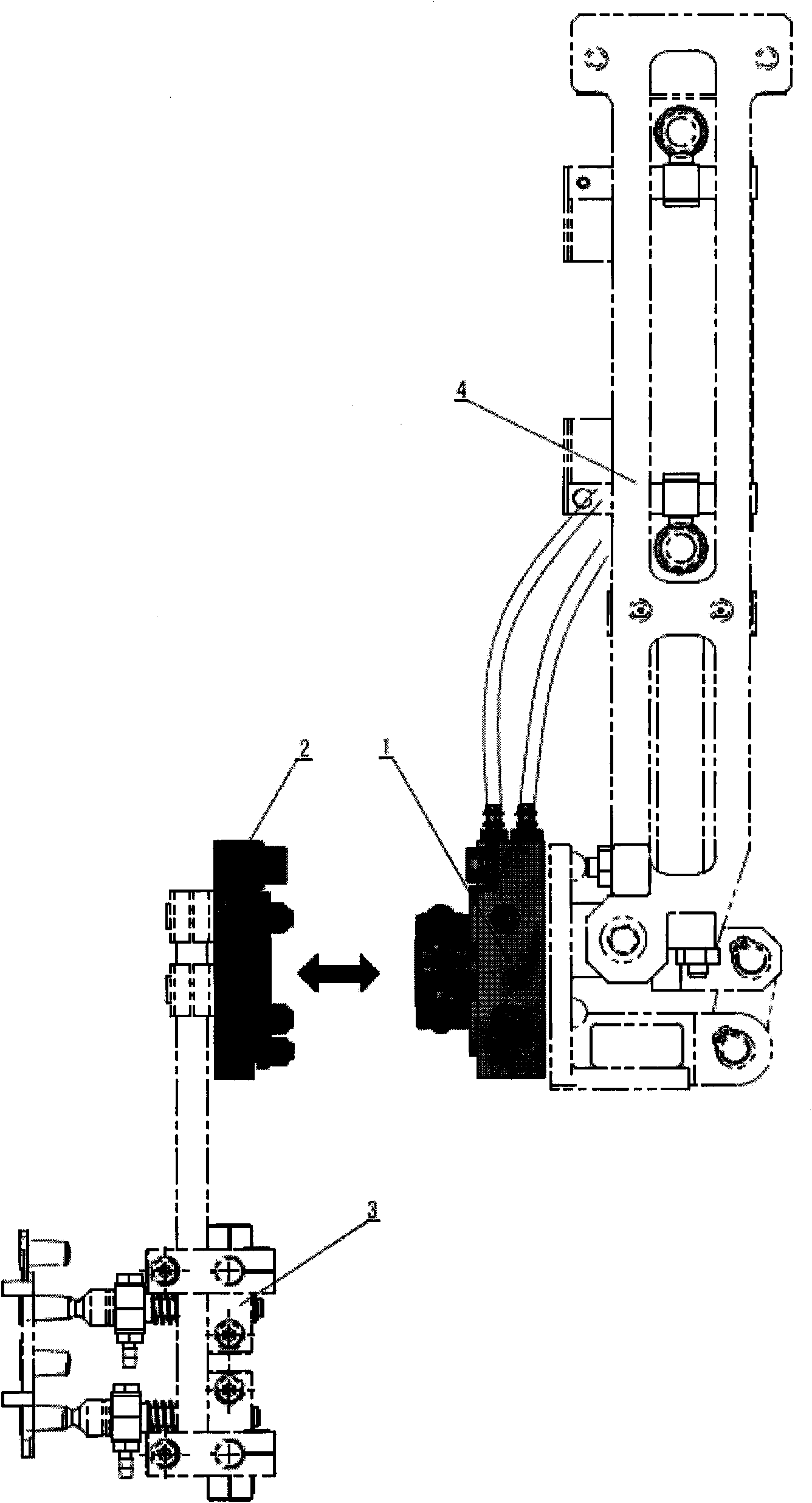

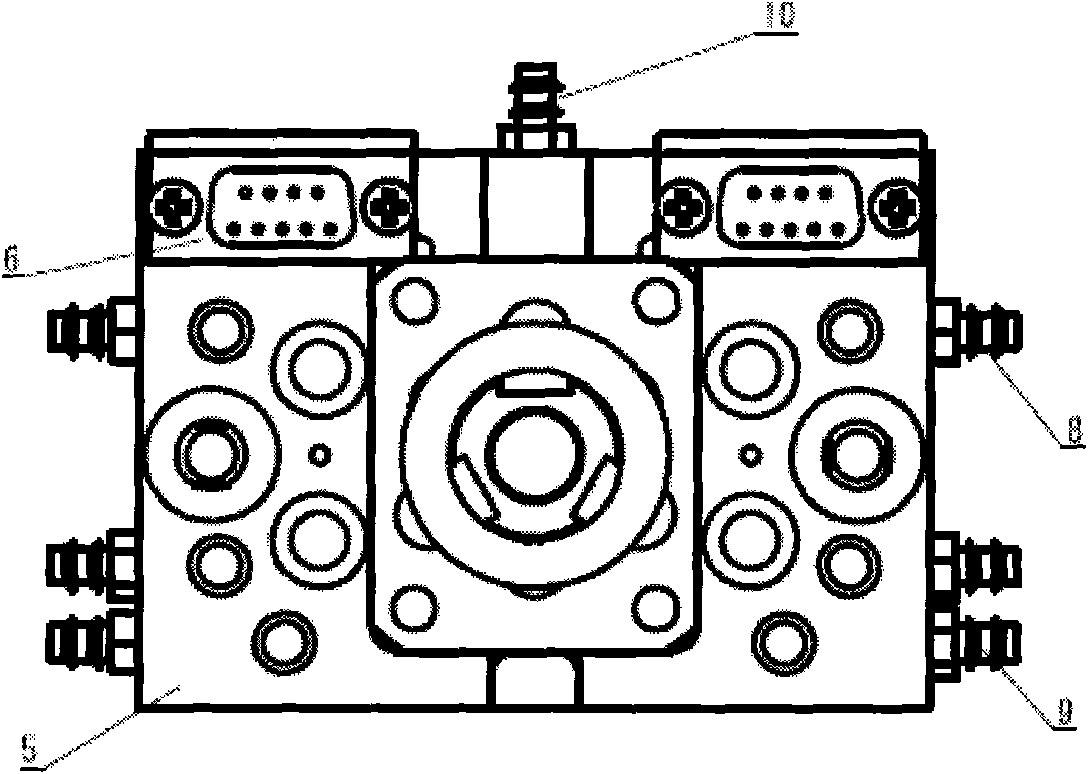

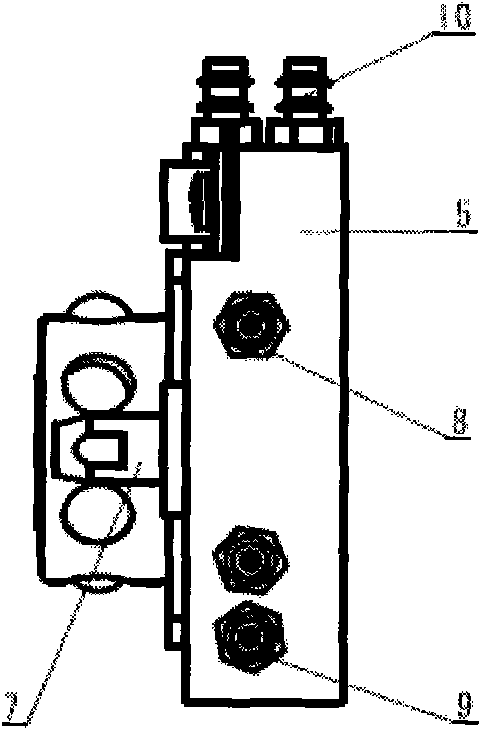

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the mechanical side tray 1 is installed on the mechanical arm 4, the fixture side tray 2 is connected to the fixture plate 3, the machine side tray body 5 and the fixture side tray body 11 are made of aluminum material, and are formed by hard oxidation, which can reduce the The load-bearing of the mechanical arm, while the strength and service life are also guaranteed, these two parts can realize the precision between the fixture plate 3 and the mechanical arm 4 through the connection of the D-SUB plug 6 on the mechanical side tray and the D-SUB socket 13 on the fixture side tray. Positioning and firm connection and fast separation, and realize the connection and disconnection of pneumatic signals and electrical signals at the same time, the mechanical side tray 1 and the fixture side tray 2 are interchangeable, and the same mechanical side tray 1 can correspond to multiple fixture side trays...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com