Automatic oiling machine

An oil filling machine, automatic technology, applied in bottle filling, liquid bottling, packaging and other directions, can solve the problems of insufficient precision, complex structure, fixed filling position, etc., to improve work efficiency, save human resources, and ensure the quality of oil filling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

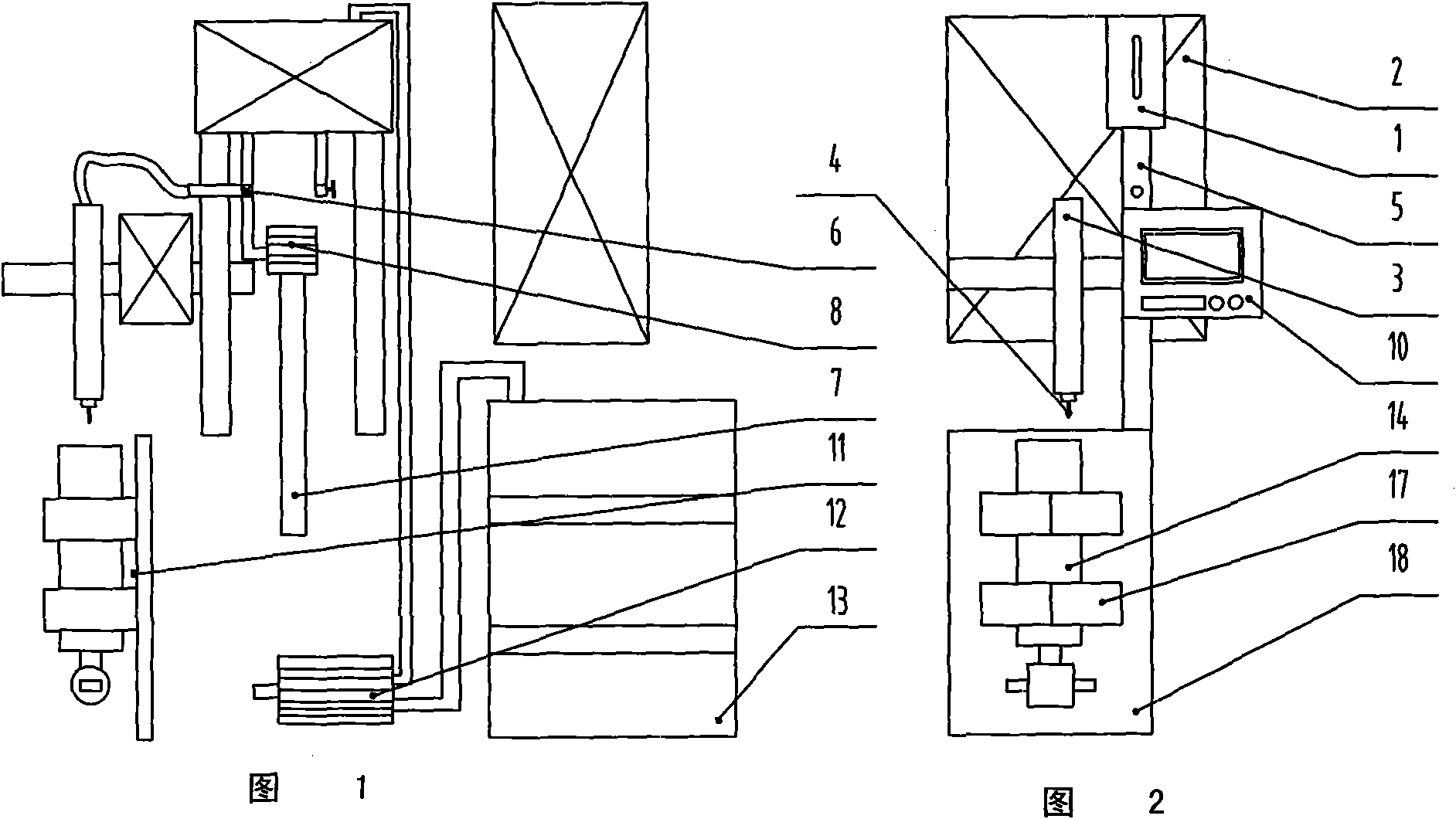

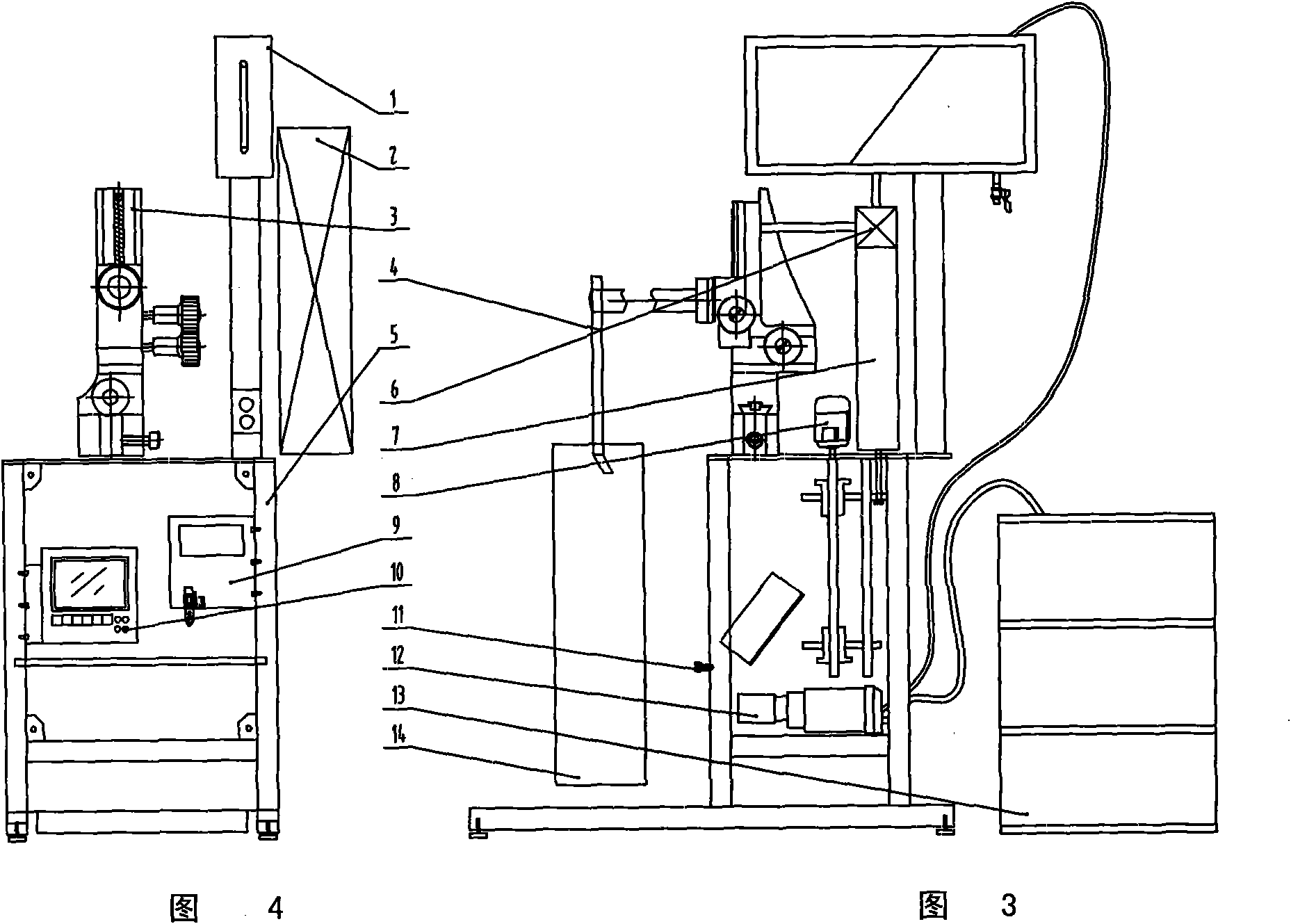

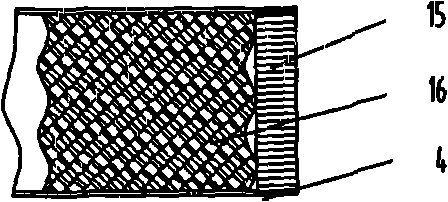

[0022] The basic structure of the automatic oiling machine of the present embodiment is as follows: Figure 1 to Figure 4 As shown, the positioning tool 17 is used to fix the reducer 14. The fuel tank 1 and the three-dimensional oiling arm 3 driven by the corresponding servo motor 8 through the transmission mechanism are placed on the fuel tank frame 5 above the positioning tooling 17. The three-dimensional oiling arm 3 is equipped with The terminal oil injection pipe 4 constitutes a three-axis manipulator similar to a common three-dimensional motion mechanism such as a coordinate measuring instrument. The oil outlet of the oil tank 1 is connected to the terminal oil filling pipe 4 through the three-way solenoid valve 6 controlled by the control circuit. One of the outlets of the three-way electromagnetic valve is connected to the terminal oil injection pipe 4, and the other is connected to the metering oil pump 7. The controlled end of each servo motor 8 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com