Multi-element compound diammonium phosphate and production method and system thereof

A compound diammonium phosphate, the technology of the manufacturing method, applied in the directions of ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, phosphate fertilizer, etc., can solve the problems of single component, insufficient nutrients for crops, easy loss of diammonium phosphate, etc. The effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

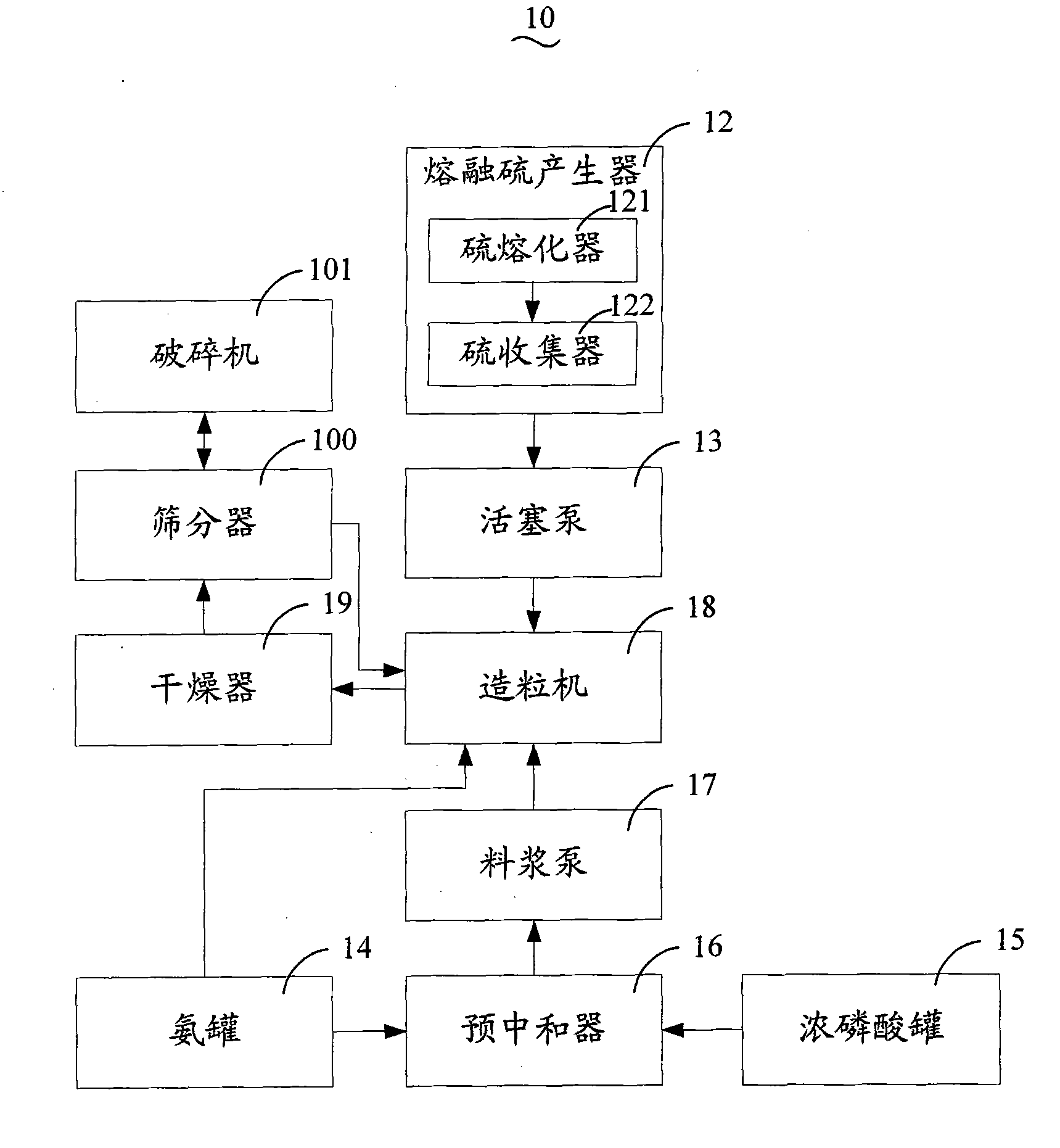

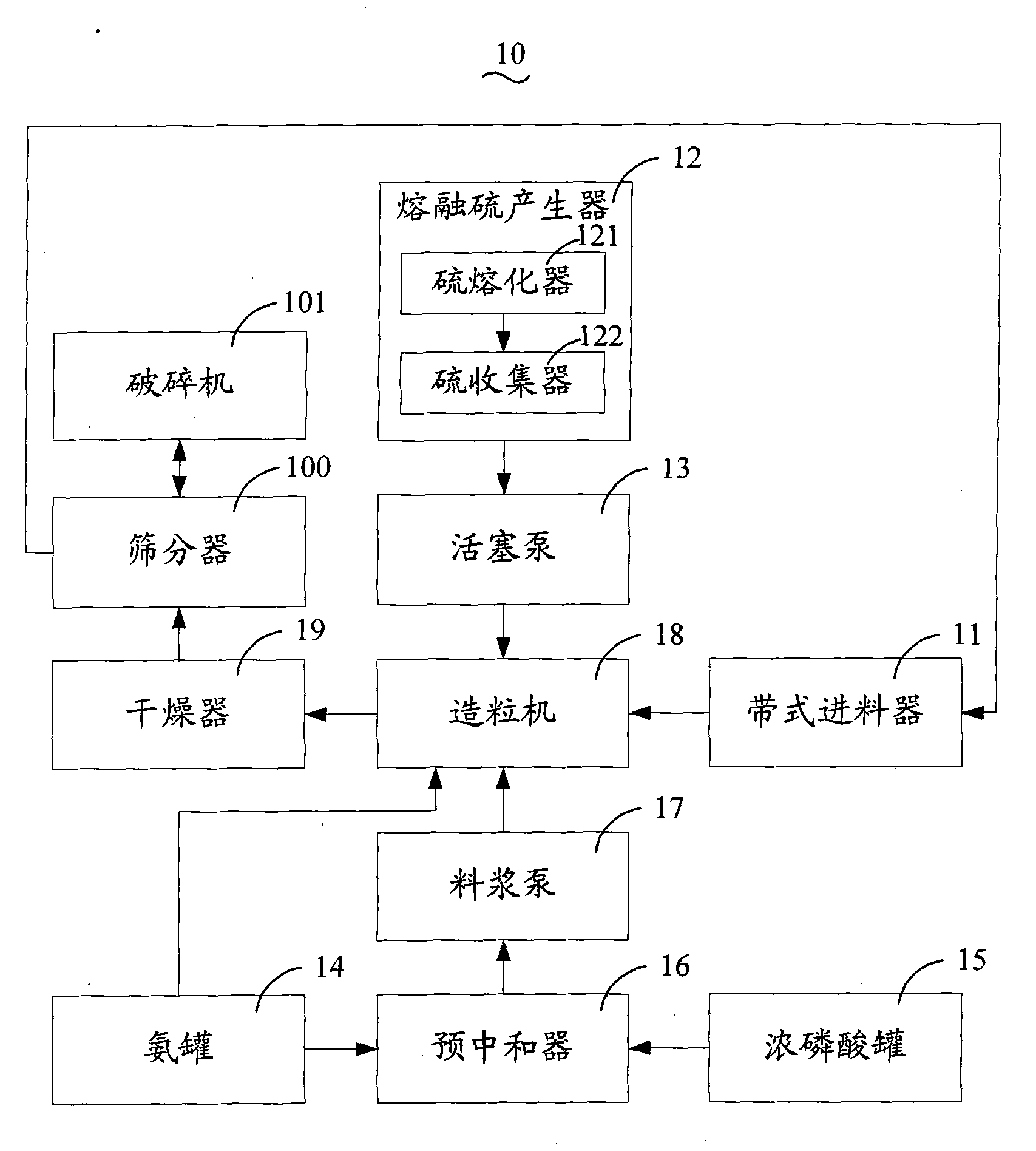

[0021] Please see figure 1 and figure 2 , the multi-element compound diammonium phosphate manufacturing system 10 comprises a molten sulfur generator 12, a piston pump 13, an ammonia tank 14, a concentrated phosphoric acid tank 15, a pre-neutralizer 16, a slurry pump 17, a granulator 18, a drier 19, A sifter 100 and a crusher 101.

[0022] The pre-neutralizer 16 is connected with the ammonia tank 14, the concentrated phosphoric acid tank 15 and the slurry pump 17, and is used to mix the ammonia gas provided by the ammonia tank 14 with the concentrated phosphoric acid provided by the concentrated phosphoric acid tank 15 to obtain a slurry including diammonium phosphate.

[0023] The slurry pump 17 is used to transport the slurry into the granulator 18 in the form of a spray.

[0024] The granulator 18 is used to granulate the slurry, ammonia gas, nutrient salt and elemental sulfur to form a multi-element composite diammonium phosphate assembly. In this embodiment, the granu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com