Method for purifying hyaluronic acid by pre-laying filter aid

A technology of hyaluronic acid and filter aid, which is applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of reducing the adsorption and filtering effect of diatomite, reducing the light transmittance of the liquid medicine, and not involving them. The effect of reducing the content of bacterial endotoxin, increasing the effect of filtering and adsorption, and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

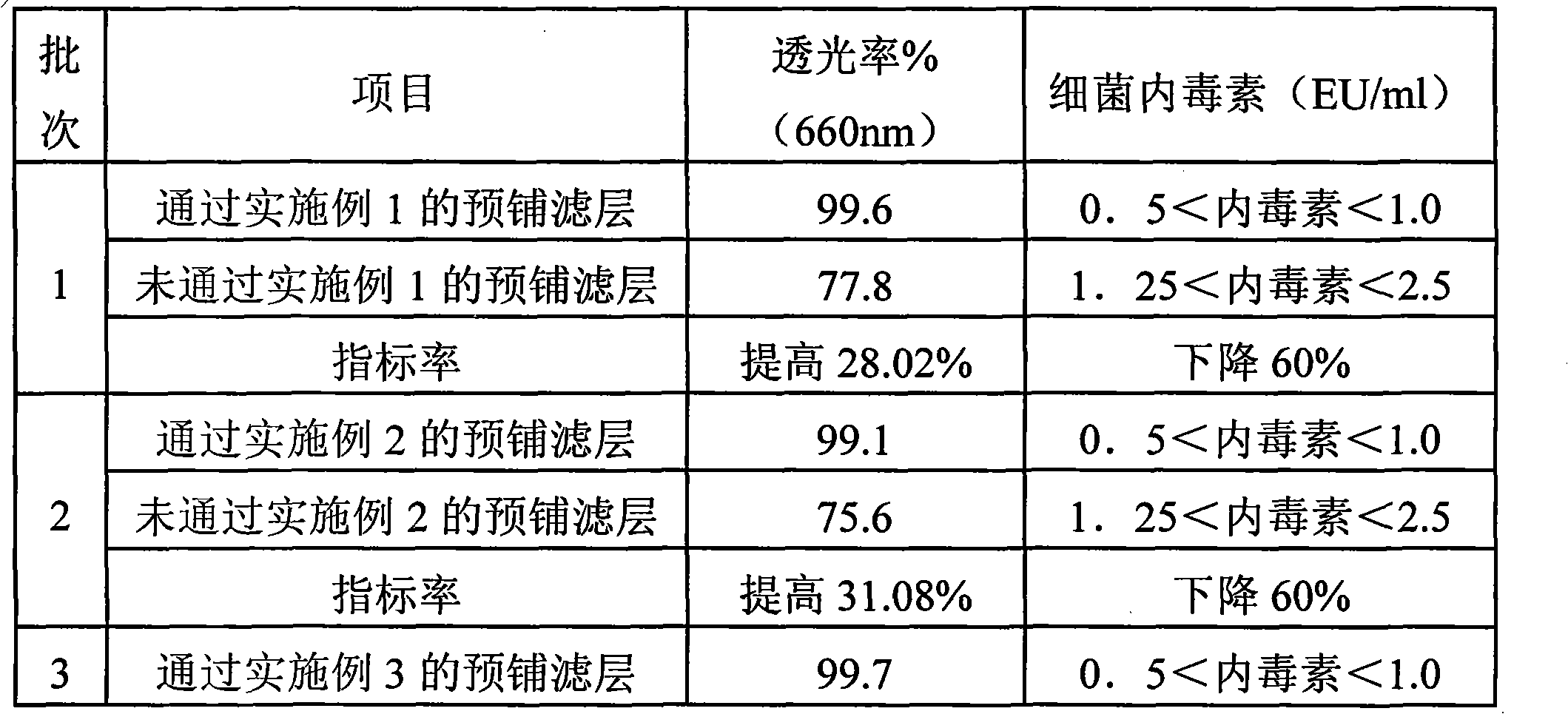

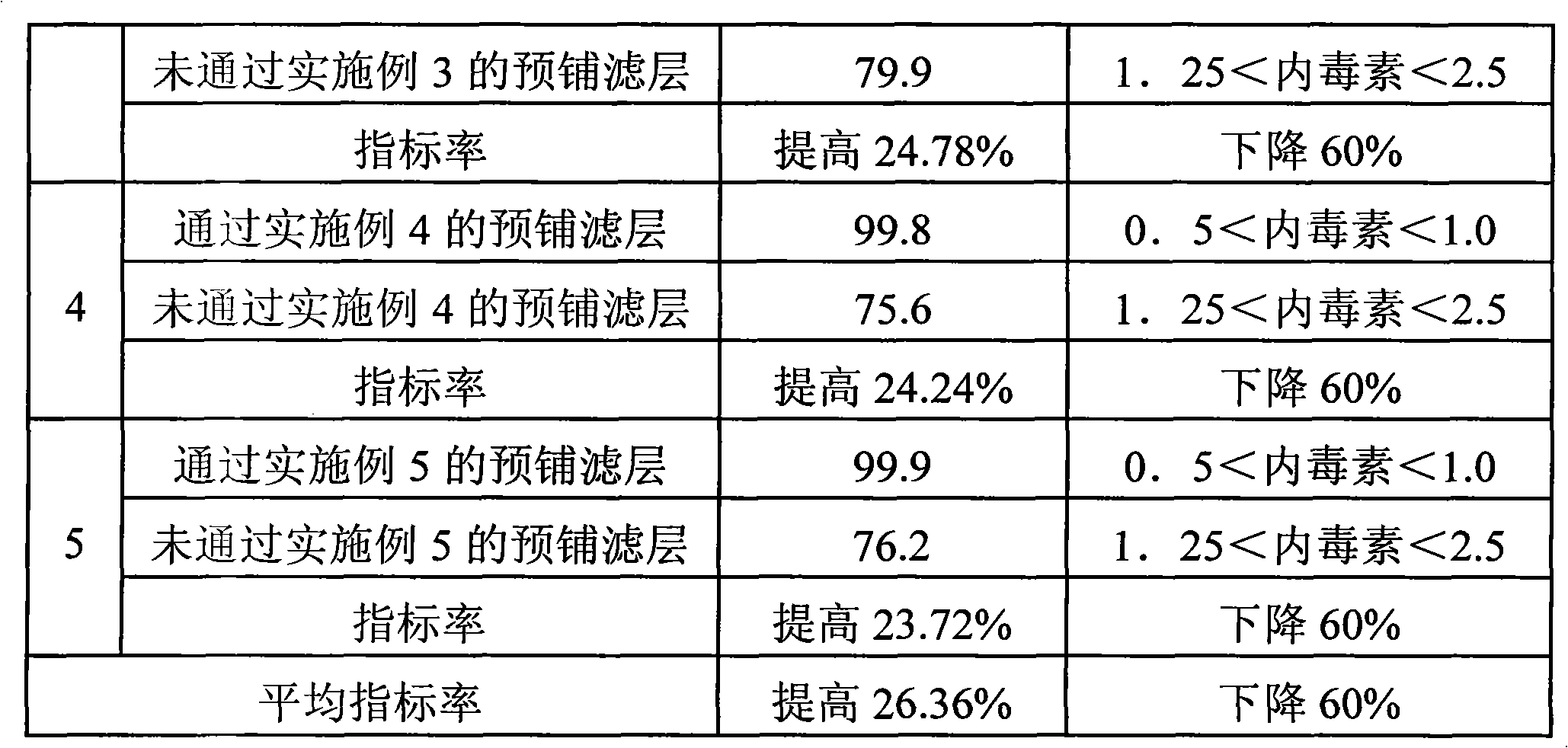

Embodiment 1

[0037] Prepare sodium hyaluronate by the existing extraction method, take 16.5--33 grams of diatomite, add 4L of water to moisten it, and stir evenly to obtain a suspension of diatomite. The electric mixer produced by Shanghai Meiyingpu is used for stirring, and the stirring paddle is in the form of propulsion.

[0038] In the stirring state, use the peristaltic pump (model WL600B-YZ1515 / 2.4) produced by Changzhou Purui Fluid to circulate and filter the suspension of diatomite and pre-spread it on the titanium rod of the titanium rod filter, so that the diatomite is in the A pre-laid filter layer is pre-laid on the titanium rod, and the thickness of the pre-laid filter layer is 2-4 mm.

[0039] The specific process of recirculating filtration and pre-spreading on the titanium rod of the titanium rod filter is: after the diatomite is wetted with purified water, the above-mentioned mixer is used to stir continuously to avoid the diatomite from settling to obtain a suspension of ...

Embodiment 2

[0042] Prepare sodium hyaluronate by the existing extraction method, take 41--58 grams of diatomite, add 4L of water to moisten it, and stir evenly to obtain a suspension of diatomite. In the state of stirring, use a pump to pre-spread the wetted diatomite circulation filter on the titanium rod, so that the thickness of the diatomite pre-spread on the titanium rod is 5-7 mm. The mixer and pump used are the same as in Example 1. The concrete process of circulation filtration is also with embodiment 1.

[0043]Then use purified water or water for injection to wash the pre-laminated filter layer circularly for 2-5 times. Take 1500 ml of enzymolysis solution, add 7.5 grams of activated carbon to absorb for 30 minutes, then pass the enzymolysis solution through the pre-laid filter layer with positive or negative pressure for decarbonization and filtration. After the decarburized and filtered medicinal solution is subjected to cetylpyridinium chloride CPC complex precipitation, it ...

Embodiment 3

[0045] Prepare sodium hyaluronate by the existing extraction method, take 66-82.5 grams of diatomite, add 4L of water to moisten it, and stir evenly to obtain a suspension of diatomite. In the stirring state, use a pump to pre-spread the wetted diatomite circulation filter on the titanium rod, so that the thickness of the diatomite pre-spread on the titanium rod is 8-10 mm. The mixer and pump used are the same as in Example 1. The concrete process of circulation filtration is also with embodiment 1.

[0046] Then use purified water or water for injection to wash the pre-laminated filter layer circularly for 2-5 times. Take 1500 ml of enzymolysis solution, add 7.5 grams of activated carbon to absorb for 30 minutes, then pass the enzymolysis solution through the pre-laid filter layer with positive or negative pressure for decarbonization and filtration. After the decarbonized and filtered medicinal solution is subjected to cetylpyridinium chloride CPC complex precipitation, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com