Evaporative condensate pump circulating year-round refrigeration device

An evaporative condensation and evaporative condenser technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of reduced heat exchange efficiency, increased cost, increased space occupation, etc., to save manufacturing costs and equipment. Installation space, high heat exchange efficiency and cooling effect, effect of high heat exchange efficiency and cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

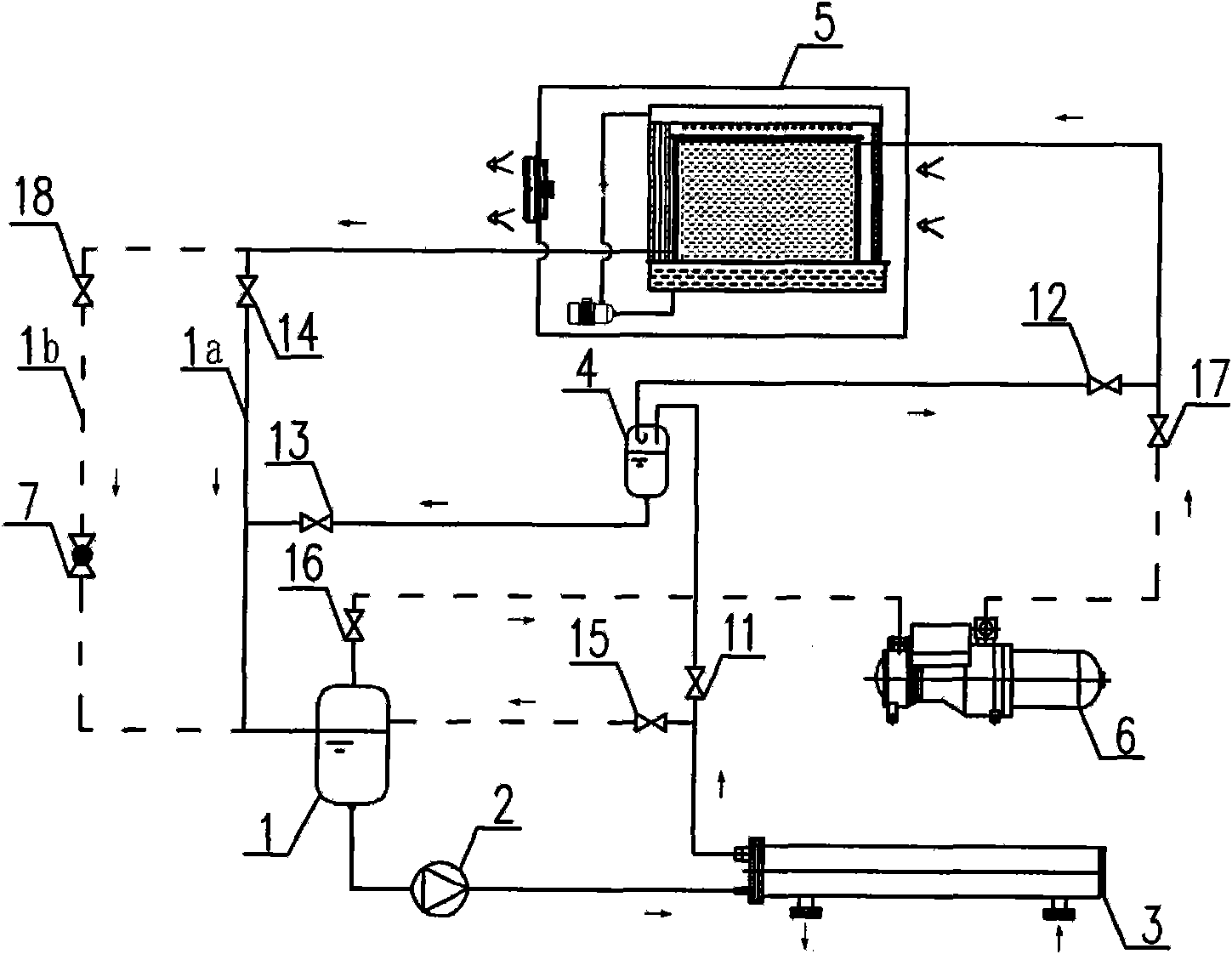

[0032] figure 1It shows a system schematic diagram of an evaporative condensate pump circulation year-round refrigeration device of the present invention, including a circulating liquid storage tank 1, a liquid pump 2, an evaporator 3, an evaporative condenser 5, a compressor 6, a throttling Device 7, the first low-pressure gas valve 15, the second low-pressure gas valve 16, the high-pressure gas valve 17, the fourth liquid pump refrigeration valve 14, the high-pressure liquid valve 18; The outlet of the bottom is connected, the outlet of the liquid pump 2 is connected with the inlet of the evaporator 3; The upper inlet is connected; the inlet of the second low-pressure gas valve 16 is connected with the upper outlet of the circulating liquid storage tank 1, and the outlet of the second low-pressure gas valve 16 is connected with the air inlet of the compressor 6; the high-pressure gas valve 17 The inlet is connected to the exhaust port of the compressor 6, and the outlet of ...

Embodiment 2

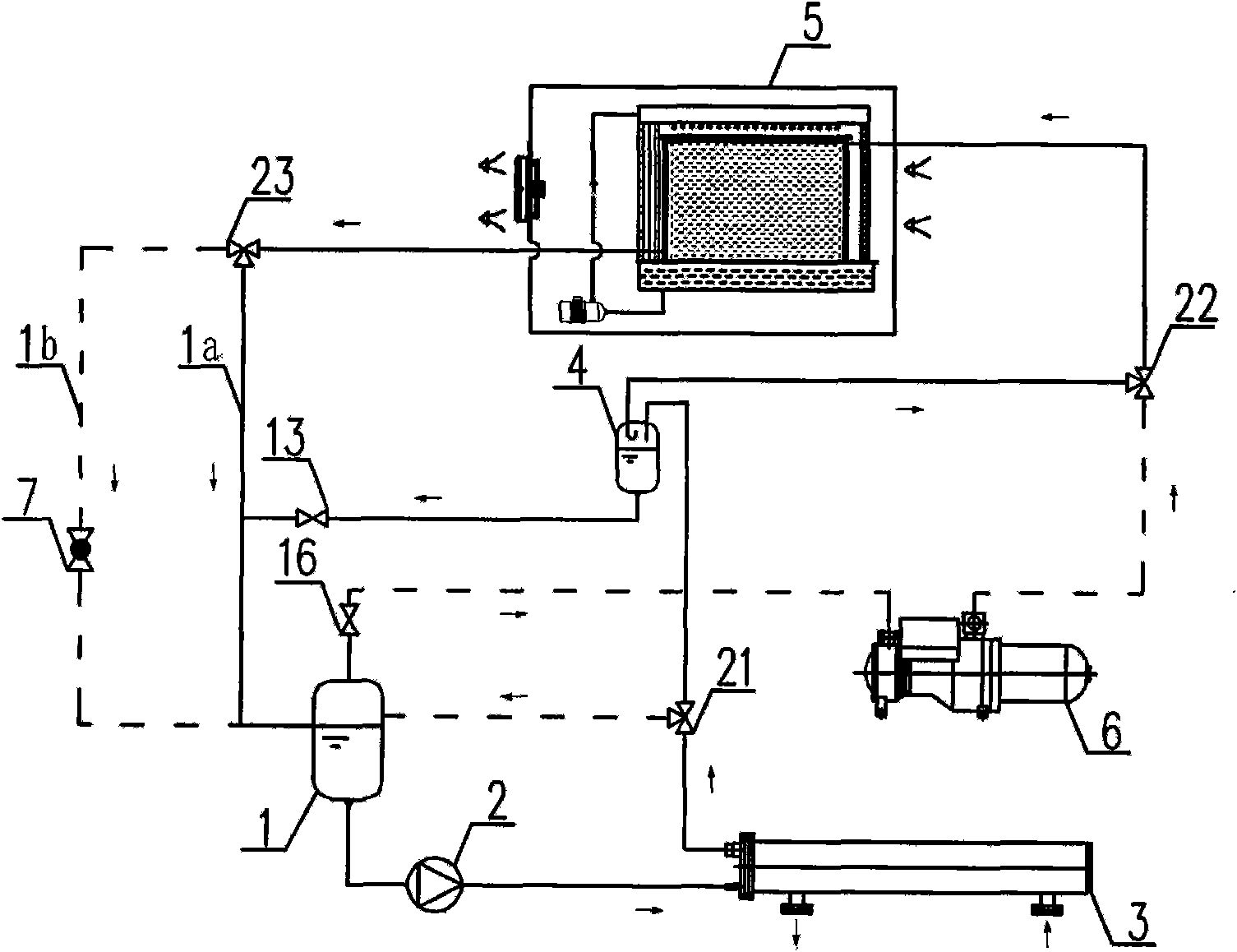

[0039] figure 2 A system schematic diagram of an evaporative condensate pump circulation year-round refrigeration plant using a three-way valve is shown. In this scheme, the first liquid pump refrigeration valve 11 and the first low-pressure gas valve 15 are combined into a first one-in two-out three-way valve 21; the second liquid pump refrigeration valve 12 and the high-pressure gas valve 17 are combined into a two-inlet One outlet three-way valve 22; the fourth liquid pump refrigeration valve 14 and the high-pressure liquid valve 18 are combined into a second one-in two-out three-way valve 23; the inlet of the first one-in two-out three-way valve 21 is connected to the evaporation The outlet of the device 3 is connected, and the two outlets of the first one-in-two-out three-way valve 21 are respectively connected with the upper inlet of the circulating liquid storage barrel 1 and the upper inlet of the gas-liquid separator 4; the two-in and one-out three-way valve 22 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com