High voltage filter and dynamic reactive power compensation control system combining PPF with TSC and control method thereof

A compensation control and dynamic compensation technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, harmonic reduction devices, etc. The effect of grid terminal voltage and improving reactive power compensation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

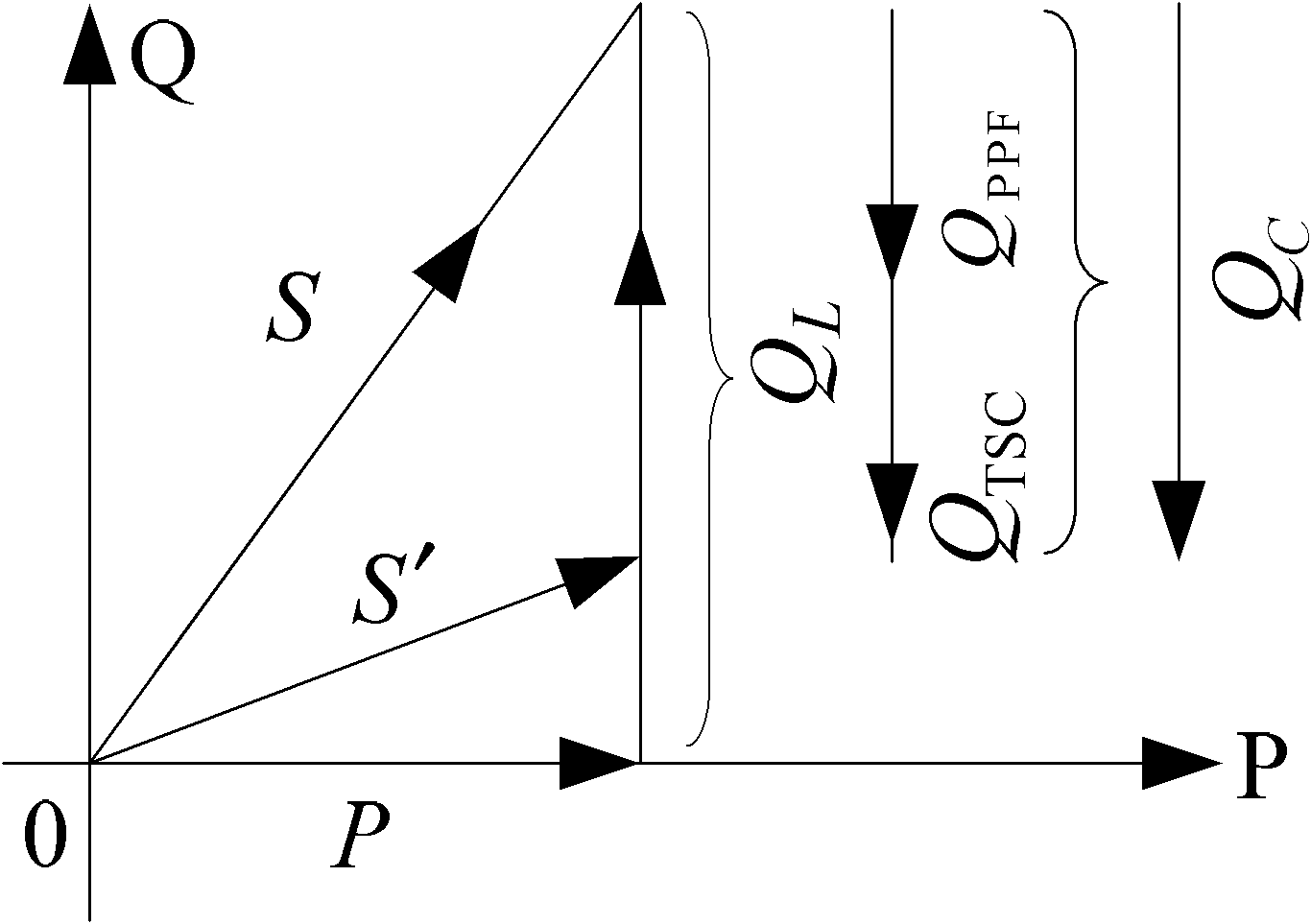

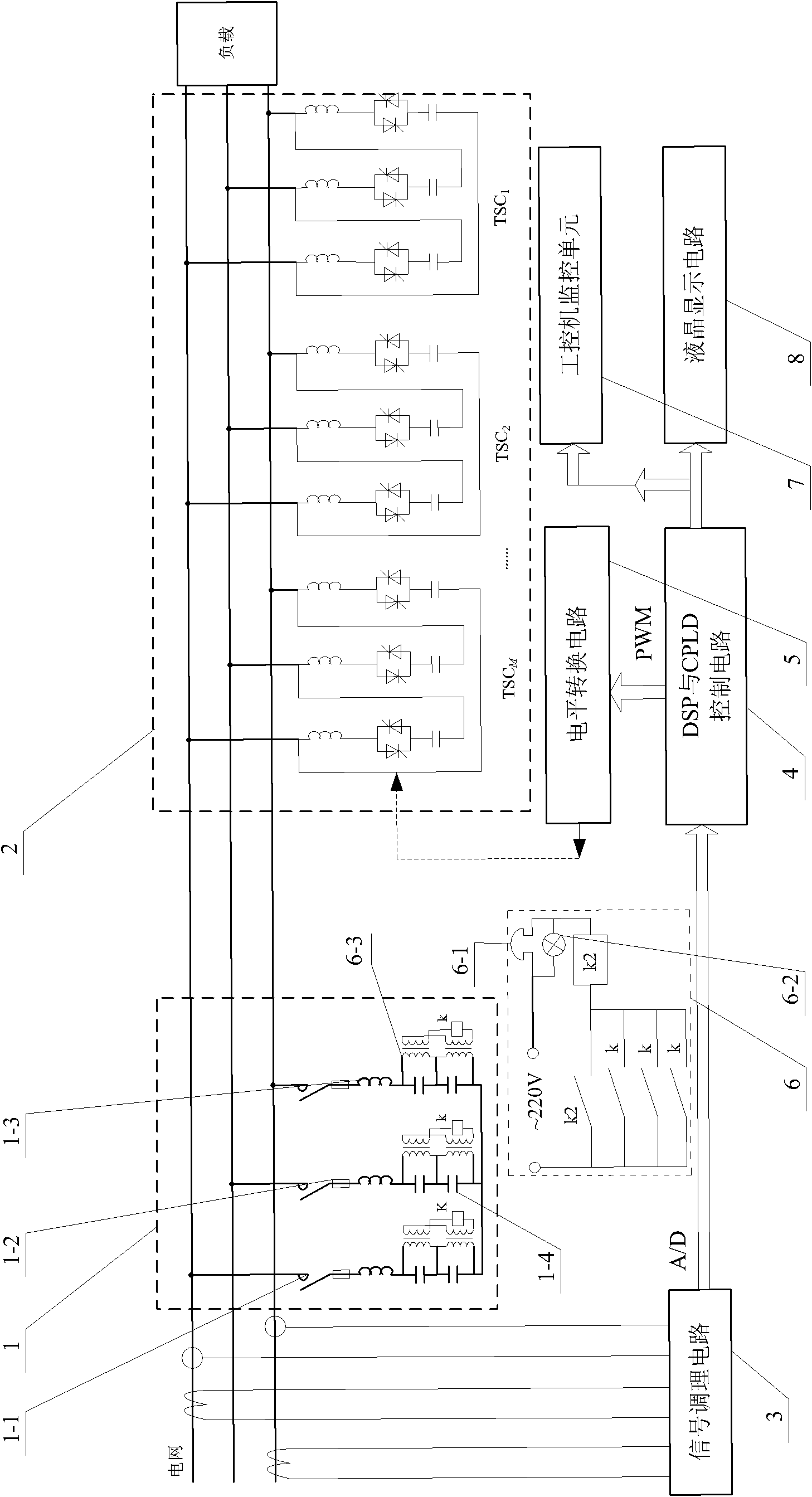

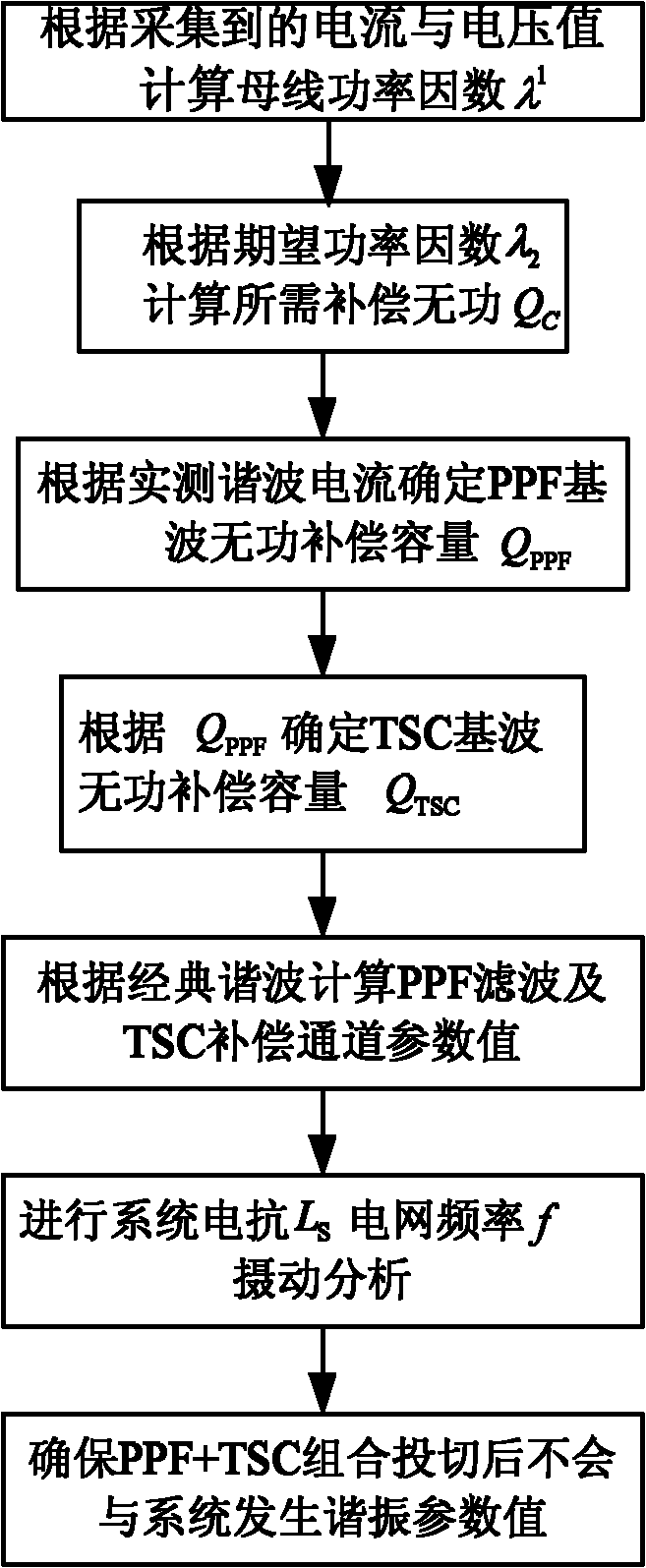

[0026] Specific implementation mode one: the following combination Figure 1 to Figure 2 Describe this embodiment, the high-voltage filtering and dynamic reactive power compensation control system combining PPF and TSC described in this embodiment includes a passive filter unit 1, a reactive power dynamic compensation unit 2, a signal conditioning circuit 3, and a DSP and CPLD control circuit 4 and level shifting circuit 5,

[0027] The passive filtering unit 1 and the reactive power dynamic compensation unit 2 are connected in parallel between the grid input terminal and the load terminal, and the signal conditioning circuit 3 is used to detect the three-phase current signal and the three-phase voltage signal at the input terminal of the grid, and the voltage of the signal conditioning circuit 3 The voltage and current signal input terminals of the DSP and the CPLD control circuit 4 are connected to the current signal output terminal, the PWM control signal output terminal of...

specific Embodiment approach 2

[0028] Specific implementation mode two: the following combination figure 2 Describe this embodiment. This embodiment is a further description of Embodiment 1. The passive filter unit 1 is composed of three star branches, and the three star branches are connected in star form. Each star branch is routed by a circuit breaker 1 -1, fuse 1-2, filter reactor 1-3 and two filter capacitors 1-4,

[0029] A circuit breaker 1-1, a fuse 1-2, a filter reactor 1-3 and two filter capacitors 1-4 in each star branch are connected in series in sequence. Other components and connections are the same as those in Embodiment 1.

specific Embodiment approach 3

[0030] Specific implementation mode three: the following combination figure 2 This embodiment is described. This embodiment is a further description of Embodiment 1. The reactive power dynamic compensation unit 2 is composed of M groups of thyristor switching capacitors TSC, and the compensation capacity of M groups of thyristor switching capacitors TSC is according to 2 n-1 Coding method grouping, n=1, 2, ..., N, where M is an integer greater than 1, N≤M, M groups of thyristor switching capacitors TSC are connected to the power grid in parallel,

[0031] Each group of thyristor switching capacitors TSC is composed of three angular branches connected in an angular shape, and each angular branch is composed of an inductance coil, two anti-parallel thyristors and capacitors in series. Other components and connections are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com