Brake system

A brake system and brake technology, which is applied in the direction of brakes, etc., can solve the problems of increasing the air consumption of the auxiliary accumulator, increasing the air consumption, and increasing the air consumption of the braking system, so as to reduce the total air consumption and reduce the Inflation time, effect of reducing brake release time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

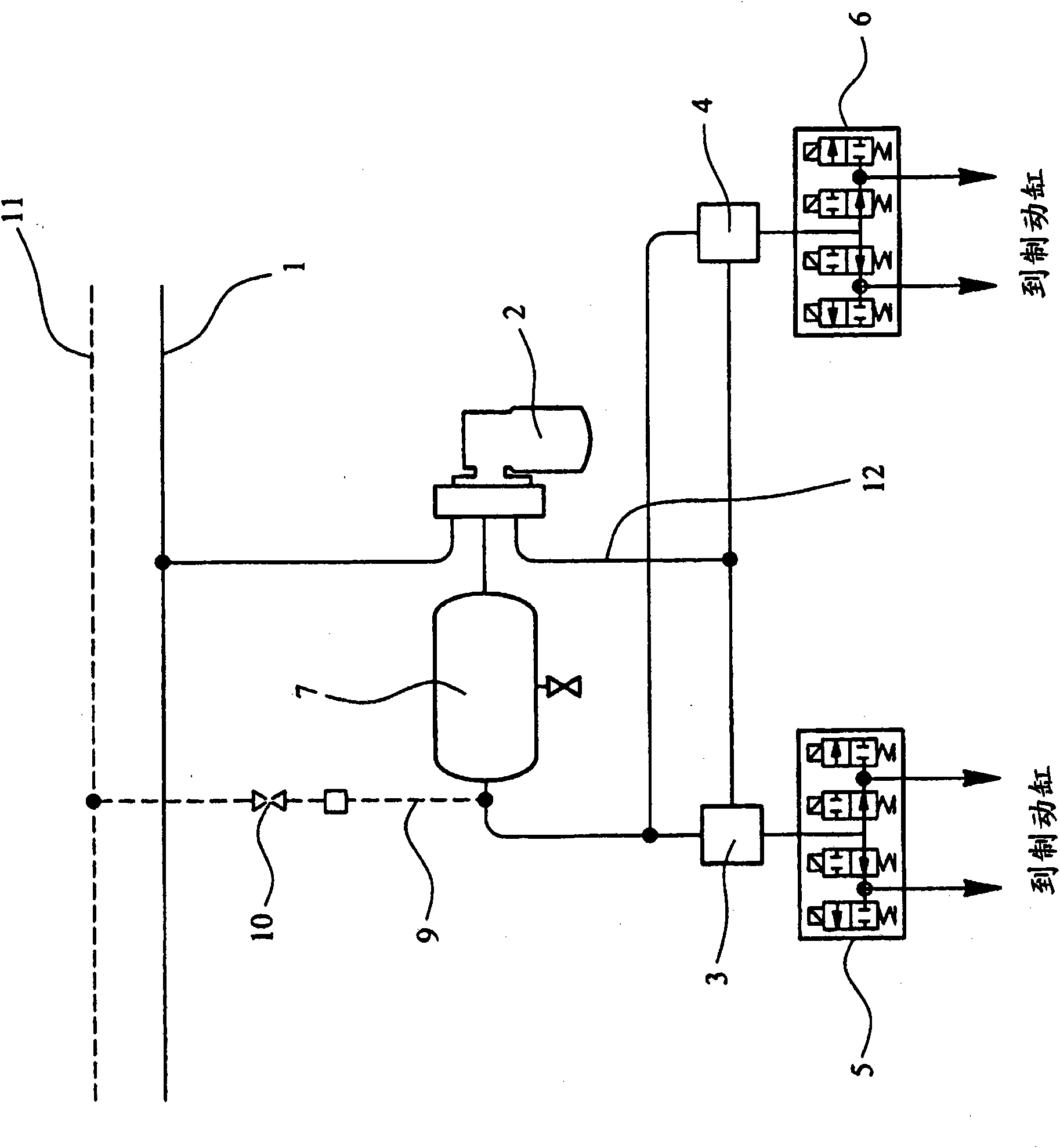

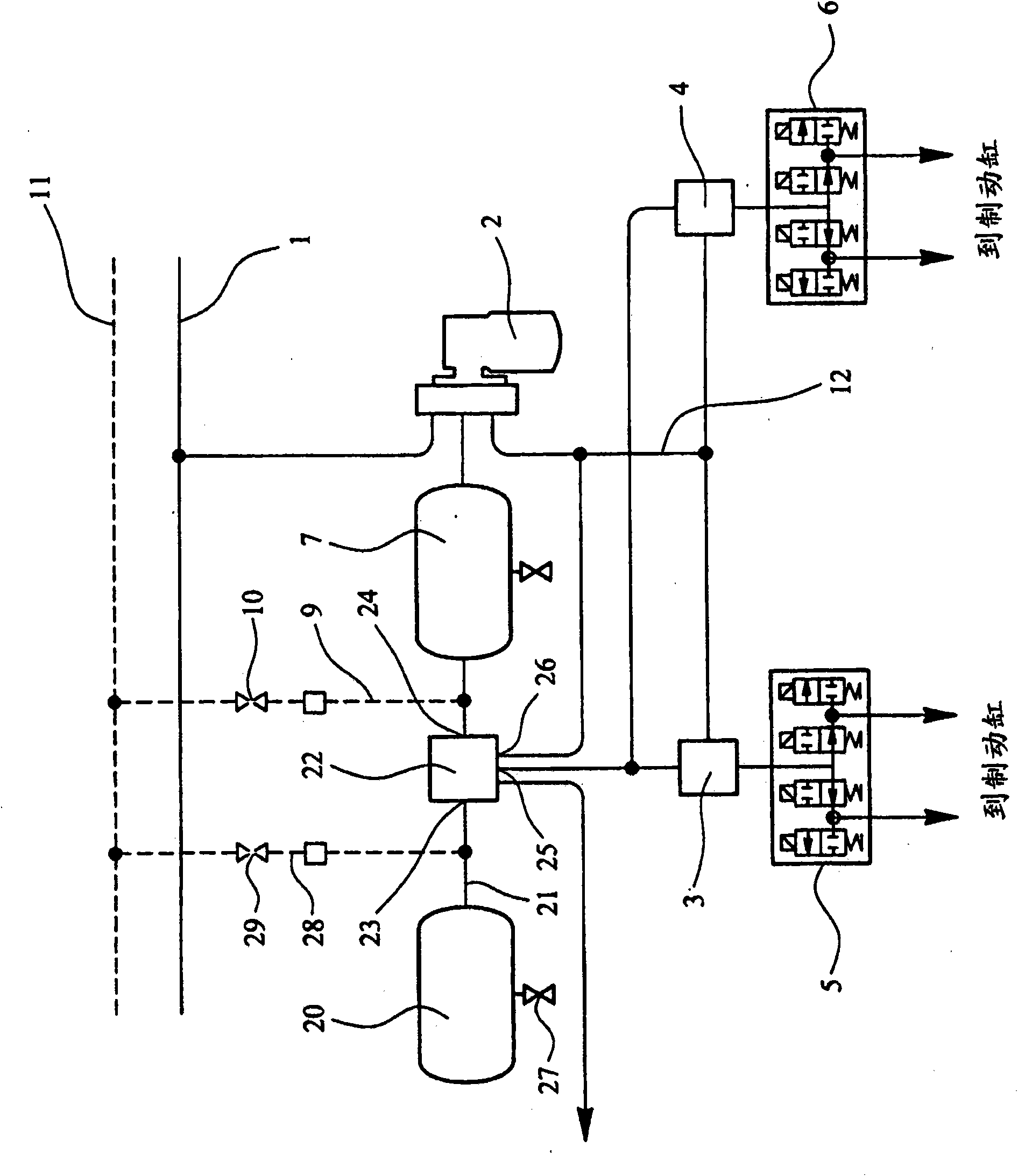

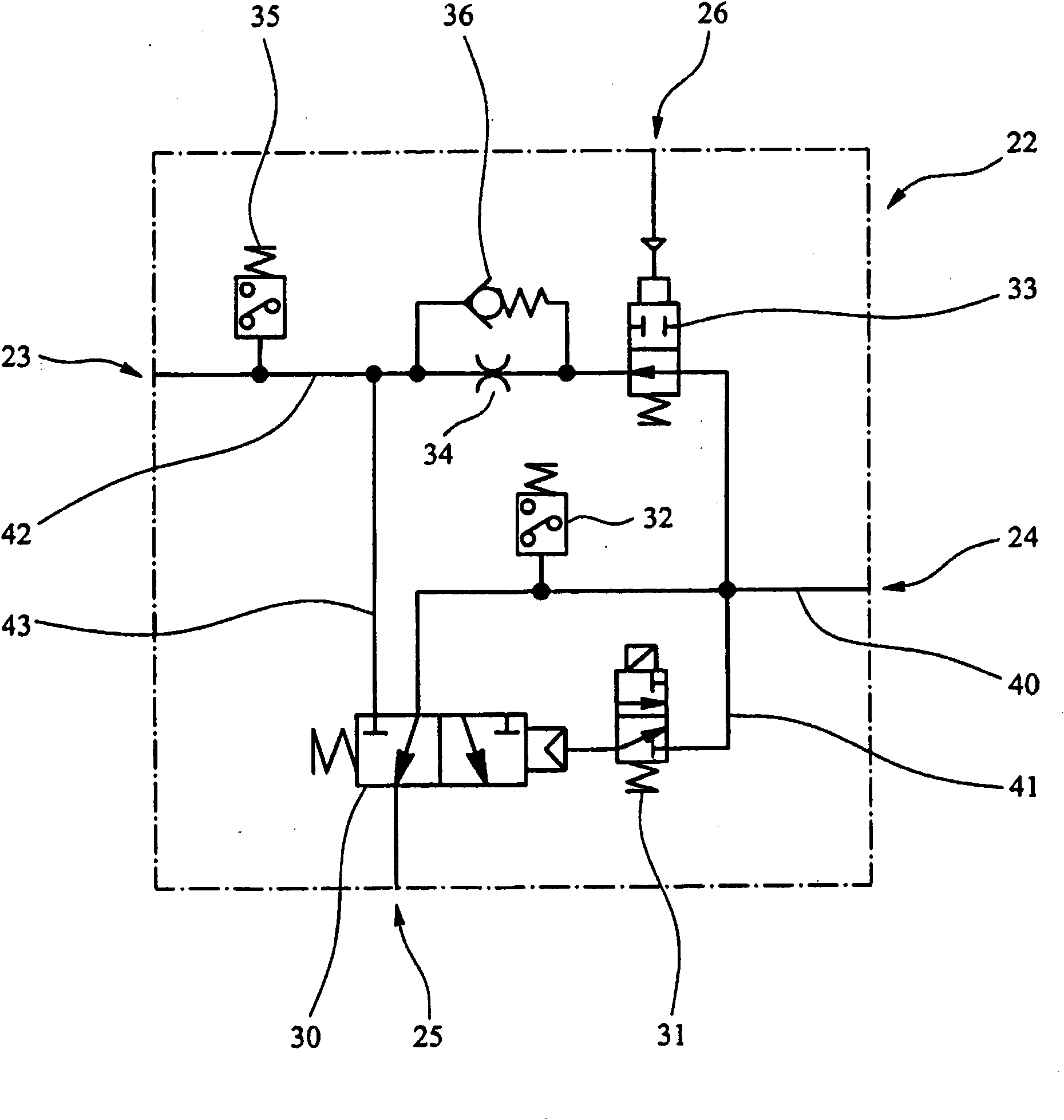

[0022] figure 1 A schematic diagram showing a part of a known arrangement for a rail brake system comprising a main brake pipe 1 in fluid communication with a brake distributor 2 which is fluidly connected via a line 12 to relay valves 3, 4 which are each connected to a respective relief valve 5, 6 which is connected to a respective brake cylinder (not shown ). The brake distributor 2 has virtual cylinder pressure and will usually have integrated relay valve capability. Typically, there will be one relay valve and one dump valve per bogie, or one dump valve per axle. It is also known to use variable load valves instead of the relay valves 3 , 4 .

[0023] An auxiliary accumulator 7 is provided which remains in fluid communication with the brake distributor 2 via a first outlet and is also in fluid communication with each of the relay valves 3 , 4 via a second outlet. The auxiliary accumulator pressure is protected by a check valve in distributor 2. The solid lines show th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com