Retardation film

A retardation film and light scattering technology, which is applied in the direction of instruments, optics, optical components, etc., can solve the problems of poor transmittance, poor image ratio of liquid crystal display, etc., and achieve the effect of excellent frontal contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

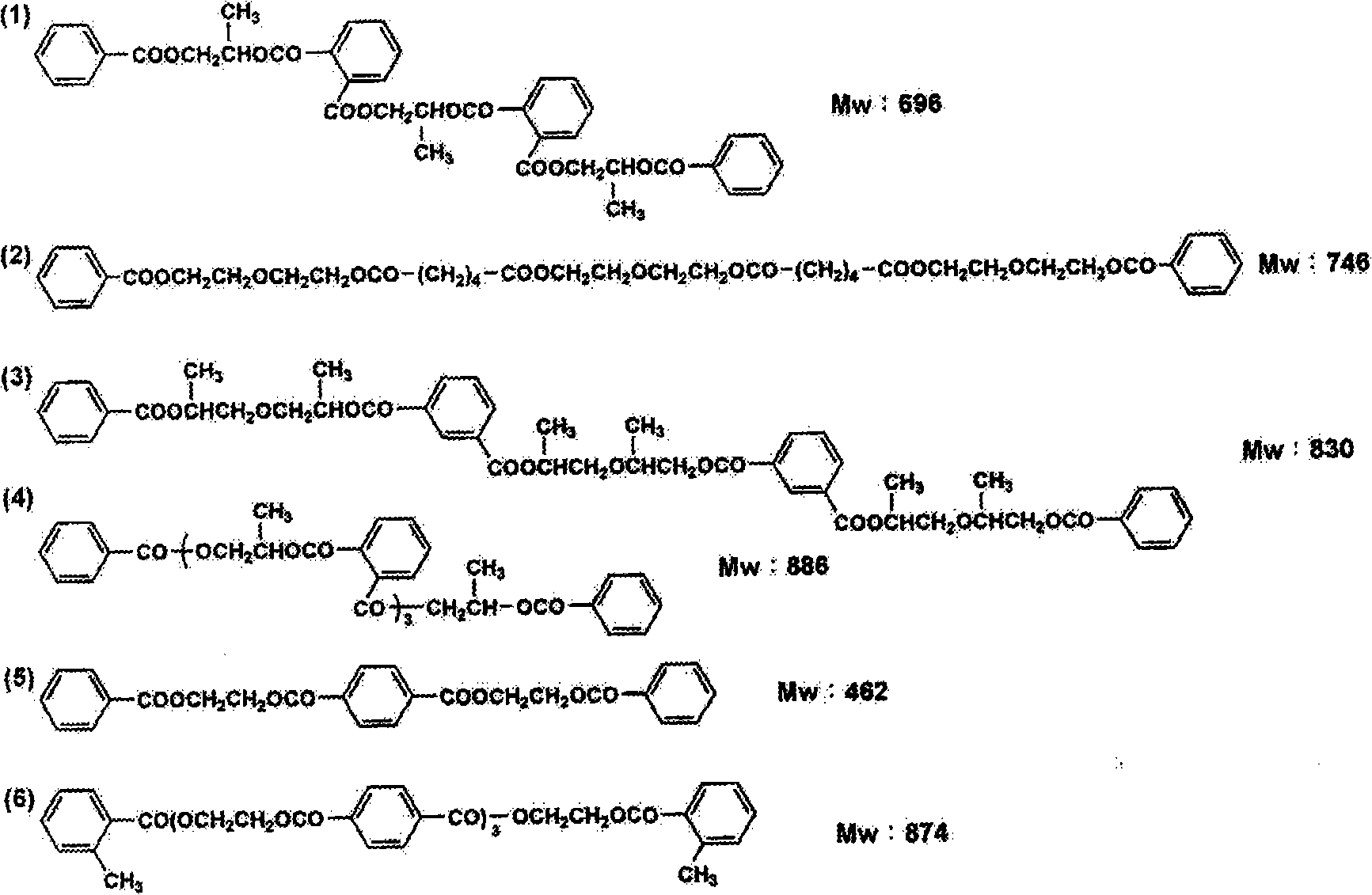

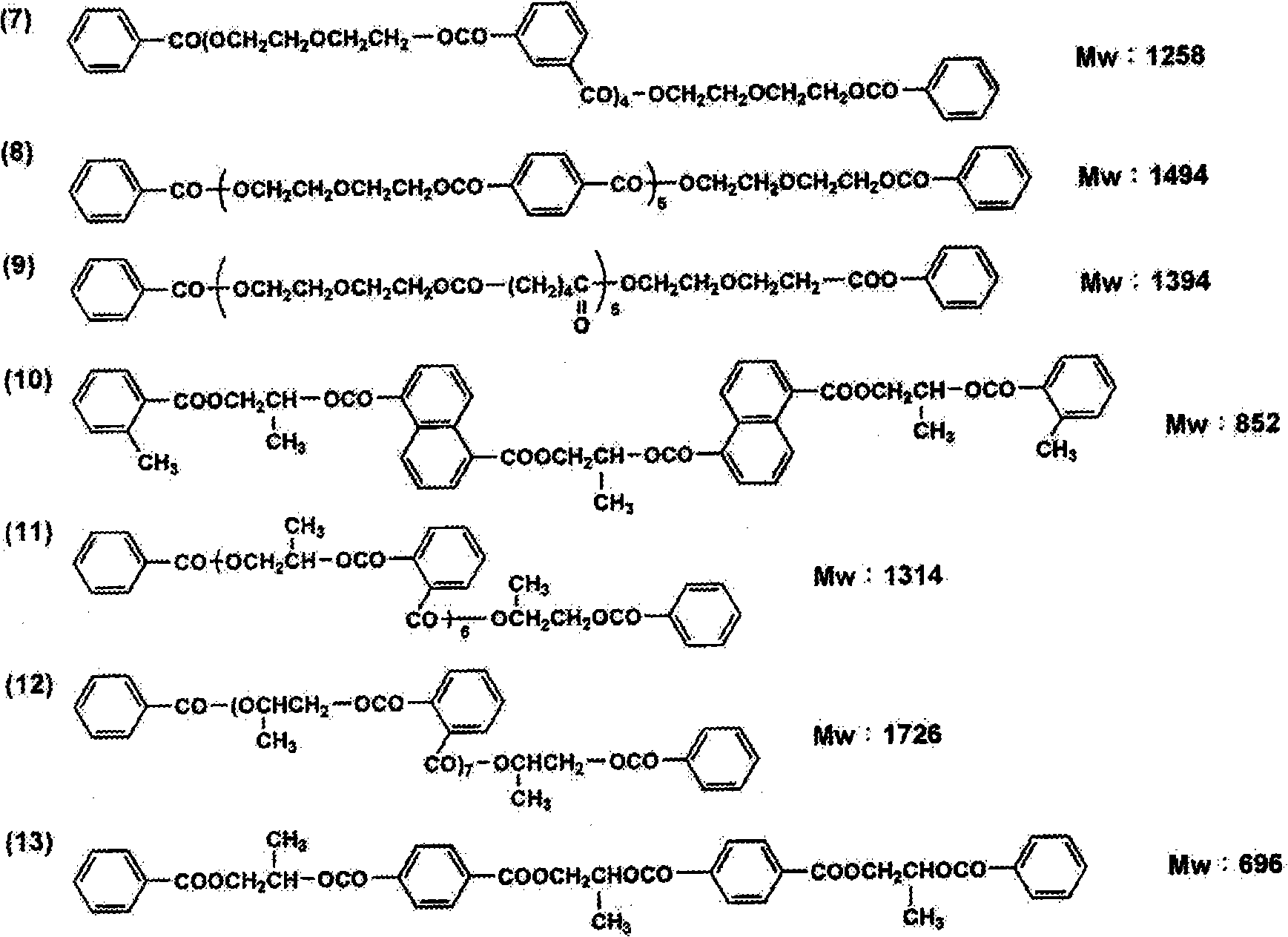

Method used

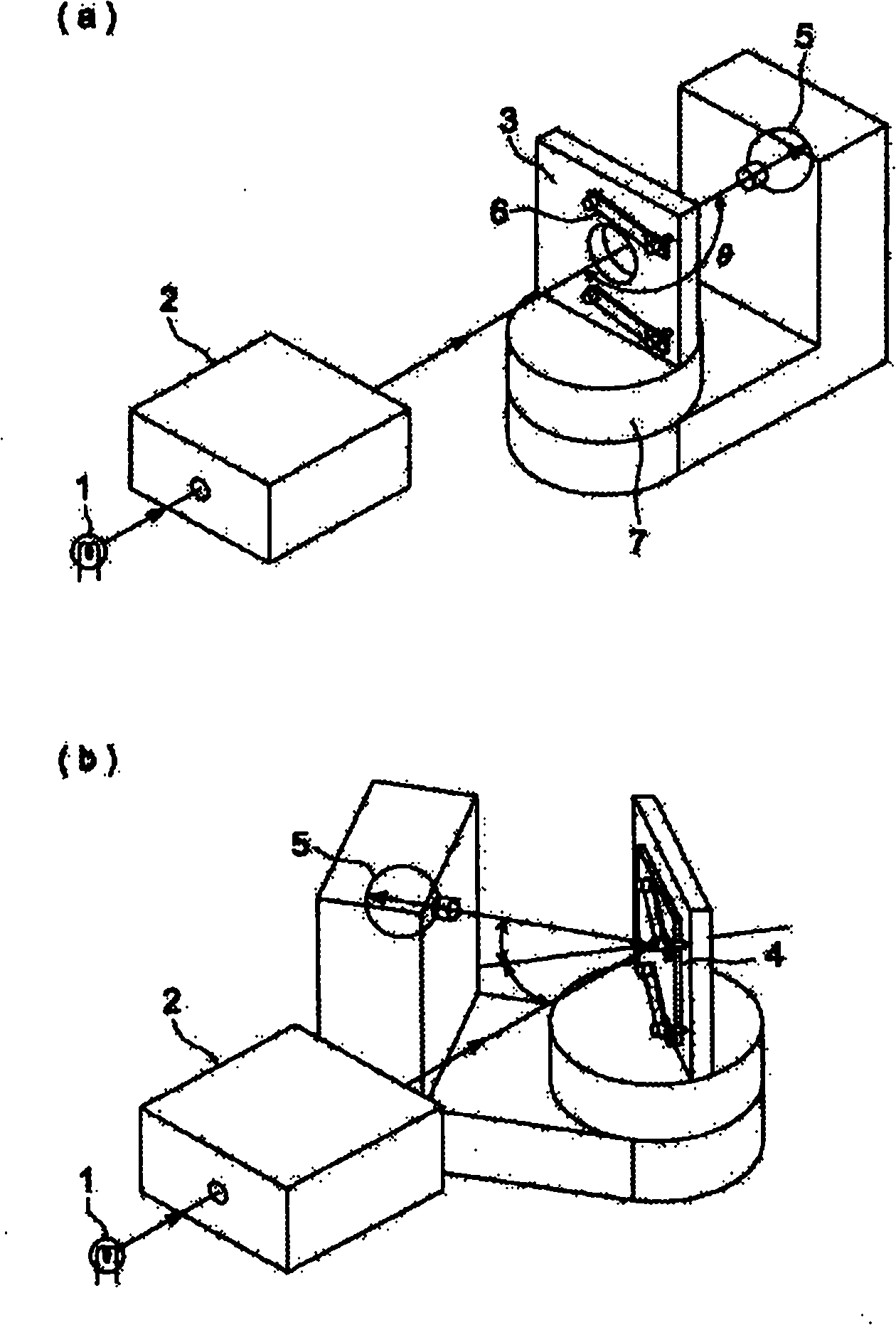

Image

Examples

Embodiment 1

[0320]

[0321]

[0322] Particles (AEROSIL R972V Nippon Aerosil Co., Ltd.) 11 parts by mass

[0323] 89 parts by mass of ethanol

[0324] After stirring and mixing the above components for 50 minutes with a dissolver, it was dispersed with a Manton-Golin.

[0325]

[0326] While fully stirring, the fine particle dispersion 1 was slowly added to the dissolution tank filled with methylene chloride. Then, dispersion is performed using an attritor mill so that the particle size of the secondary particles becomes a specified size. This dispersion liquid was filtered using Finemet NF manufactured by Nippon Seisen Co., Ltd., to prepare a fine particle addition liquid 1.

[0327] Dichloromethane 99 parts by mass

[0328] Particle dispersion 15 parts by mass

[0329] The main glue liquid of the following composition was prepared. First, add dichloromethane and ethanol to a pressurized dissolution tank. While stirring, the cellulose esters A and B were charged into a pressu...

Embodiment 2

[0360]

[0361] A polyvinyl alcohol film having a thickness of 120 μm was uniaxially stretched (at a temperature of 110° C. and a stretching ratio of 5 times).

[0362] The film was dipped in an aqueous solution consisting of 0.075 g of iodine, 5 g of potassium iodide, and 100 g of water for 60 seconds, and then immersed in a 68° C. aqueous solution of 6 g of potassium iodide, 7.5 g of boric acid, and 100 g of water. This was washed with water, followed by drying to obtain a polarizer.

[0363] Then, according to the following steps 1 to 5, the polarizer was attached to the above-mentioned cellulose ester films 101 to 207, and KONICA MINOTA TAC KC4UY (a cellulose ester film manufactured by KONICA MINOLTA OPTO Co., Ltd.) was attached to the back side. ), thus making a polarizer.

[0364] Step 1: After immersing in a 2 mol / L sodium hydroxide solution at 60°C for 90 seconds, washing with water, followed by drying to obtain saponified cellulose ester on the side to be attached ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com