System and method for removing disulfide from regeneration exhaust gas of caustic fluid used in liquid gas sweetening process

A disulfide and liquefied gas technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as equipment dew point corrosion, stench, and serious environmental pollution, and achieve no power consumption and high desulfurization efficiency , The effect of low exhaust gas treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

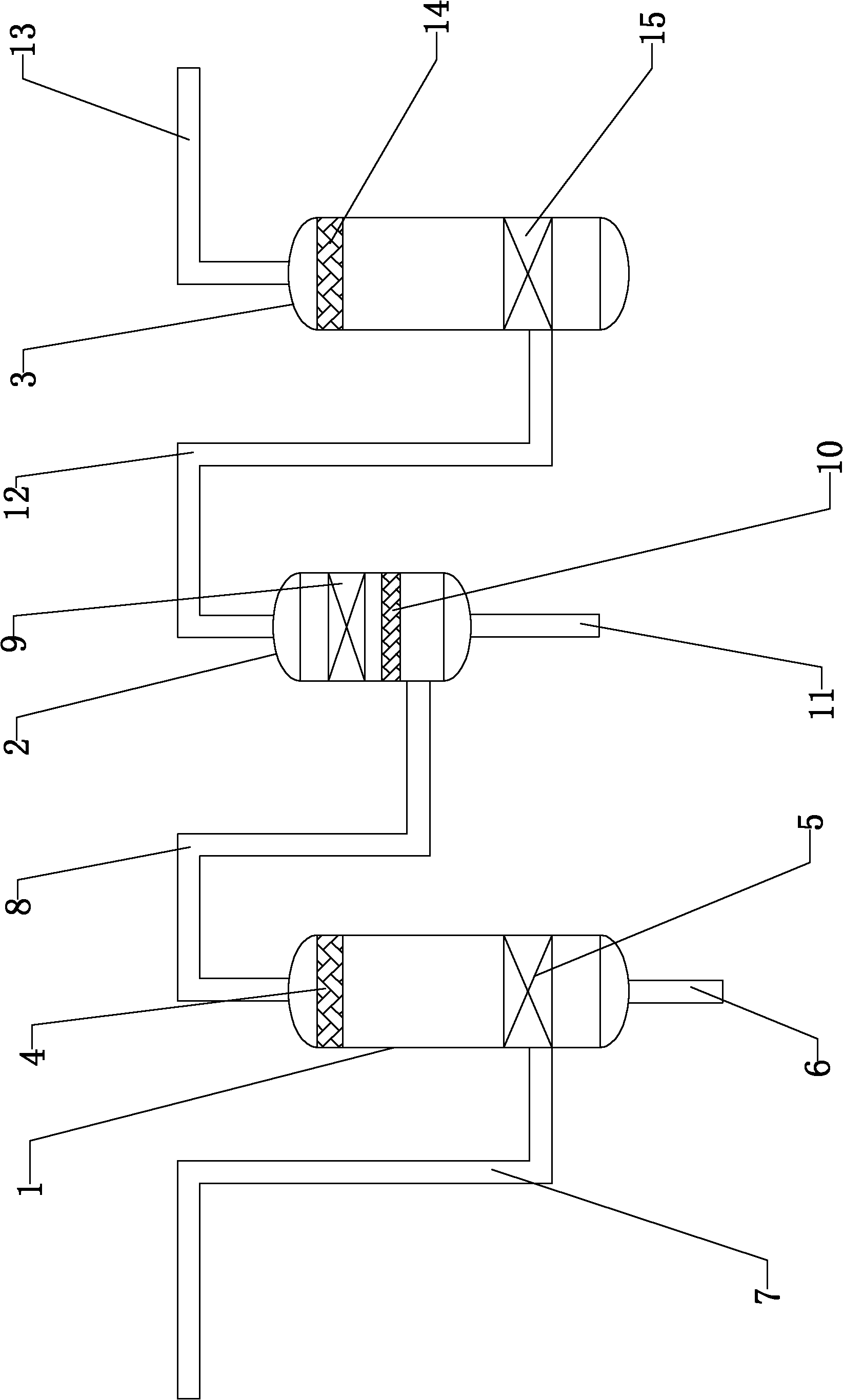

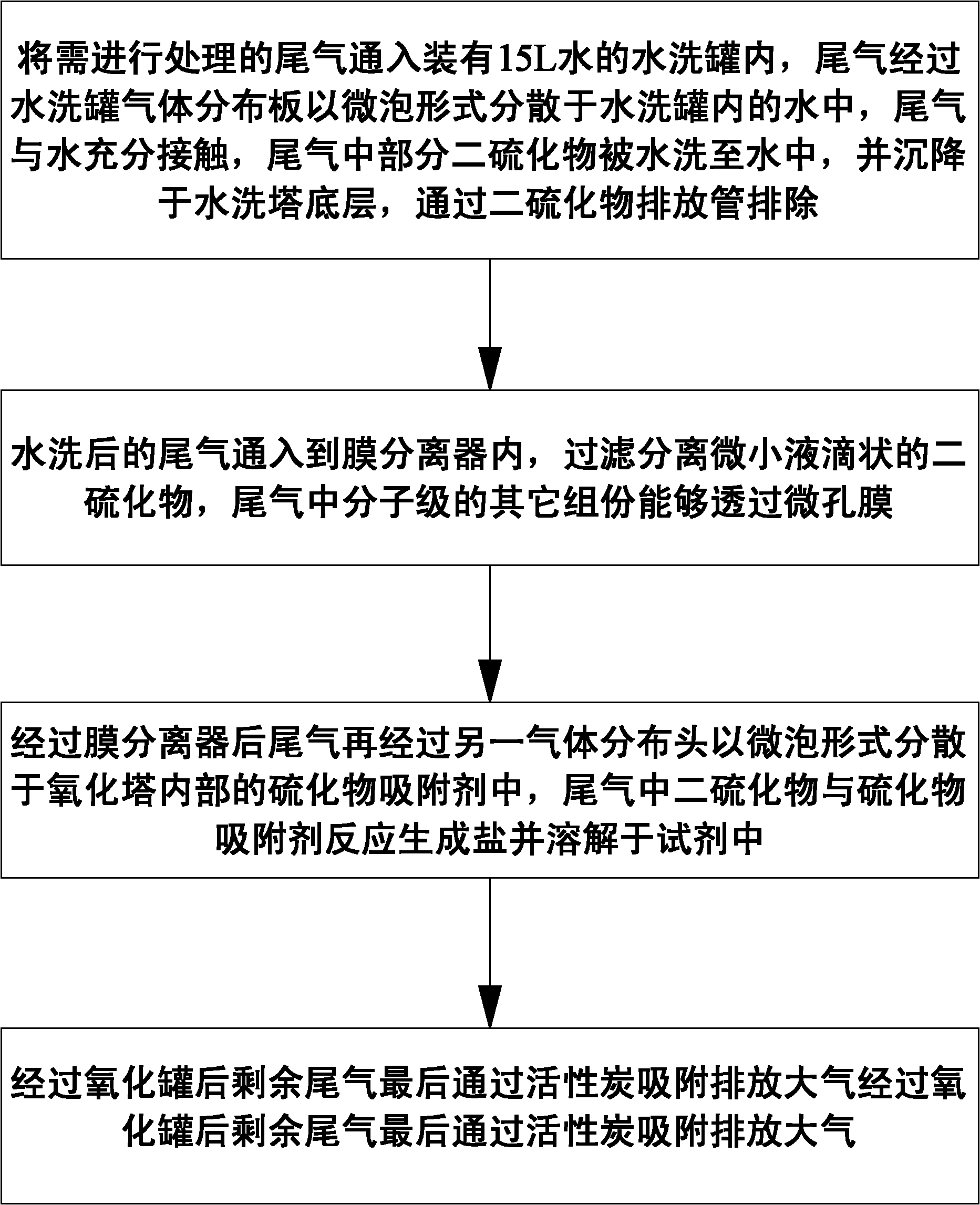

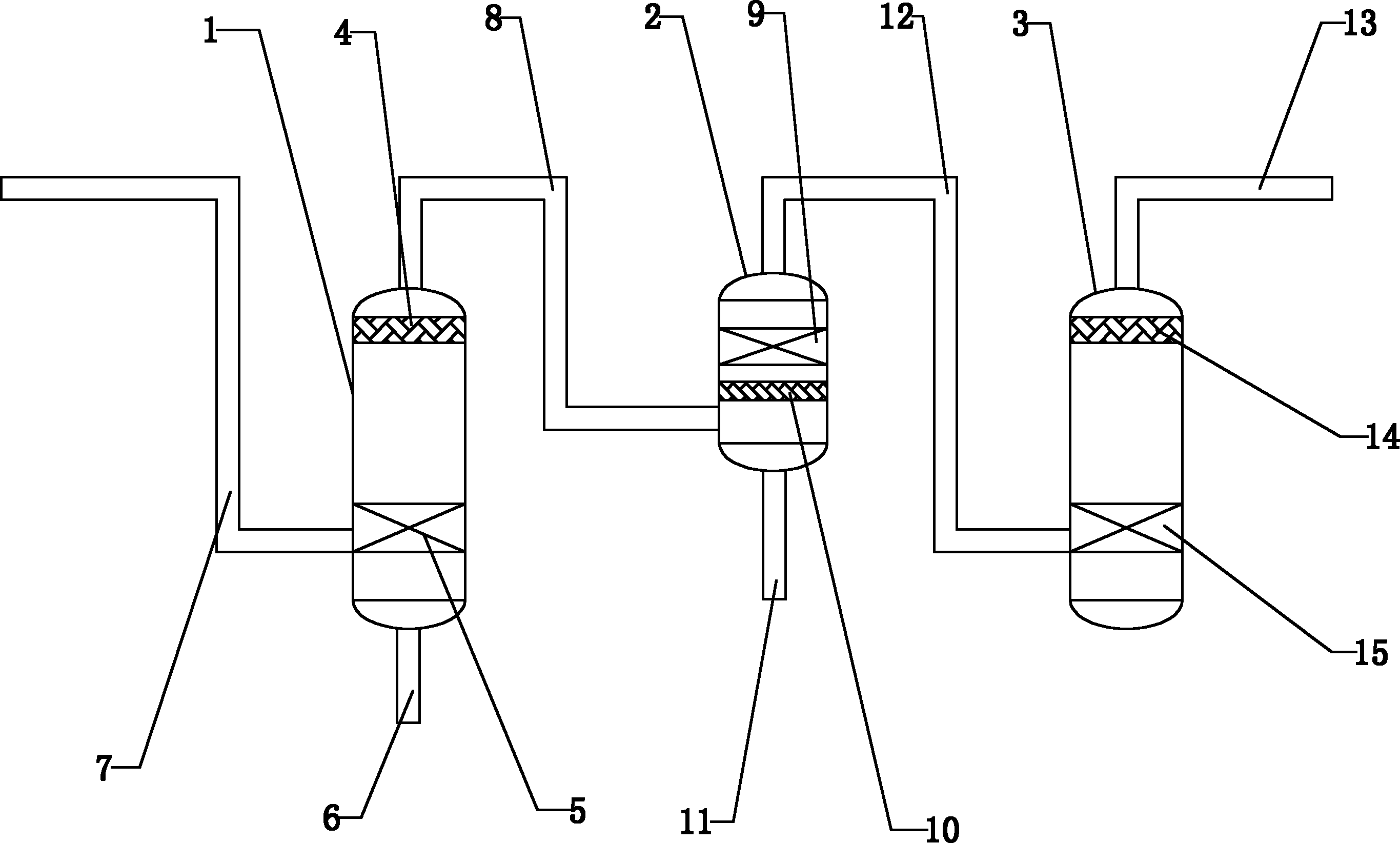

[0010] like Figure 1-2 As shown, a liquefied gas demercaptan alkali liquor oxidation regeneration tail gas dedisulfide system described in the embodiment of the present invention includes a water washing tank 1, a membrane separator 2 and an oxidation tank 3, the top of the inner wall of the water washing tank 1 and the The bottom of the washing tank is equipped with a demister 4 and a gas distribution plate 5 of the washing tank fixed by bolts. The bottom of the washing tank 1 is connected to the disulfide discharge pipe 6. The corresponding place is provided with an exhaust gas input pipe 7, and the exhaust gas input pipe 7 is connected to the gas distribution plate 5 of the washing tank through a flange. The top of the washing tank 1 is connected to one end of the gas discharge pipe 8 through a flange, and the other end of the gas discharge pipe 8 One end is connected to the bottom of the membrane separator 2 through a flange. The inside of the membrane separator 2 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com