Micro-powder polishing brick

A technology for polishing tiles and micropowders, applied in the field of architectural tiles, can solve the problems of poor tone softness, poor three-dimensional effect and poor texture, and achieve the effects of soft tone, strong three-dimensional effect and good texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] ① Produce the base material according to the conventional process.

[0011] ②The following raw materials are prepared in parts by weight: washed ball soil 12, potassium sodium sand 30, albite feldspar 40, wurstite 10, aluminum sand 8. Grind fineness to 80 mesh or more and sieve 18-20%. Its chemical composition is calculated by weight percentage: SiO 2 67.04, Al 2 o 3 18.25, Fe 2 o 3 0.29, TiO 2 0.2, CaO 1.59, MgO 2.35, K 2 O 2.47, Na 2 O 4.95, IL 2.86.

[0012] ③Using the secondary cloth of the press, the pressure: 30000KN. During the firing process, the surface temperature of the kiln is controlled at 1175°C, the bottom temperature is controlled at 1200°C, and the firing cycle is 55 minutes.

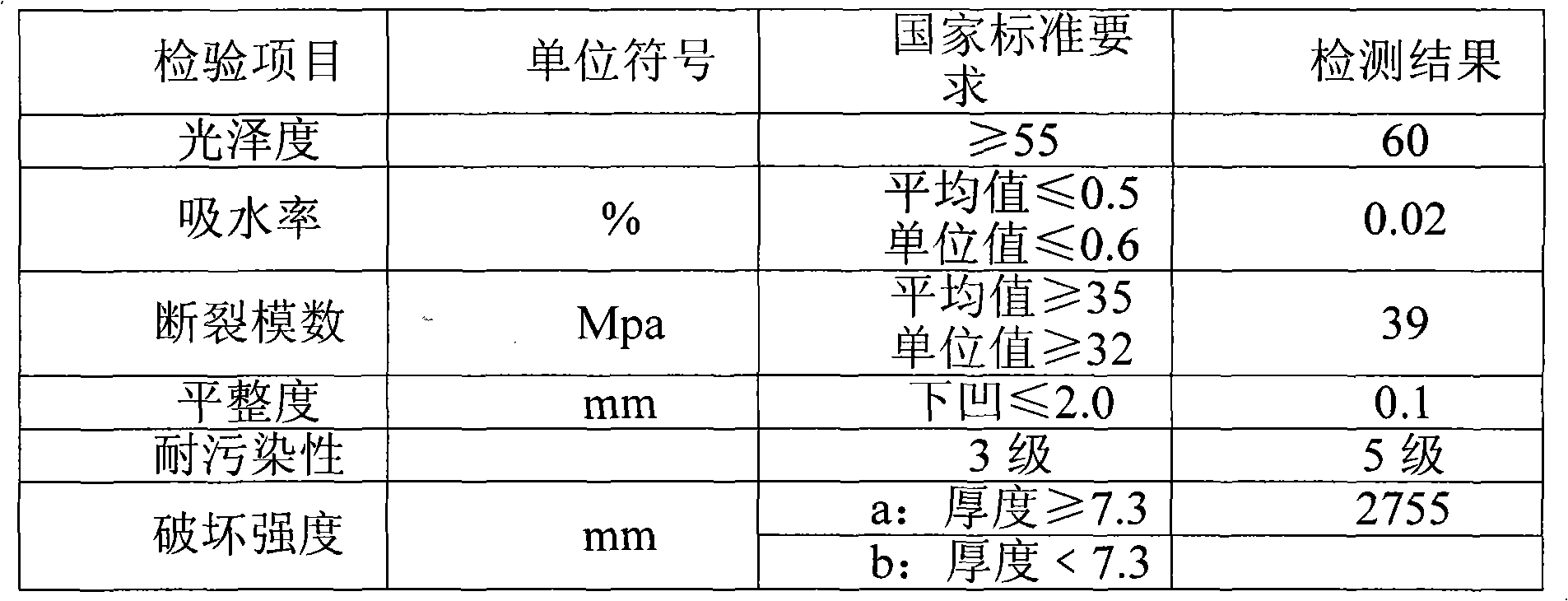

[0013] The detection indexes of the products made in this embodiment are shown in Table 1.

[0014]

[0015] Radioactivity detection: Hebei Provincial Building Sanitary Ceramics Product Quality Supervision and Inspection Station, the inspection results: I(Ra) is...

Embodiment 2

[0017] ① Produce the base material according to the conventional process.

[0018] ②The following raw materials are prepared in parts by weight: washed ball soil 18, potassium sodium sand 24, albite feldspar 40, wurstite 10, aluminum sand 8. Grind fineness to 80 mesh or more and sieve 18-20%. Its chemical composition is SiO in weight percent 2 67.14, Al 2 o 3 18.52, Fe 2 o 3 0.26, TiO 2 0.14, CaO 1.52, MgO 2.45, K 2 O 2.20, Na 2 O 4.68, IL 3.04, and the balance is unanalyzed trace substances.

[0019] ③Using the secondary cloth of the press, the pressure: 31000KN. During the firing process, the surface temperature of the kiln is controlled at 1180°C, the bottom temperature is controlled at 1225°C, and the firing cycle is 45 minutes.

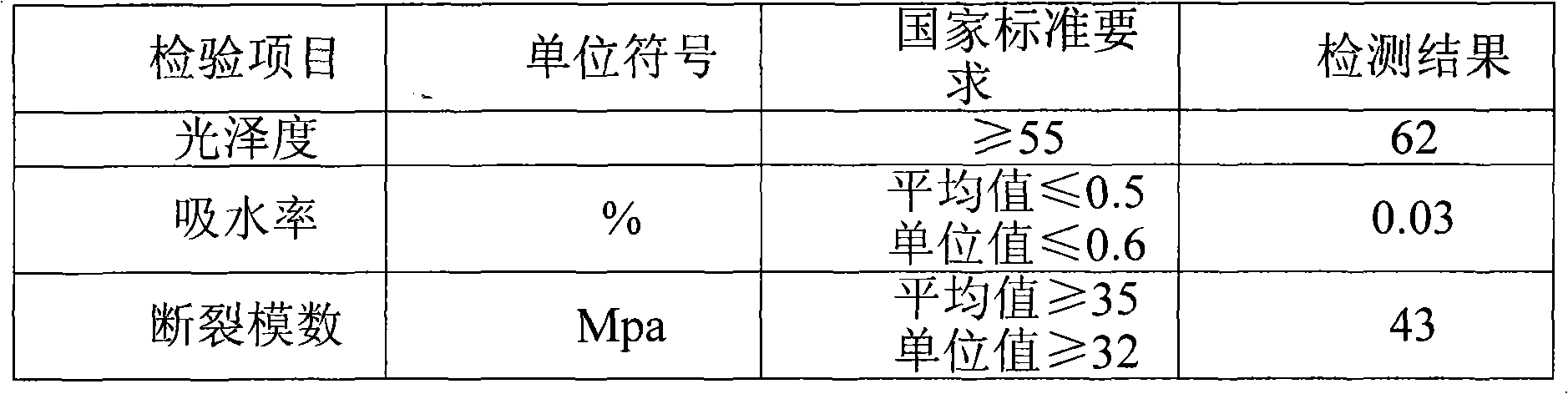

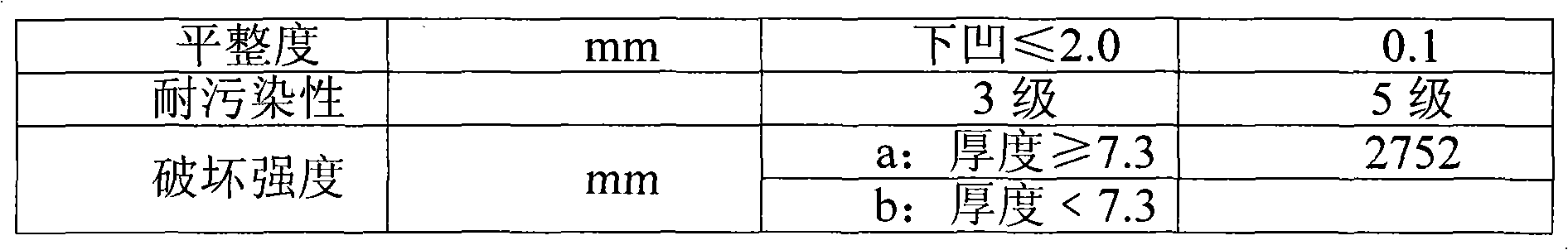

[0020] The detection indexes of the products made in this embodiment are shown in Table 1.

[0021]

[0022]

[0023] Radioactivity detection: Hebei Provincial Building Sanitary Ceramics Product Quality Supervision and Inspec...

Embodiment 3

[0025] ① Produce the base material according to the conventional process.

[0026] ②The following raw materials are prepared in parts by weight: washed ball soil 18, potassium sodium sand 30, albite feldspar 40, wurstite 4, aluminum sand 8. Grind fineness to 80 mesh or more and sieve 18-20%. Its chemical composition is SiO in weight percent 2 66.56, Al 2 o 3 19.75, Fe 2 o 3 0.28, TiO 2 0.16, CaO 0.96, MgO1.21, K 2 O 2.46, Na 2 O 4.94, IL 3.52, and the balance is unanalyzed trace substances.

[0027] ③Using the secondary cloth of the press, the pressure: 32000KN. During the firing process, the surface temperature of the kiln is controlled at 1178°C, the bottom temperature is controlled at 1210°C, and the firing cycle is 50 minutes.

[0028] The detection indexes of the products made in this embodiment are shown in Table 1.

[0029]

[0030] Radioactivity detection: Hebei Provincial Building Sanitary Ceramics Product Quality Supervision and Inspection Station, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com