Method for hydrotreating poor diesel

A technology for hydrotreating and low-quality diesel oil, which is applied in the petroleum industry and refining hydrocarbon oil, etc., and can solve the problems of high investment cost and high operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

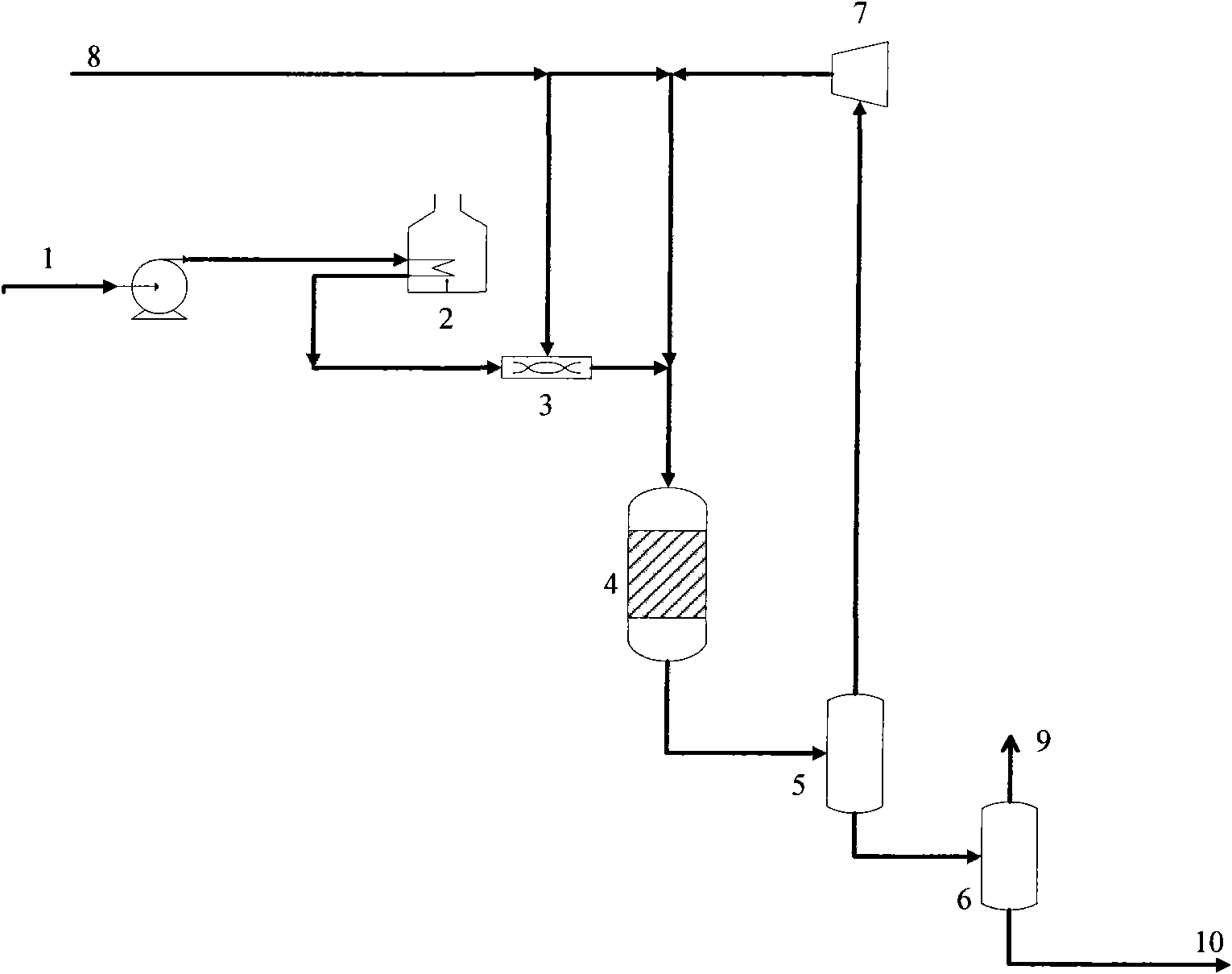

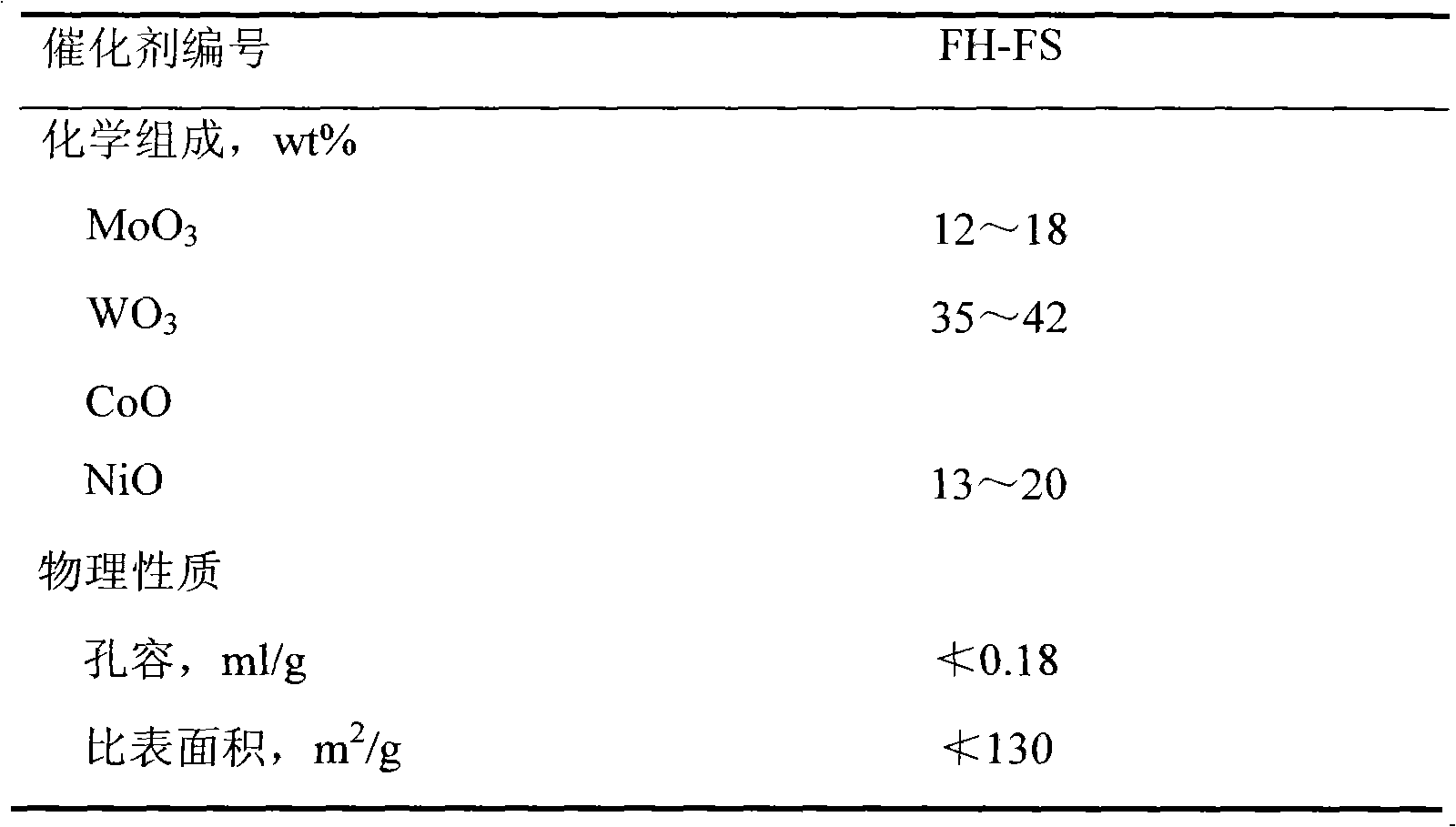

Method used

Image

Examples

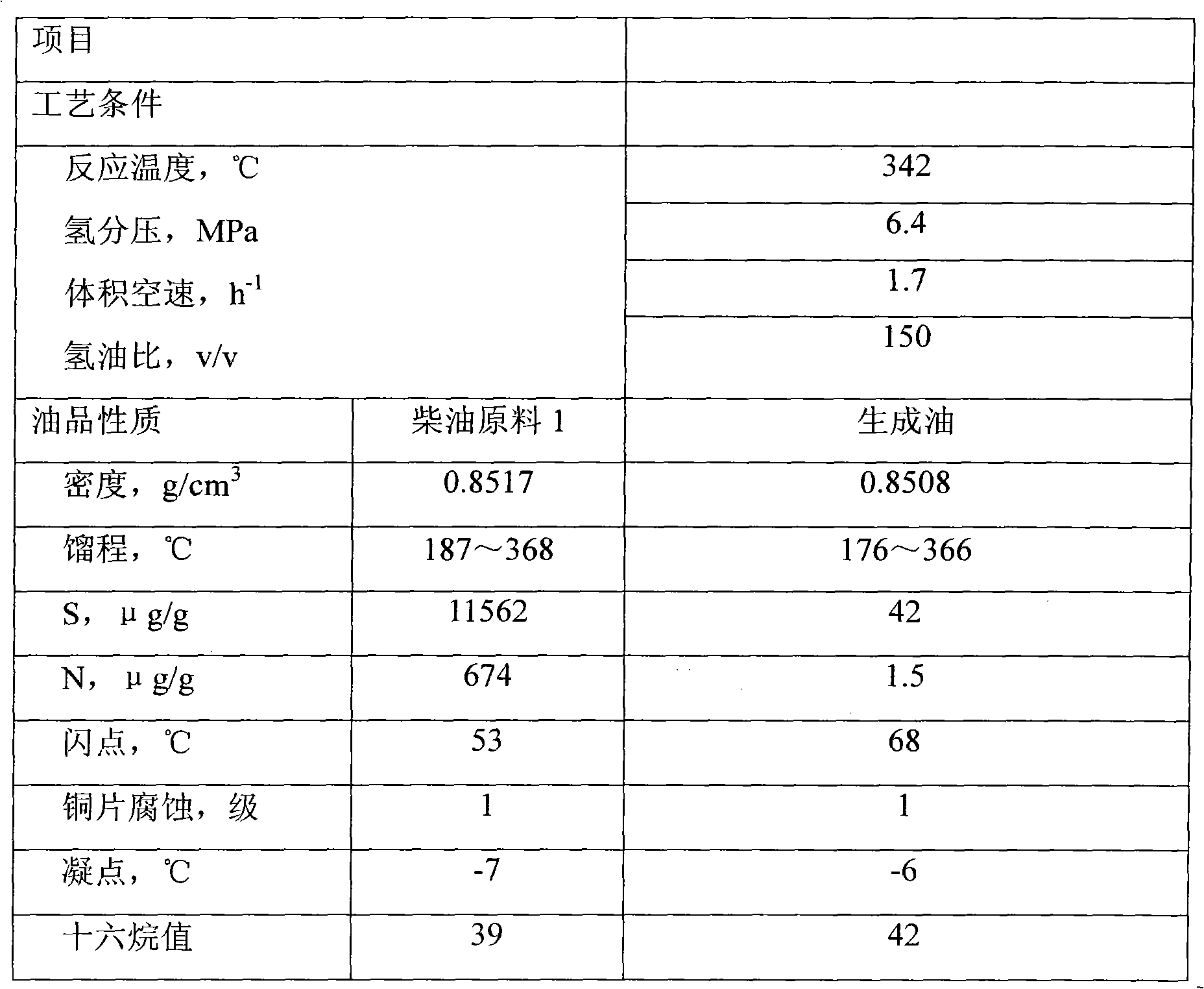

Embodiment 1

[0029] Diesel raw material 1 goes through the heating furnace to reach the required temperature and fully mixes and dissolves hydrogen in the SV static mixer, then enters the hydrogenation reactor. The reaction conditions are: hydrogen partial pressure 6.4MPa, volume space velocity 1.7h -1 , The reaction temperature is 342°C, and the volume ratio of hydrogen to oil is 150:1. The raw material oil properties and product properties are listed in Table 2.

[0030] It can be seen from Table 2 that the sulfur content of diesel products can be reduced to below 50 μg / g by using this technology.

Embodiment 2

[0032] Diesel raw material 2 is fully mixed with hydrogen and enters the hydrogenation reactor after passing through the heating furnace. The gas-liquid mixer adopts SK type static mixer. The reaction conditions are: hydrogen pressure 5.8MPa, volume space velocity 1.5h -1 , The reaction temperature is 337°C, and the volume ratio of hydrogen to oil is 136:1. The raw material oil properties and product properties are listed in Table 3.

[0033] It can be seen from Table 3 that the sulfur content of diesel products can be reduced to below 50 μg / g by using this technology.

Embodiment 3

[0035] Diesel raw material 3 is fully mixed with hydrogen and enters the hydrogenation reactor after passing through the heating furnace. The reaction conditions are: hydrogen partial pressure 7.0MPa, volume space velocity 1.4h -1 , The reaction temperature is 346°C, and the volume ratio of hydrogen to oil is 210:1. Half of the hydrogen is mixed with the raw materials through the SV-type gas-liquid mixer, and the other half is directly added to the reactor through the pipeline. The raw material oil properties and product properties are listed in Table 4.

[0036] It can be seen from Table 4 that the sulfur content of diesel products can be reduced to below 50 μg / g by using this technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com