LED lamp for eliminating glare

A technology of LED light tubes and LED modules, applied in the field of LED light tubes, can solve problems such as waste, increased light loss, and difficulty in eliminating glare, and achieve the effects of soft light, low light loss, and increased light extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

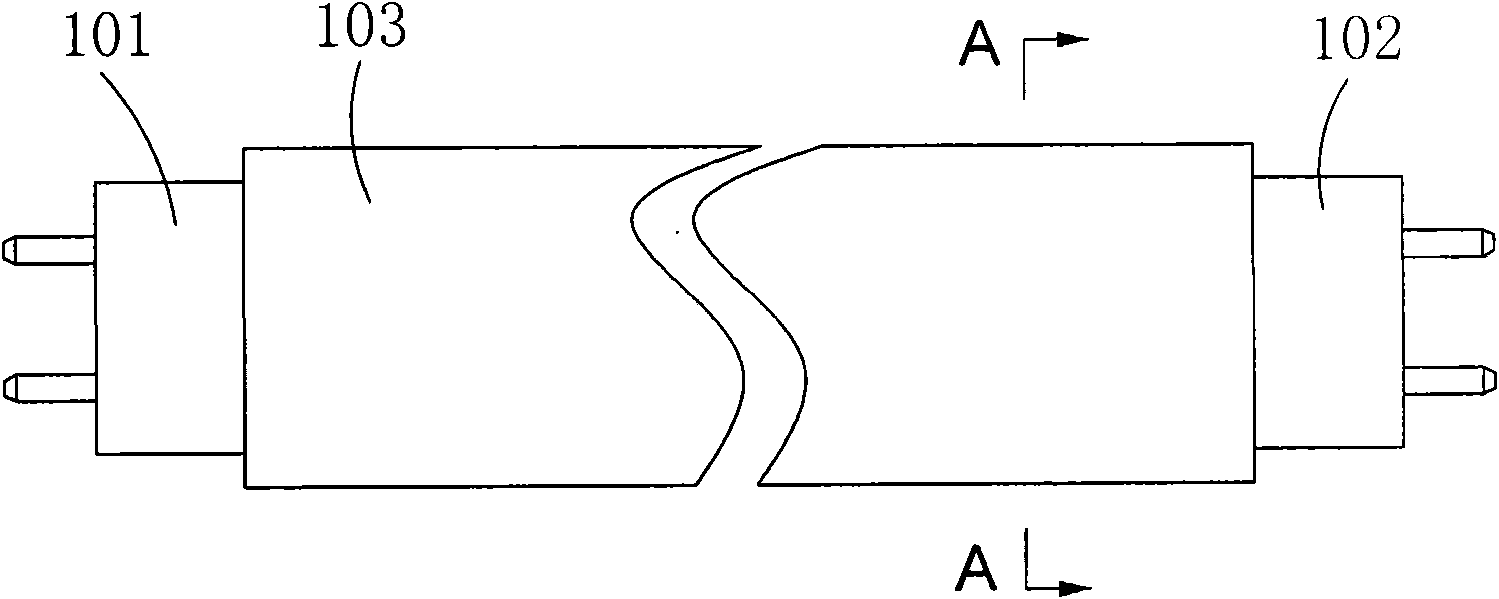

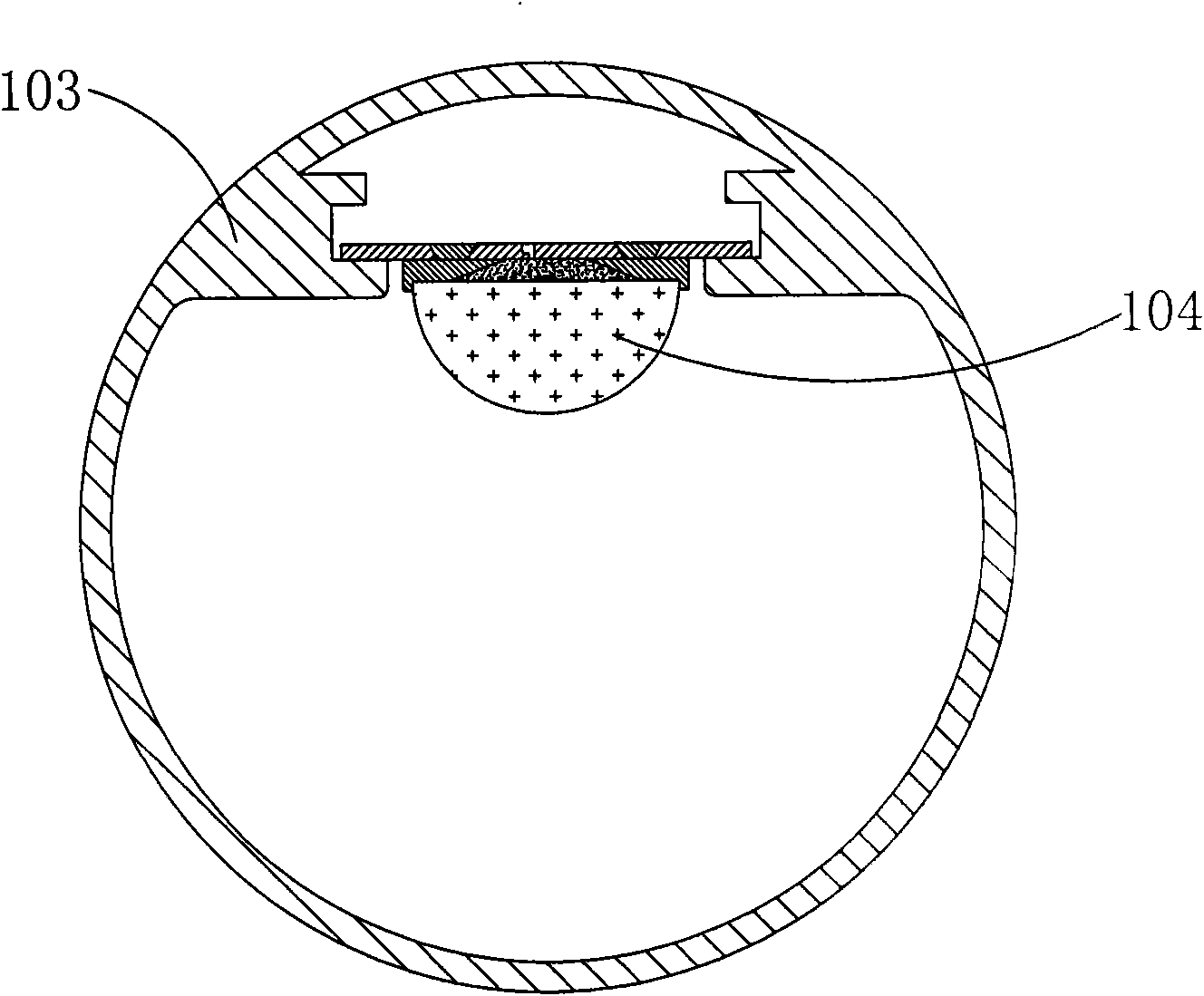

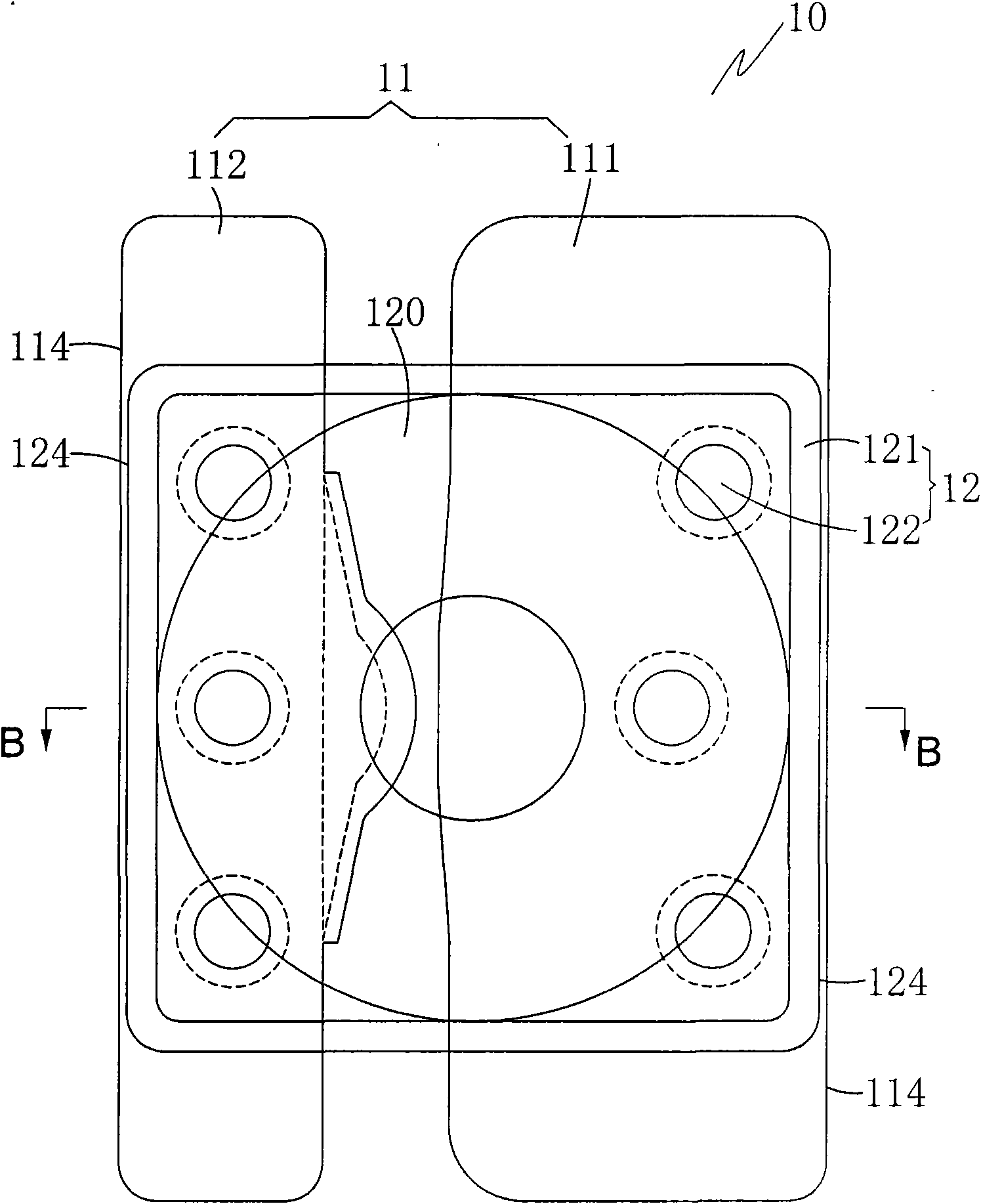

[0027] to combine Figure 1 to Figure 3 As shown, this figure provides a series-connected module 104 structure of the lamp tube 100, the positive plate 111 of the aluminum substrate 11 of any one of the base unit 10 in the base 1 of the lamp tube 100 in this embodiment The negative electrode plate 112 of the aluminum substrate 11 of the adjacent base unit 10 is pressed side by side to form a series connection.

Embodiment 2

[0029] to combine figure 1 , figure 2 and Figure 4 as shown, Figure 4 A series module 104 structure of the lamp tube 100 is also provided, which is an improved structure of the base 1 of the module 104 in the first embodiment, and the positive plate 111 of the aluminum substrate 11 of any one of the base units 10 A series plate 113 is integrally formed with the negative plate 112 which is closely connected side by side with the positive plate 111 , and this series connection is more stable.

Embodiment 3

[0031] to combine figure 1 , figure 2 and Figure 4 as shown, Figure 5 The lamp tube 100 is provided with a parallel module 104 structure, the positive plate 111 of the aluminum substrate 11 of any one of the base monomers 10 in the base 1 of the lamp tube 100 in this embodiment is connected to the adjacent base monomer 1 The positive plates 111 of the aluminum base plate 11 are closely connected side by side. In addition, the negative plate 112 of the aluminum base plate 11 of any base unit 10 is connected side by side with the negative plate 112 of the aluminum base plate 11 of the adjacent base unit 10 to form a parallel connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com