W flame boiler for avoiding clinkering on water-cooled walls of wing walls and sidewalls by four-corner ventilation

An anti-slagging, wing wall technology, applied in the combustion of block fuel and liquid fuel, the combustion of block fuel and gaseous fuel, the combustion of block fuel and powder fuel, etc., can solve the problem of wing wall and The problems of slagging on the side walls can reduce the melting point of ash, have broad prospects for promotion, and have strong jet rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

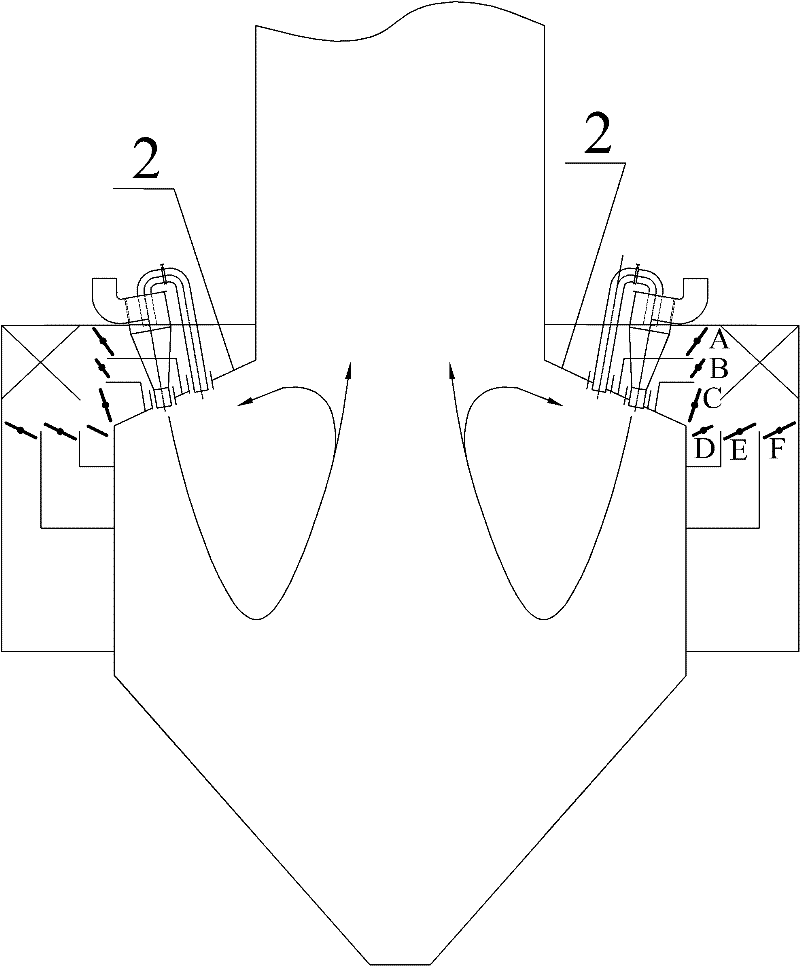

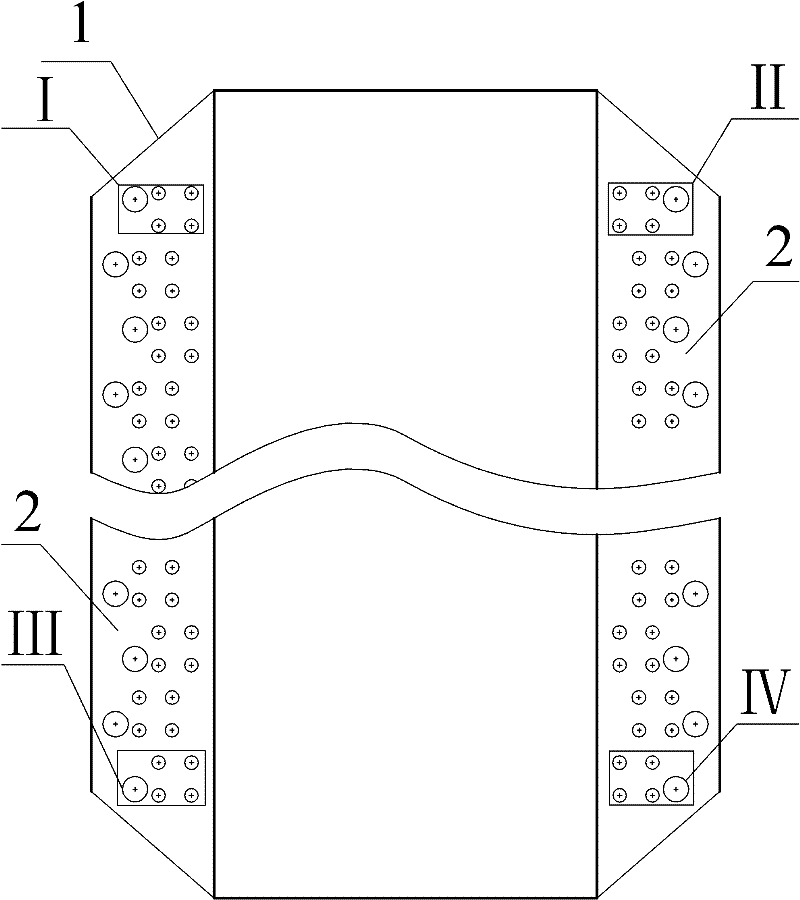

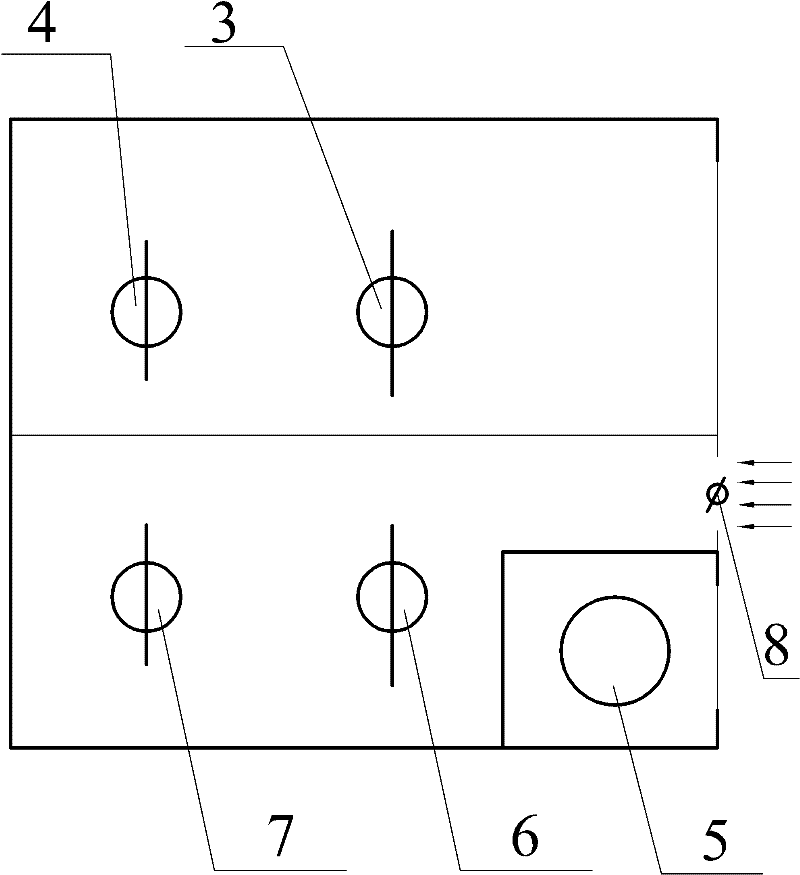

[0010] Specific implementation mode one: as Figure 1~3 As shown, the W-flame boiler with four-corner ventilation to prevent slagging of the wing wall and the side wall water wall in this embodiment includes a wing wall 1 and a furnace arch 2, and the furnace arch 2 near the four-corner wing wall of the W flame boiler is respectively set There are the first group of nozzles I for connecting to the burner, the second group of nozzles II for connecting to the burner, the third group of nozzles III for connecting to the burner and the fourth group of nozzles for connecting to the burner Nozzle IV, the above four groups of nozzles used to connect with the burner are composed of the far wing wall thick coal powder flow nozzle 3, the far wing wall light coal powder flow nozzle 4, the oil secondary air nozzle 5, and the first anti-slagging air nozzle 6 and the second anti-slagging air nozzle 7; from the direction of looking down, the thick coal dust airflow nozzle 3 of the far wing w...

specific Embodiment approach 2

[0012] Specific implementation mode two: as Figure 4 As shown, the cross-sectional area of the thick coal pulverized gas flow nozzle 3 of the far wing wall described in this embodiment is 0.1m 2 , the cross-sectional area of the far wing wall light coal pulverized gas flow nozzle 4 is 0.1m 2 . That is, the thick pulverized coal spout 3 of the far wing wall is double of the thick pulverized coal spout of the original far wing wall, and the area of the light pulverized coal airflow spout 4 of the far wing wall is twice of the light pulverized coal spout of the original far wing wall , and the other orifice areas remain unchanged. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0013] Embodiment 3: The W flame boiler in this embodiment also includes a fan and a wind box, and the fan and the wind box are connected to the first anti-slagging air nozzle 6 and the second anti-slagging air nozzle 7 through the anti-slagging air duct. The anti-slagging air is provided by a separate fan and bellows, and the anti-slagging air duct is connected to the anti-slagging air nozzle, thereby increasing the adjustable range of the anti-slagging air volume and improving combustion efficiency. Other compositions and connections are the same as those in Embodiment 1 or 2.

[0014] Anti-slagging principle: The anti-slagging air is drawn out from the secondary air box or a separate air box, and is directly injected into the lower furnace through the anti-slagging air nozzle. The anti-slagging wind can effectively prevent the slagging of the wing wall and the water-cooled wall of the side wall. Into the lower furnace, increase the distance between the dense pulverized coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com