Control circuit of quick ignition device of gas cooker

A rapid ignition and control circuit technology, applied to heating fuel, household stove/stove, gaseous heating fuel, etc., can solve problems such as safety hazards, gas leakage, and reducing the safety of gas cookers, so as to prevent gas leakage and ensure The effect of gas safety, improving the safety and reliability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

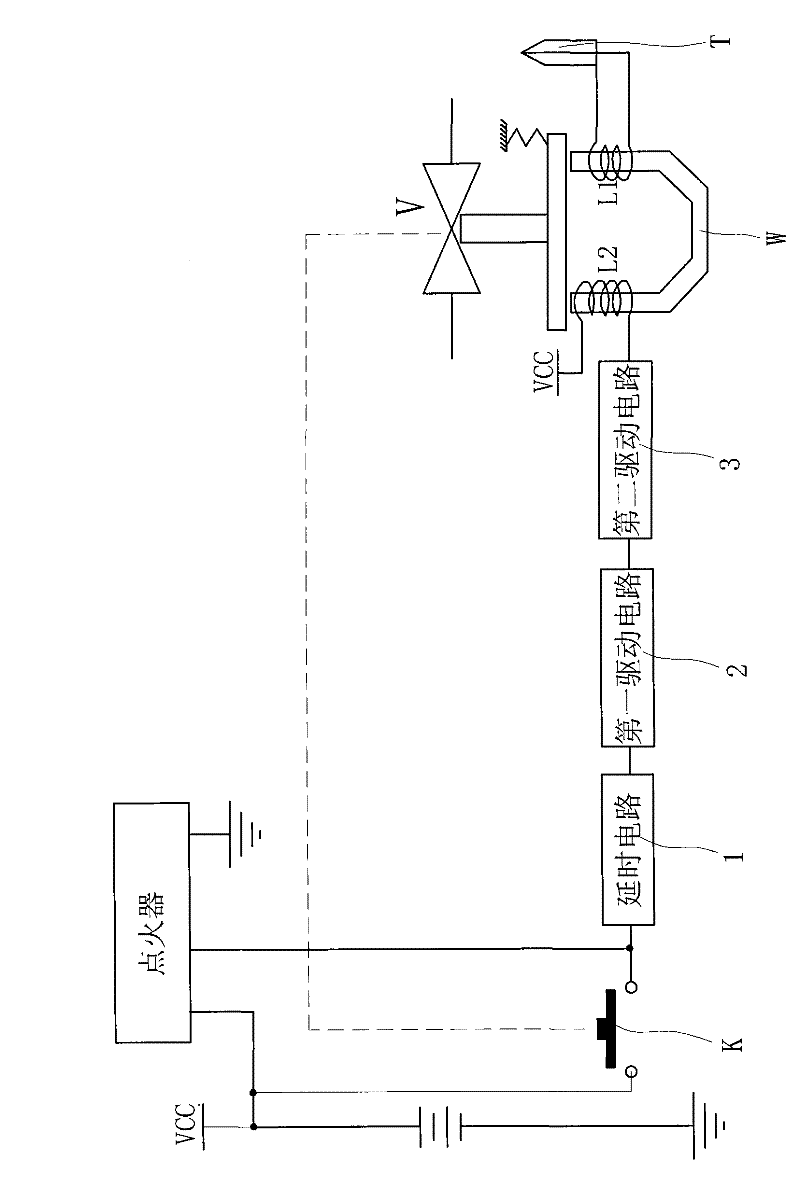

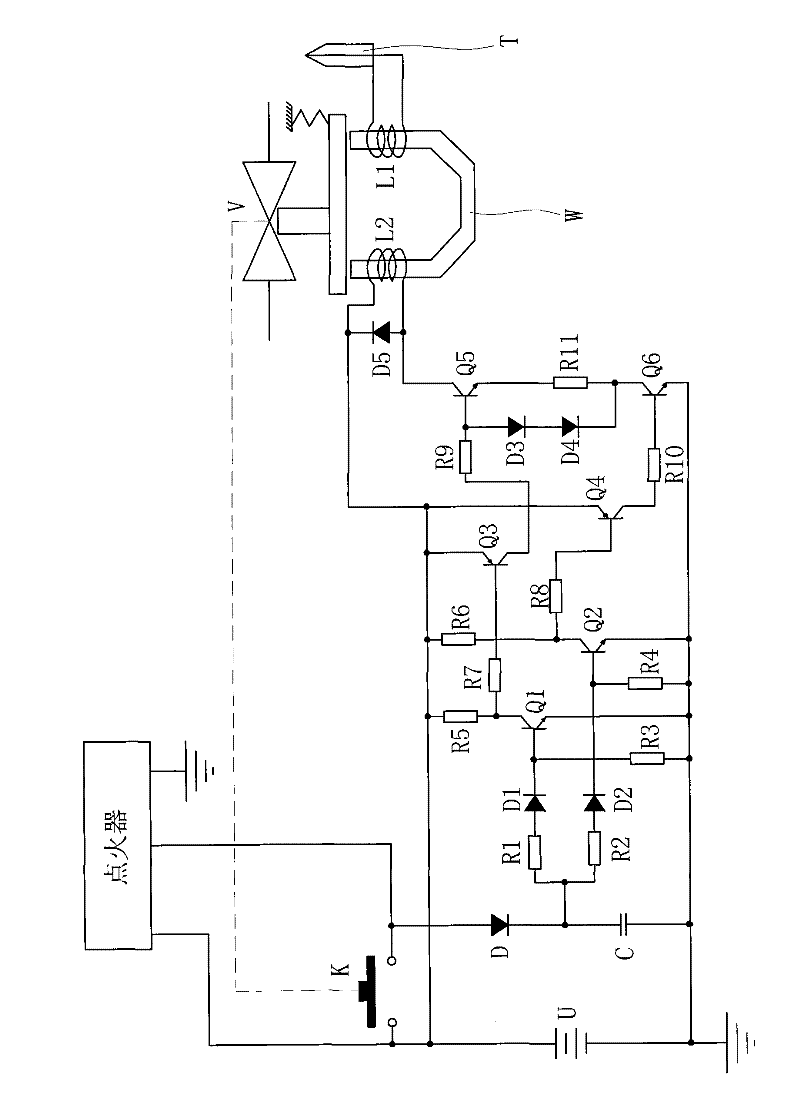

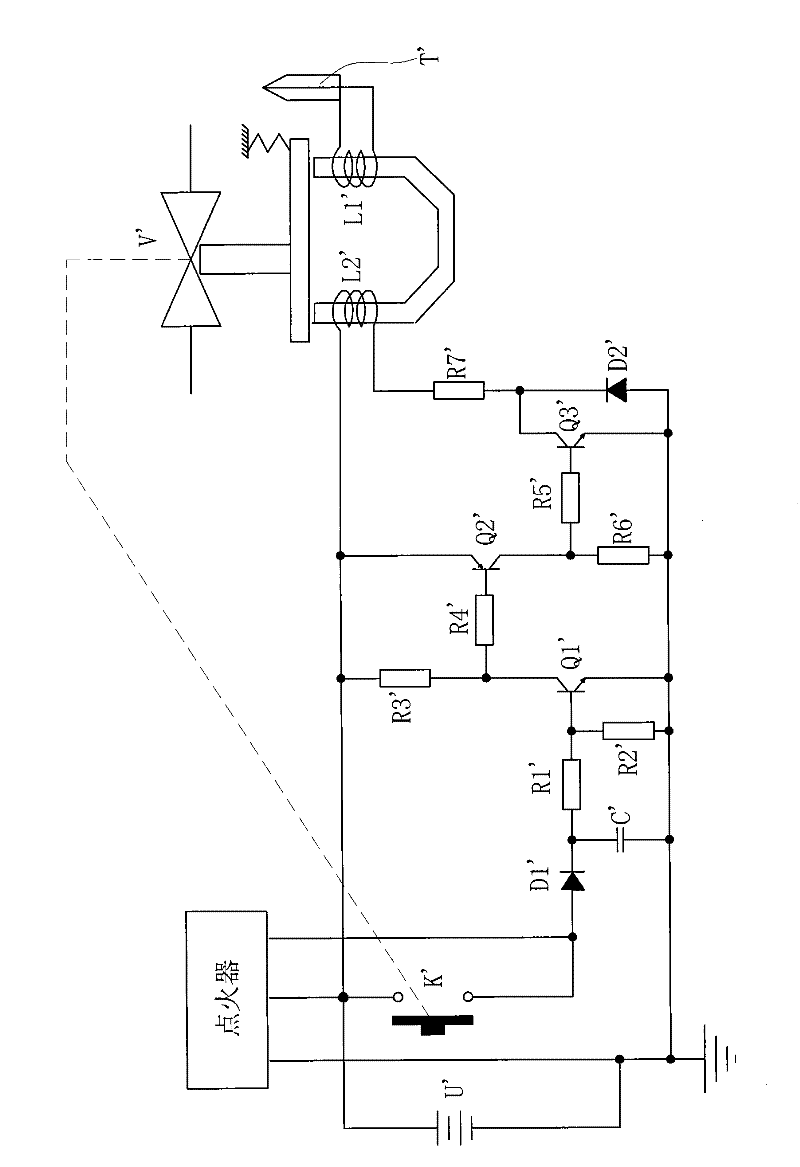

[0025] Such as figure 1Shown is the schematic circuit diagram of the embodiment of the present invention. The ignition device of the gas stove in this embodiment is provided with a delay circuit and a thermocouple, which not only has the function of rapid ignition, but also can effectively prevent accidental flameout after the ignition switch is turned off. Among them, the control circuit of the ignition device includes

[0026] The power supply U of the igniter is taken from the battery on the gas cooker, and the ignition switch K is connected in series to the power circuit of the igniter. After the ignition switch K is closed, the igniter will generate a high-voltage pulse signal to the ignition needle (in the figure not shown);

[0027] Solenoid valve V, which includes a U-shaped electromagnetic core W and a first coil L1 and a second co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com