Air-fuel ratio control system for internal combustion engine

A control device and air-fuel ratio technology, applied in engine control, fuel injection device, fuel injection control, etc., can solve the problem of not being able to obtain the air-fuel ratio control signal SCTL, and achieve the effect of maintaining control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

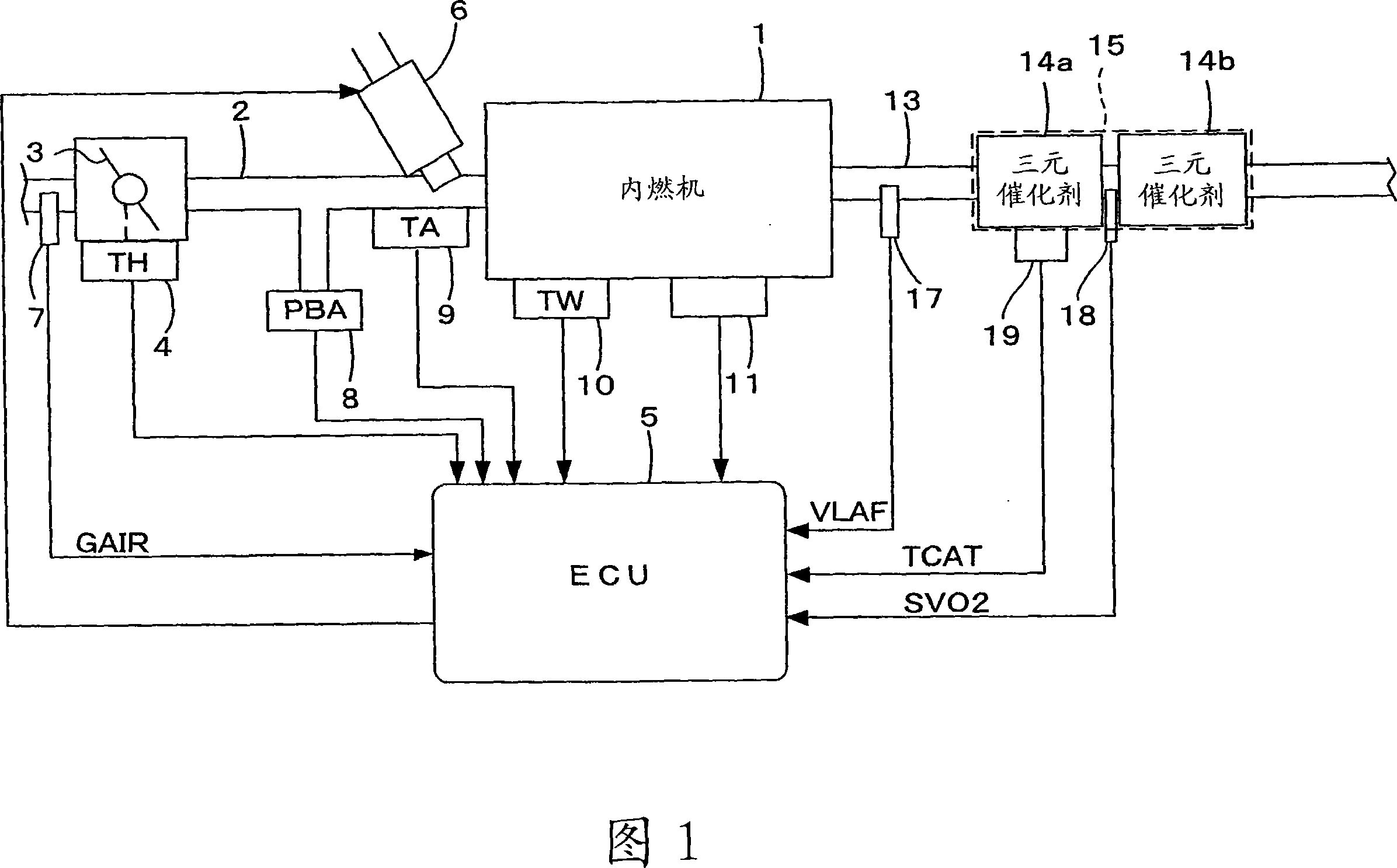

[0035] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0036] 1 is an overall configuration diagram of an internal combustion engine (hereinafter referred to as "engine") and its air-fuel ratio control device according to an embodiment of the present invention. A throttle valve 3 is disposed in the middle of an intake pipe 2 of, for example, a 4-cylinder engine 1 . A throttle opening (TH) sensor 4 is connected to the throttle valve 3 , outputs an electrical signal corresponding to the opening of the throttle valve 3 , and supplies it to an electronic control unit (hereinafter referred to as “ECU”) 5 .

[0037] The fuel injection valve 6 is arranged for each cylinder, and is arranged between the engine 1 and the throttle valve 3 and slightly upstream of the intake valve (not shown) of the intake pipe 2. The pump is connected and electrically connected to the ECU 5 , and the opening timing of the fuel injection valve 6 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com