Continuous rolling production line of single-strand flat metal wire

A metal wire and production line technology, applied in the field of continuous calendering production line, can solve the problems of low production speed, low efficiency, easy rubbing of burrs, etc., and achieve the effects of improving productivity, high two-dimensional precision, and maintaining tension balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific drawings and embodiments.

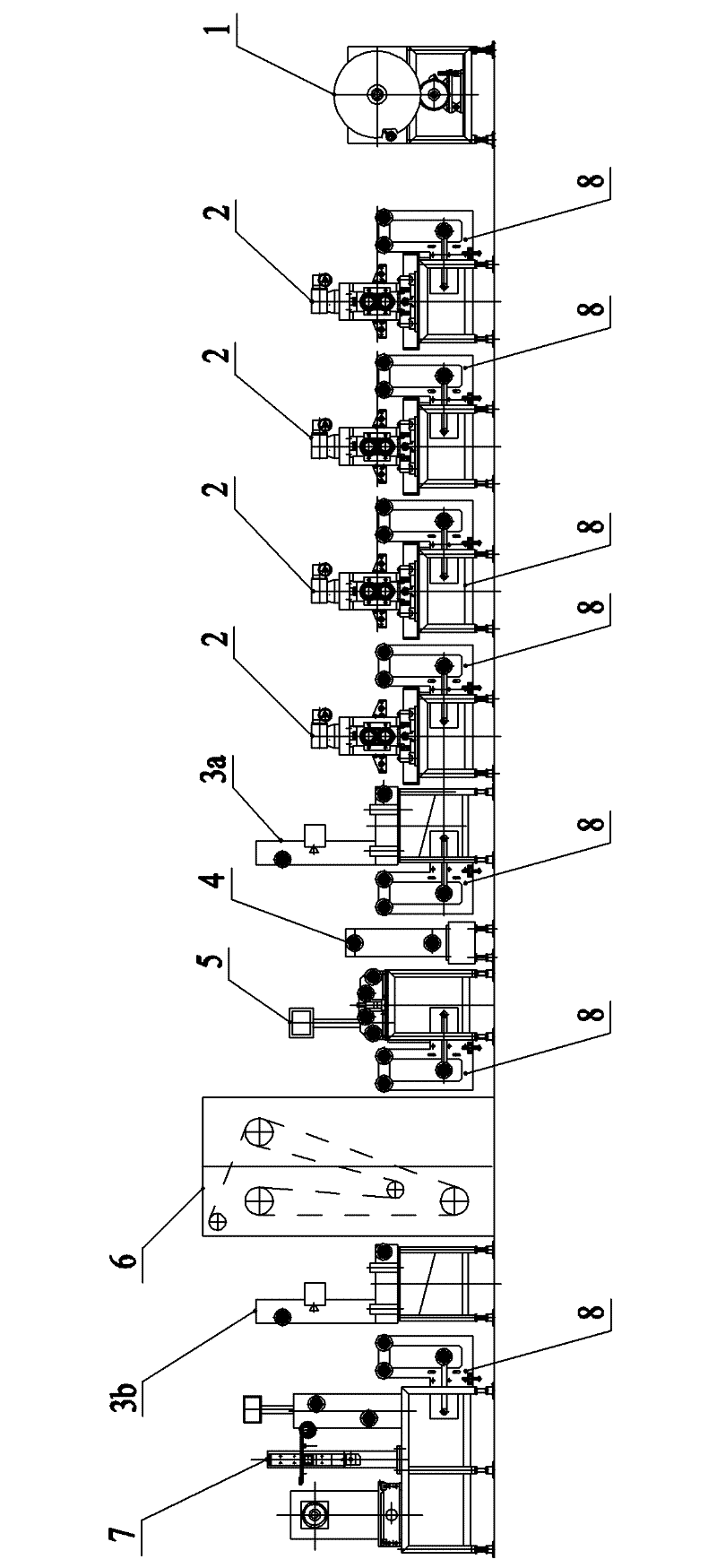

[0030] Such as figure 1 As shown, the single-strand flat metal wire continuous calendering production line in the embodiment is mainly composed of a pay-off machine 1, four calenders 2, a front cleaning and drying machine 3a, a speed pinch-off device 4, an optical thickness measuring device 5, and an on-line An annealing furnace 6, a post-cleaning and drying machine 3b and a metering and take-up device 7 are composed. Such as figure 1 As shown, each calender 2, front washing and drying machine 3a, optical thickness measuring equipment 5 and measuring and taking-up equipment 7 are respectively equipped with a speed distributor 8.

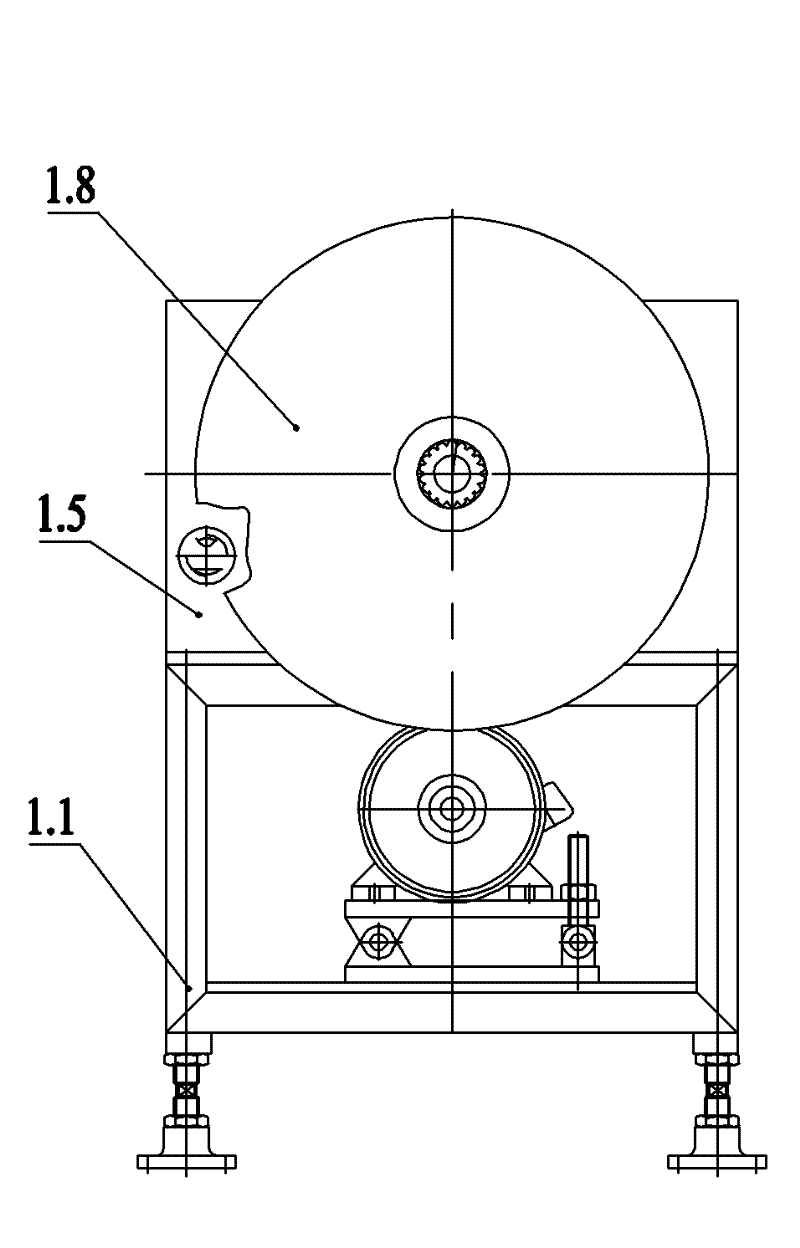

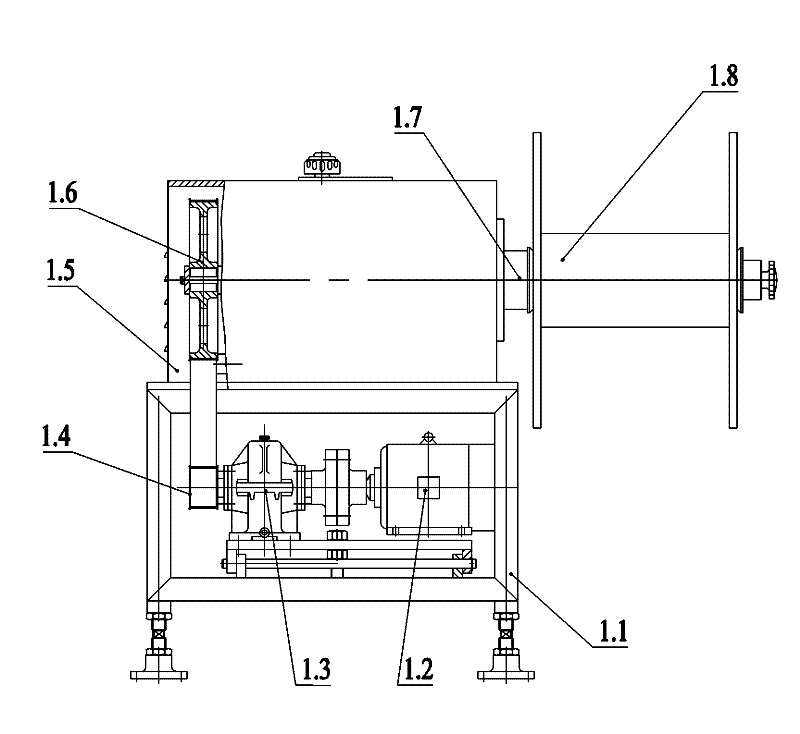

[0031] The structure of the pay-off machine 1 is as Figure 2a , Figure 2bAs shown, it is mainly composed of a pay-off base 1.1, a pay-off motor 1.2, a pay-off reducer 1.3, a pay-off box 1.5, a pay-off shaft 1.7 and a pay-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com