Apparatus and method for completely-mixed fermentation treatment of kitchen/bathroom organic wastes

A technology of complete mixing of organic waste, applied in the direction of organic fertilizers, climate change adaptation, etc., can solve the problems of complex equipment, large power consumption, high management level requirements, etc., to achieve convenient turning operations, keep the ground flat, and improve fermentation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

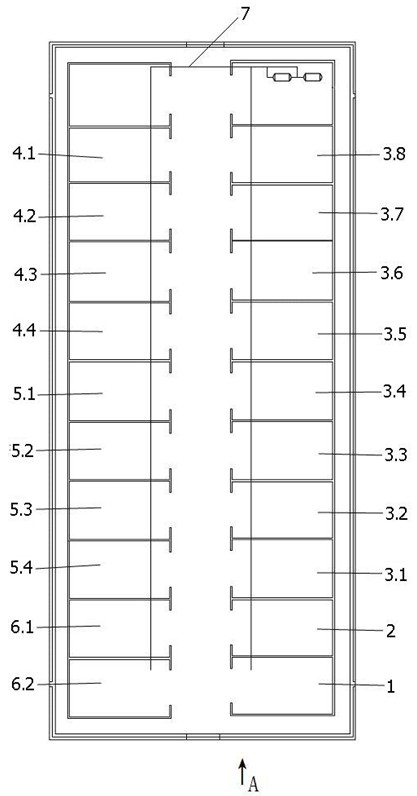

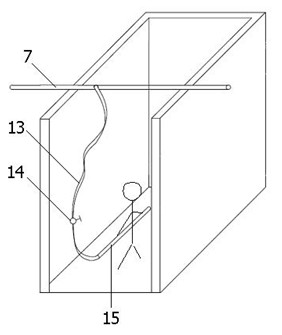

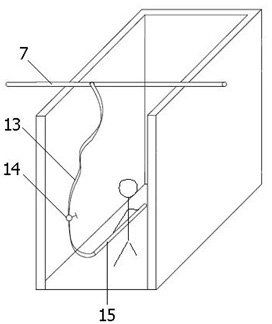

[0028] As shown in Figures 1 and 2, the equipment for completely mixing and fermenting kitchen and bathroom organic waste includes a factory building and a fermentation tank installed in the factory building. It is characterized in that the fermentation tank is divided into a feed pile tank 1 and a mixing tank 2 , a primary fermentation tank 3, a secondary fermentation tank 4, a decomposing tank 5 and a finished product tank 6; a corrugated shielding plate 8 is provided on the top of the workshop; an interval 11 is provided between each of the tank walls and the peripheral walls of the workshop, and the The ground where the interval 11 is located is provided with a water collecting trench 12; the factory building is built with an inflatable oxygen supply pipe 7 connected to an air compressor, and the inflatable oxygen supply pipe 7 communicates with the porous stainless steel pipe 15 placed in each tank.

[0029] The tank walls of the feed stack tank 1, the mixing tank 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com