Production method of grain-fruit mature vinegar

A production method, grain and fruit technology, applied in the production field of grain and fruit mature vinegar, can solve the problems of single flavor of mature vinegar, and achieve the effects of saving equipment, saving food and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

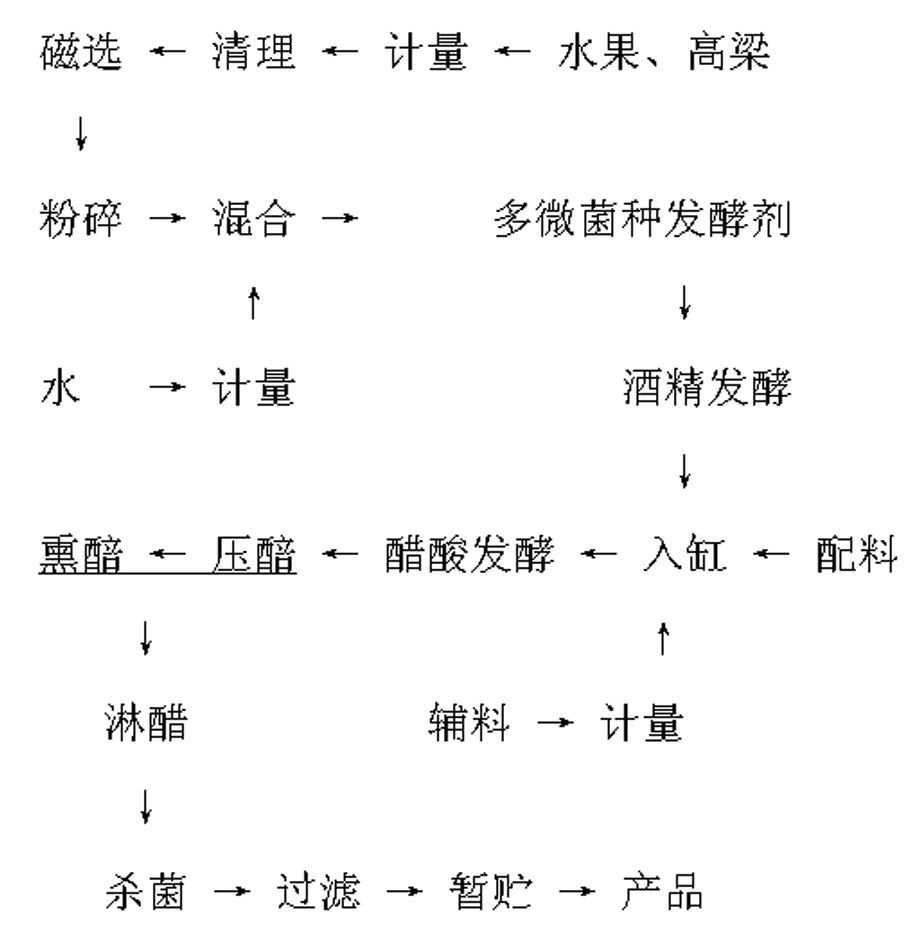

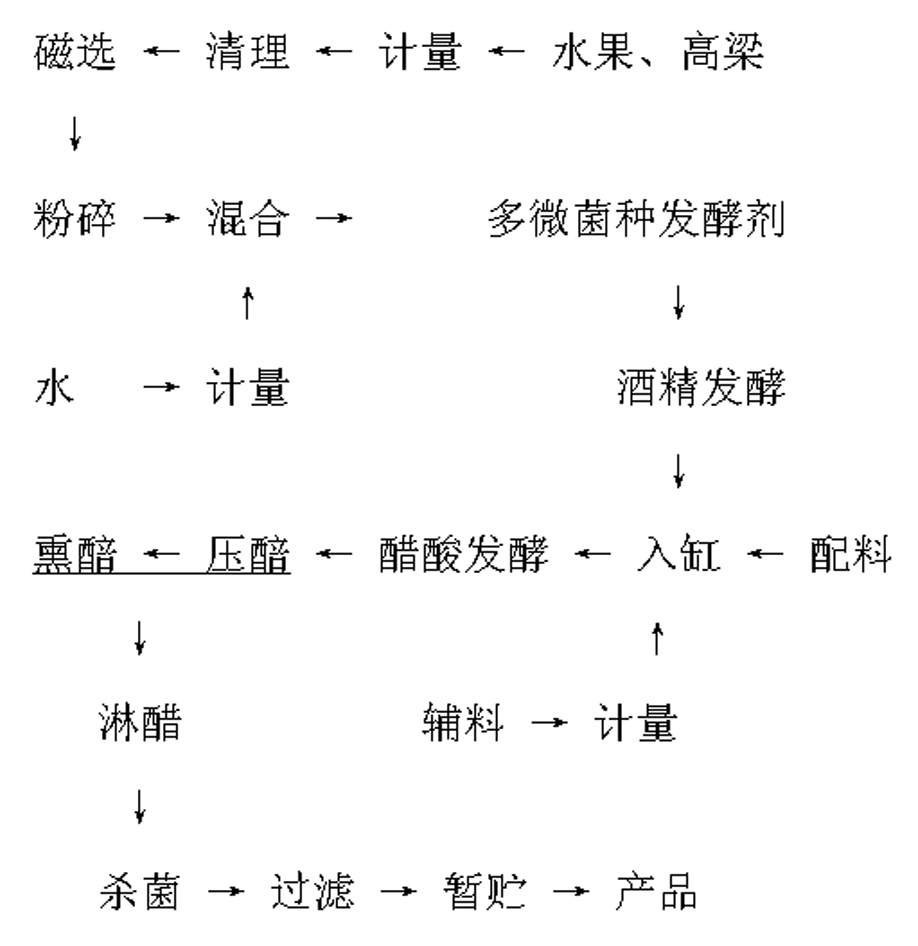

Image

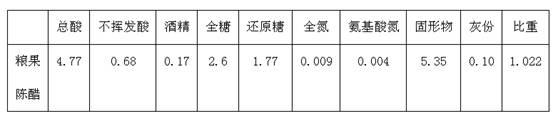

Examples

Embodiment 1

[0012] (1) Materials:

[0013] Grain raw material: sorghum 100kg;

[0014] Fruit raw material: apple 40kg;

[0015] 56kg of multi-microbe strain starter, which is composed of 20% red yeast rice, 20% dakoji, 55% bran yeast and 5% glucoamylase by weight.

[0016] (2) Process steps:

[0017] 1) Crushing of raw materials: After entering the factory, the raw materials need to be crushed through metering, cleaning and magnetic separation.

[0018] 2) Moisturizing and mixing: Add 30-40kg of water to 100kg of raw materials to moisten the crushed raw materials. All raw materials should be moistened evenly with a water content of about 65%.

[0019] 3) Mixing koji: add 40% of the raw material weight polymicrobial starter.

[0020] 4) Alcoholic fermentation: The mixed koji is immediately sent to the alcohol tank in the alcohol fermentation room. The fermentation temperature is controlled at 30-35°C. Rake twice a day for 5 days of static fermentation.

[0021] 5) Acetic acid fermenta...

Embodiment 2

[0028] (1) Materials:

[0029] Grain raw materials: corn 100kg;

[0030] Fruit raw material: apple 60kg;

[0031] 64kg of multi-microbe strain starter, which is composed of 20% red yeast rice, 20% dakoji, 55% bran yeast and 5% glucoamylase by weight.

[0032] (2) The process steps are the same as in Example 1.

Embodiment 3

[0034] (1) Materials:

[0035] Grain raw materials: 60kg corn, 40kg sorghum;

[0036] Fruit raw material: apple 50kg;

[0037] 60kg of multi-microbe strain starter, which is composed of 20% red yeast rice, 20% dakoji, 55% bran yeast and 5% glucoamylase by weight.

[0038] (2) The process steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com