Turbocharger with double ball bearings

A technology of turbocharger and double ball bearings, which is applied in the direction of machines/engines, gas turbine devices, engine components, etc., can solve the problems of slow response to sudden changes in the throttle, high requirements for lubricating oil, and large friction of floating bearings, etc., to achieve start-up Improved responsiveness, less friction, and improved response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

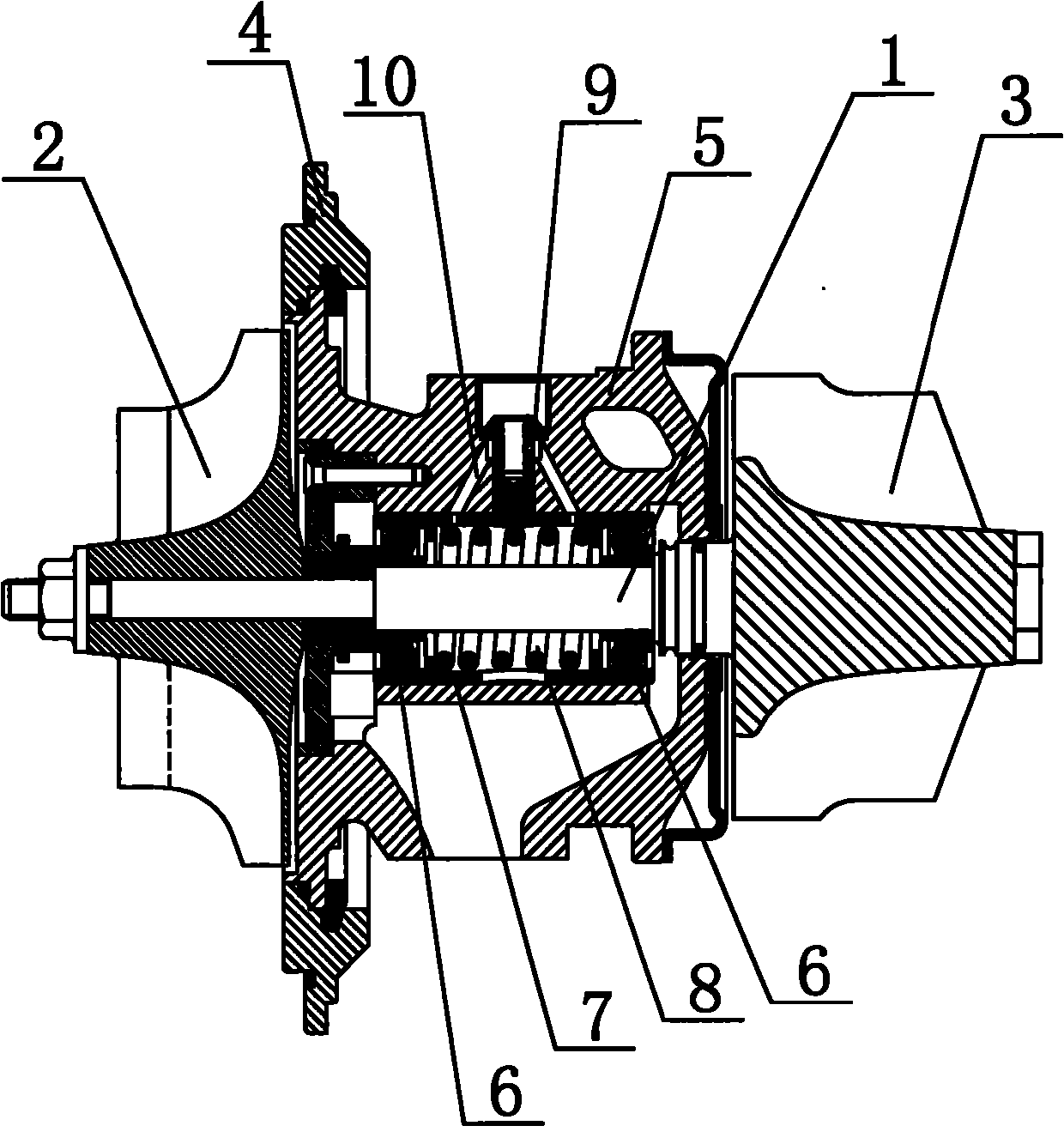

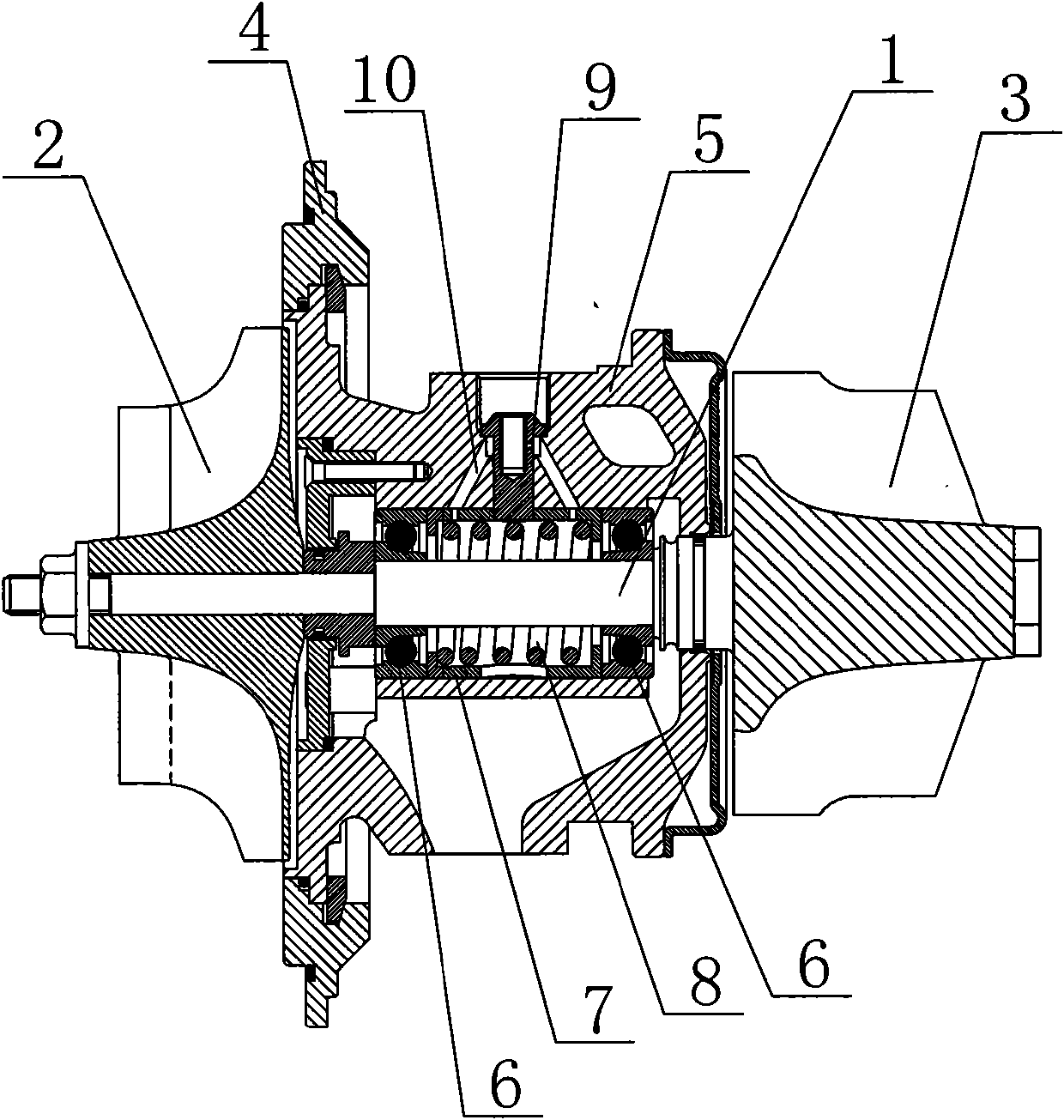

[0013] Please refer to figure 1 as shown, figure 1 It is a structural schematic diagram of the double ball bearing turbocharger of the present invention. In this embodiment, a double ball bearing turbocharger includes a rotor shaft 1 on which a turbine 3 and an impeller 2 are mounted, and the rotor shaft 1 is provided with a supporting An intermediate body 5, on which a diffuser plate 4 is installed, the rotor shaft 1 is supported by two ball bearings 6 located in the intermediate body 5, and bears the axial force generated by the rotor shaft 1, the ball bearings 6 Both are mixed angular contact ceramic ball bearings, and a fixed distance spring sleeve 7 is arranged between the two ball bearings 6, and the fixed distance spring sleeve 7 plays the role of fixing the outer ring of the ball bearing 6, and the fixed distance The spring sleeve 7 is provided with a spring 8, which can prevent the axial impact and vibration of the ball bearing 6 and greatly prolong the service life...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com