Method for checking the state of a pipette, pipetting method, pipetting device, and suction tube for a pipetting device

A technology for pipettes and suction tubes, which is applied in mechanical equipment, measuring tubes/pipettes, chemical instruments and methods, etc., can solve problems such as high cost and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

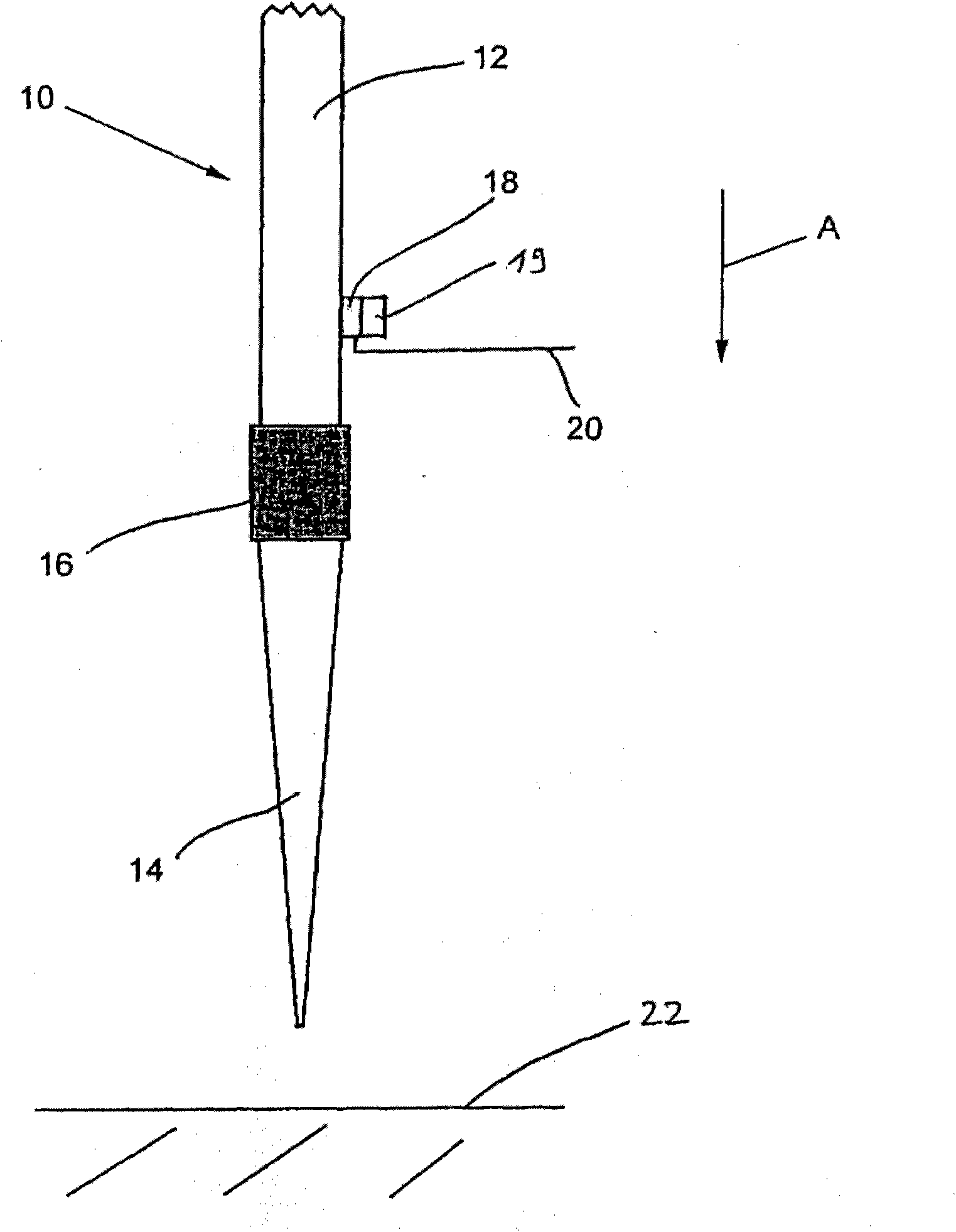

[0053] figure 1 The lower end of the pipette 10 with the pipette tip 14 is shown. The pipette tip has a collar 16 via which the pipette tip 14 is mounted on the aspiration tube 12 . The pipette tip 14 is made, for example, of polypropylene.

[0054] The suction tube 12, only partially depicted, can be used in a fully automated robotic system for pipetting. A suction piston is located in the suction tube 12 in a known manner, which can be driven by a motor shaft to draw liquid into or out of the pipette.

[0055] In other embodiments, the piston is located in an external device that is connected to the suction tube by a hose. Optionally, a suction device, such as a corresponding pump, can also be connected to the suction line.

[0056] Reference numeral 18 denotes a piezoelectric actuator serving as an ultrasonic generator and an ultrasonic receiver. It is advantageous to use elements made of piezoelectric materials, such as lead zirconate titanate ceramics. The piezoelec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com