Intelligent large-scale constant-temperate fermentation room for curdled yoghurt

A technology of coagulated yogurt and constant temperature fermentation, applied in applications, milk preparations, dairy products, etc., can solve the problems of low batch yield and unstable product quality, and achieve high accuracy, small temperature difference and uniform temperature distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

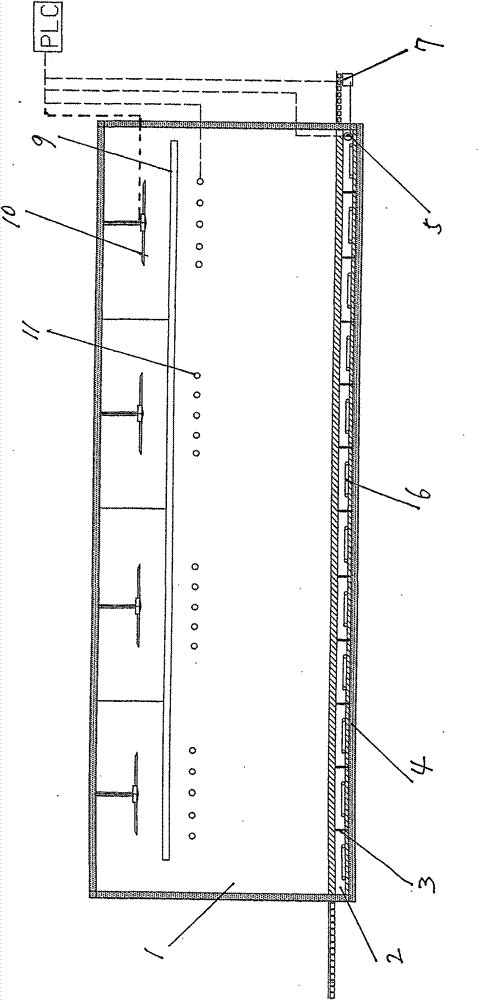

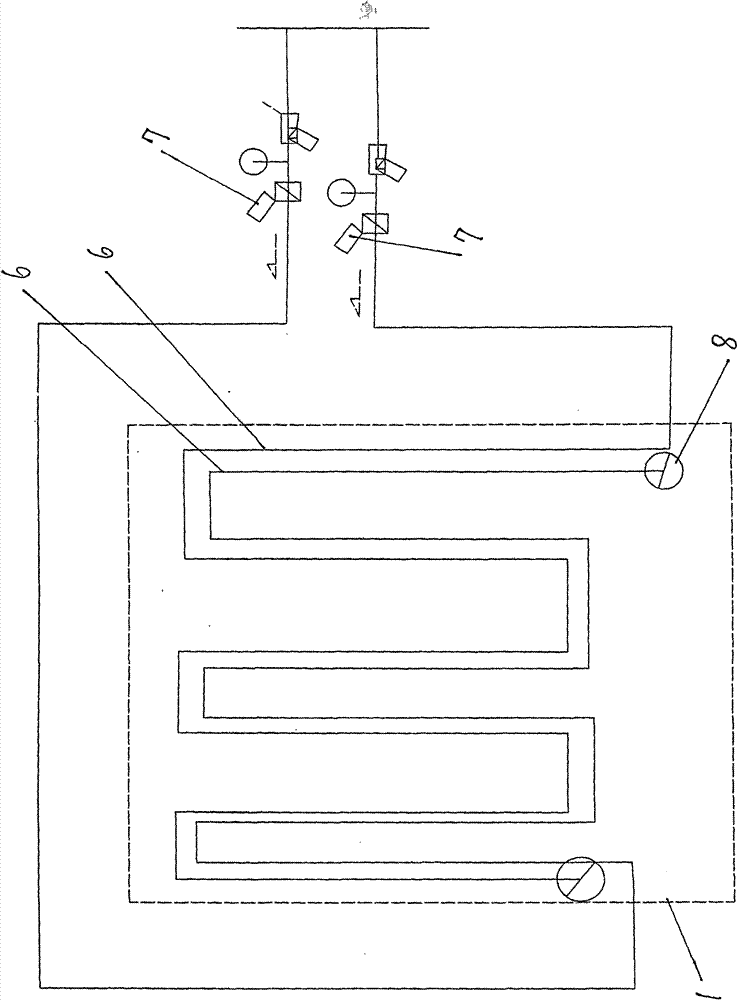

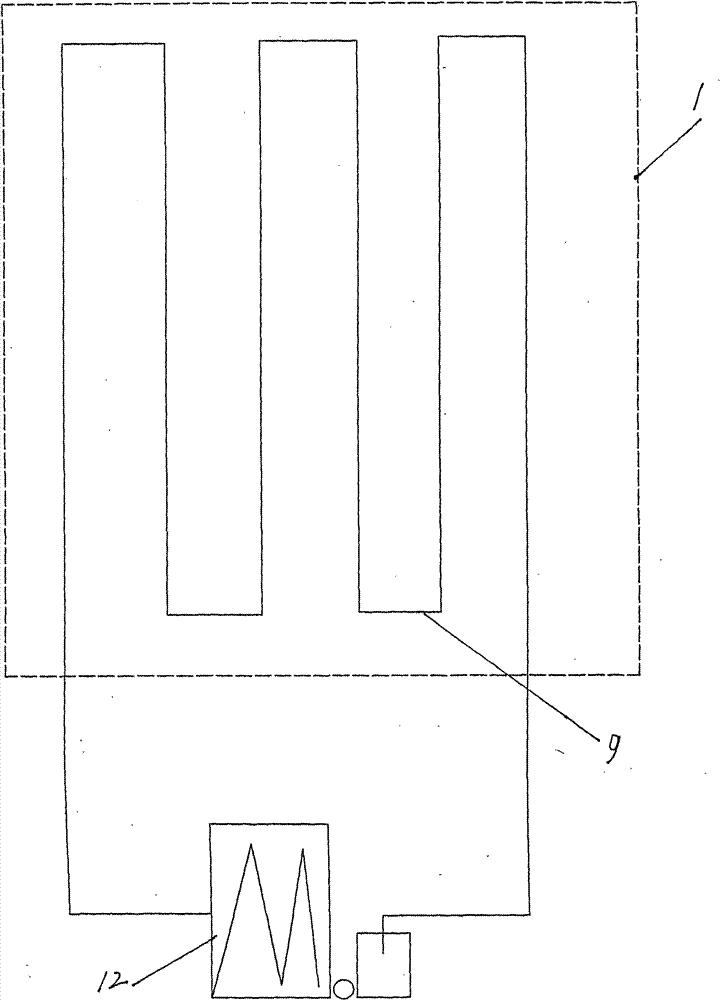

[0021] refer to figure 1 The fermentation room 1 with an area of 100 square meters and a height of 3.5 meters is constructed by using 10 cm thick polyurethane insulation board as the wall and ceiling materials. A 20-centimeter-high interlayer 2 is set downward on the ground of the fermentation room, and a supporting and uniform temperature partition 3 is arranged in the interlayer, so that the interlayer becomes an interconnected uniform greenhouse. A 10-centimeter-thick insulation material layer 4 is laid under the interlayer. The interlayer temperature sensors 5 are placed in the four corners of the interlayer. refer to figure 1 , figure 2 , two parallel steam pipes 6 are installed in the interlayer, and the ends on the same side of the two steam pipes are respectively connected to the air intake solenoid valve 7 and the steam trap 8. refer to figure 1 , image 3 , hot water pipe 9 is installed in the upper part of the fermentation room. Ceiling fan 10 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com