Induction heating system for demolding food products

An induction heating and product technology, applied in induction heating, food science, electric/magnetic/electromagnetic heating, etc., can solve the problems of limited production, loss of product quality, increased downtime, etc., to prevent the formation of water droplets and bacteria risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

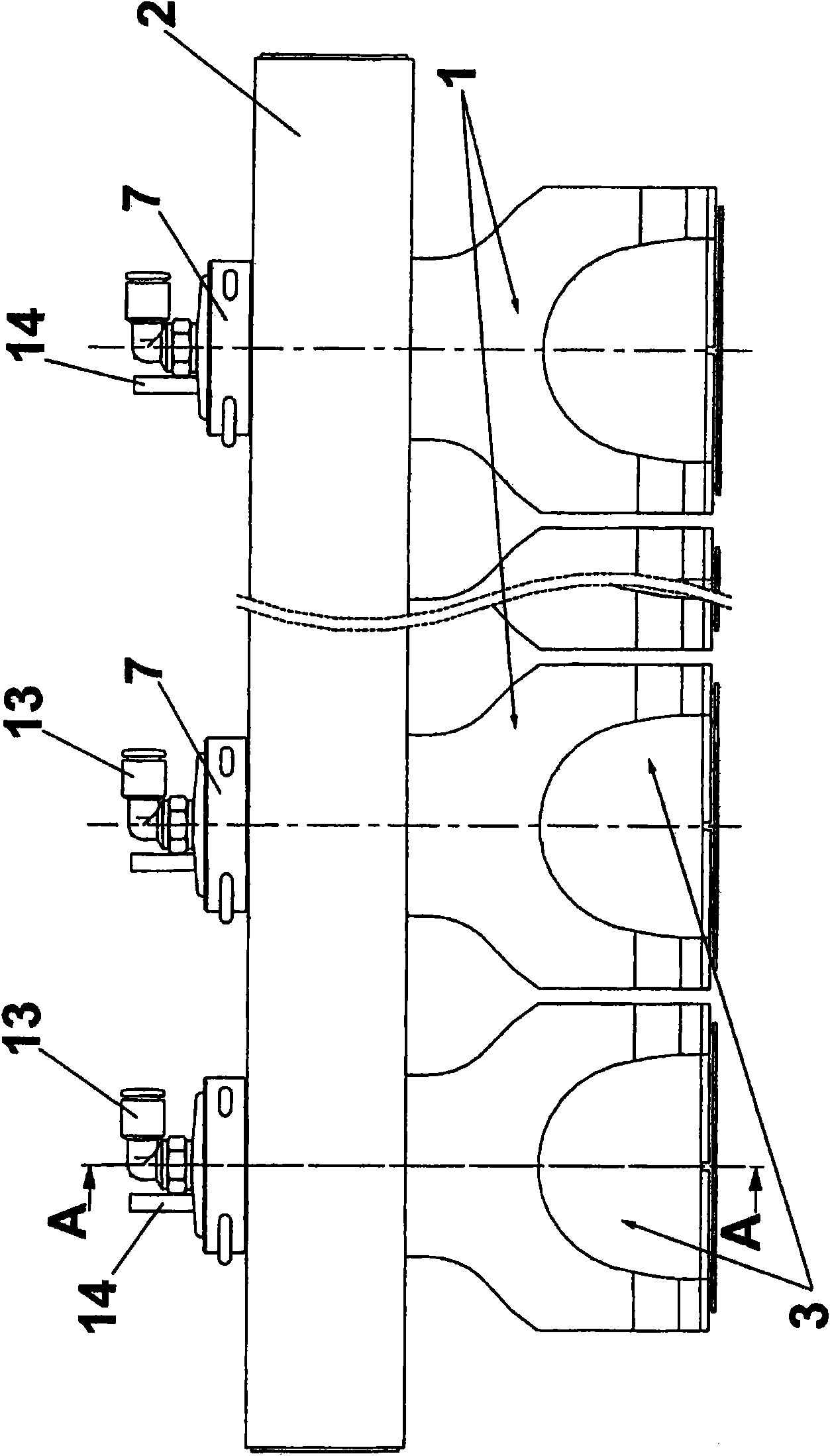

[0025] As can be seen in the figures shown, the heating system (object of the invention) consists of a number of modules 1 mounted on a common support 2 capable of moving down / up to be coupled to a system containing the product intended to be demolded. Multiple other molds3.

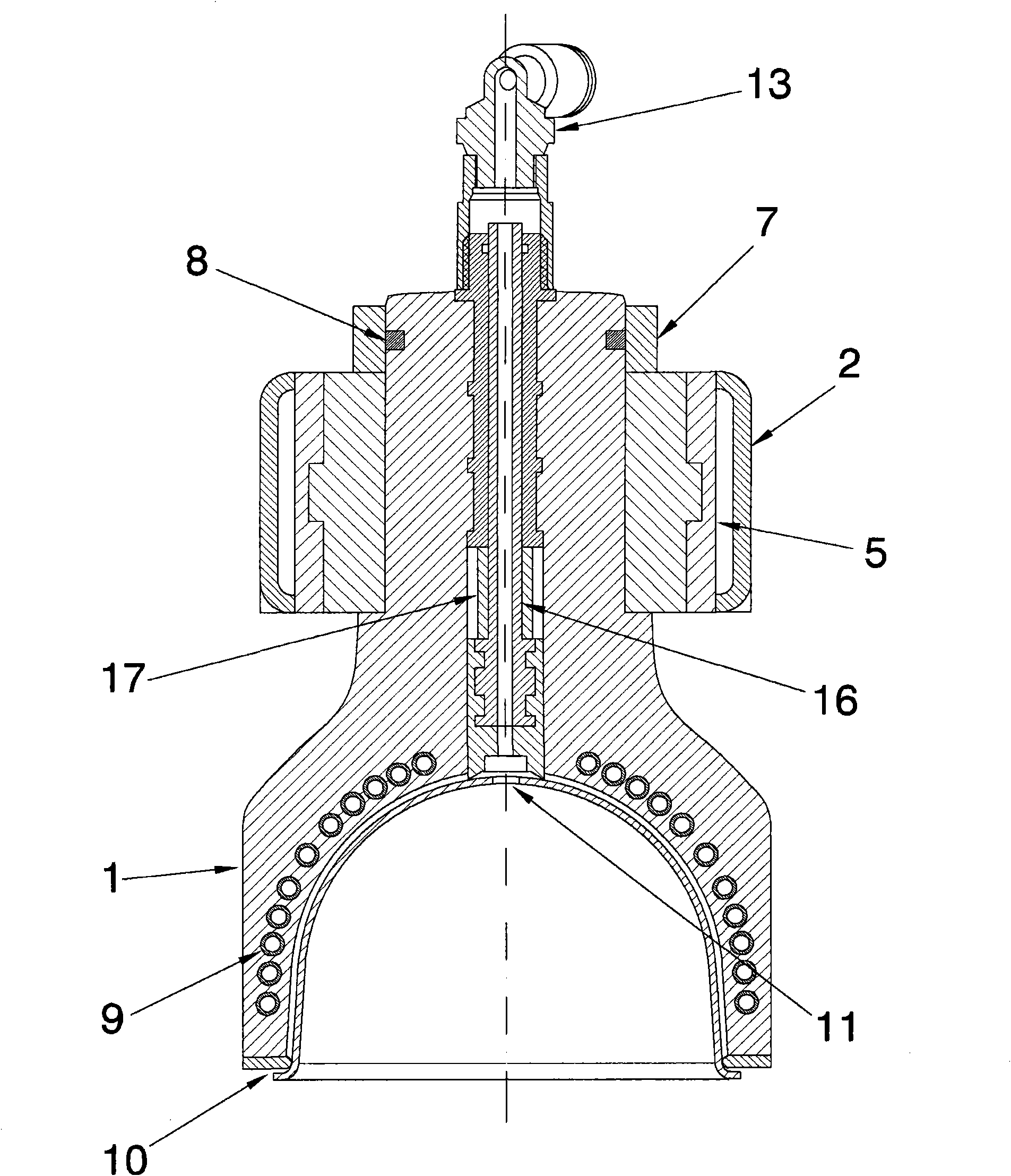

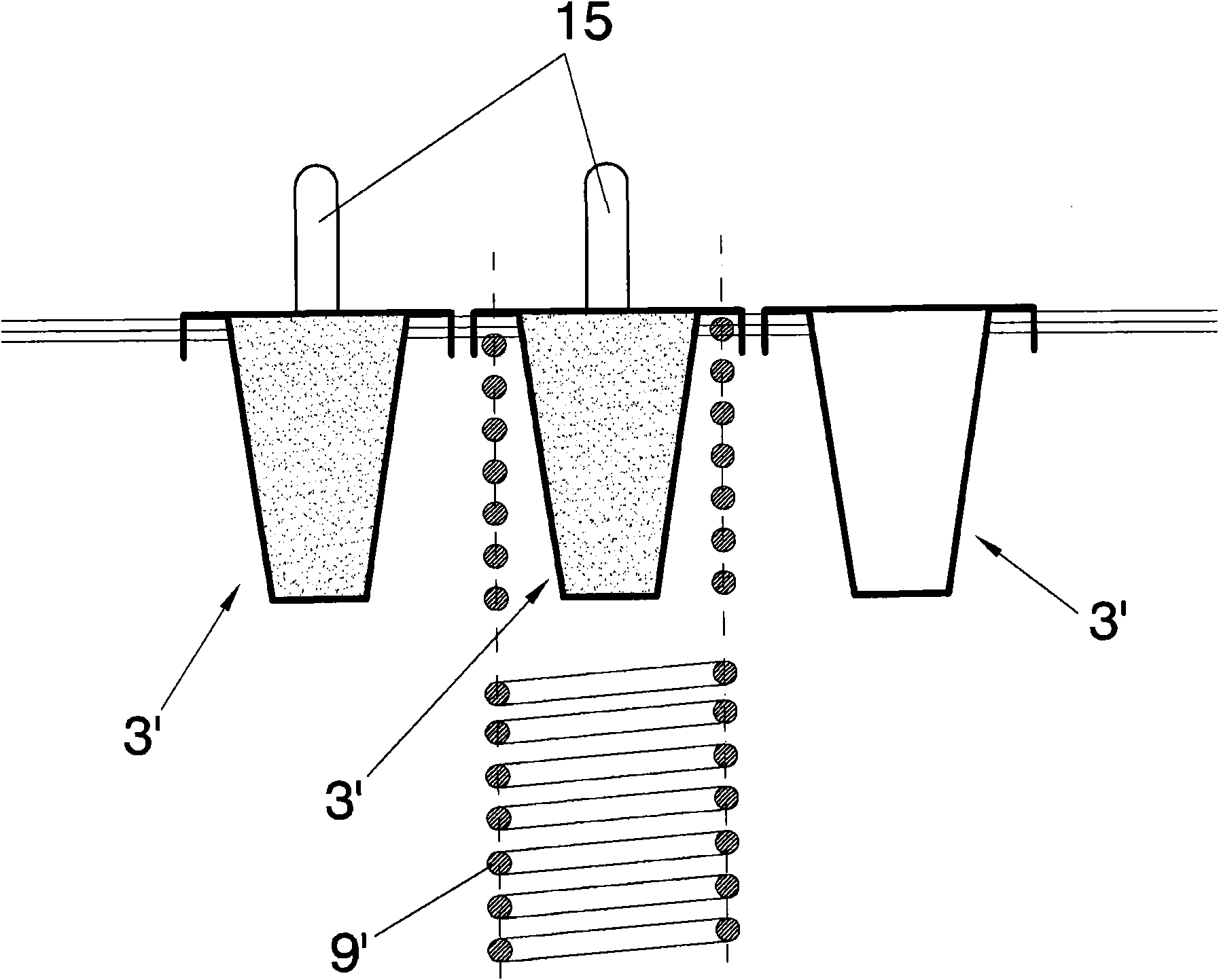

[0026] Each module 1 consists of an injected rigid body 4, such as figure 2 As can be seen in , its lower part forms a cavity around the lower part of the mold 3, wherein the mentioned mold 3 is metallic and hemispherical in shape, but said shape may be any other shape.

[0027] The common support 2 is a rectangular tube in which are located some metal bushings 5 which constitute the housing of a polymer joint 6 which allows coupling to the cylindrical part of the module 1 . Fixing of the components of the system is achieved using the upper ring 7 while inserting the retaining forks 8 .

[0028] Induction coils 9 are mounted around the cavity of the rigid body 4 of each mold 1 so that the resulting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com