Longitudinal beam-free suspension frame with traction mechanisms on transverse beams

The technology of a traction mechanism and a suspension frame is applied in the field of suspension frames, which can solve the problems that the installation of maglev vehicles cannot be fully and effectively used, the cost of maintenance and repair is increased, the structure of the maglev vehicles is not compact enough, and the like. The effect of improving reliability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

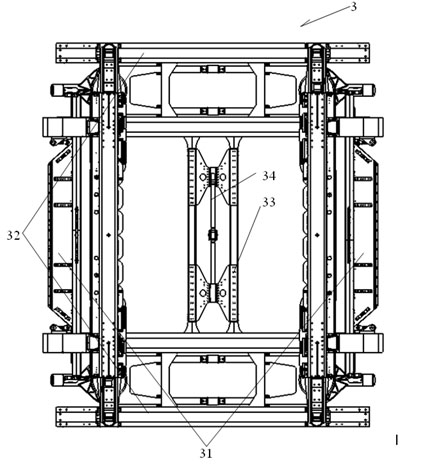

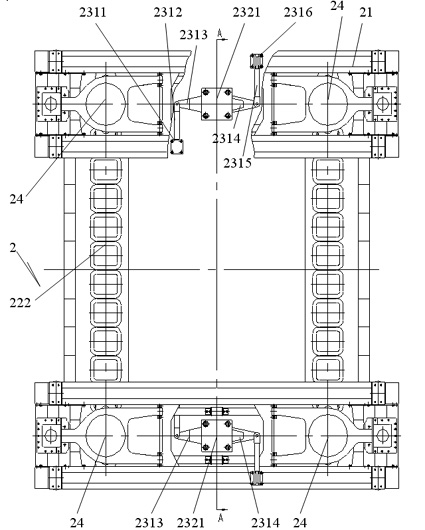

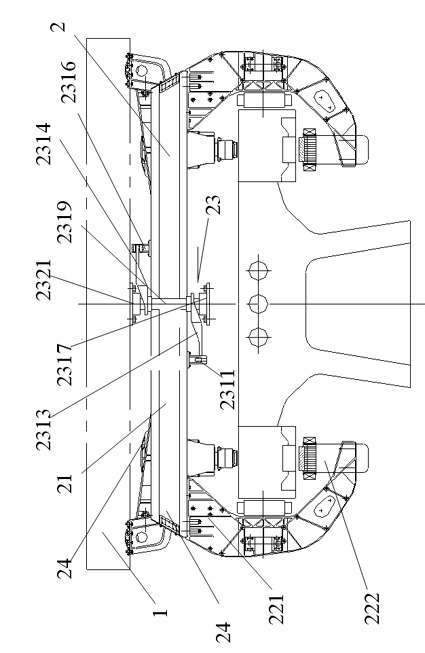

[0036] based on the following Figure 2 ~ Figure 4 , to describe preferred embodiments of the present invention in detail.

[0037] Such as Figure 2 ~ Figure 4 Shown is a front view, a top view, and a cross-sectional view of the front view along the A-A direction of a suspension frame provided by the present invention that has no longitudinal beam and is provided with a traction mechanism on the cross beam.

[0038] Such as figure 2 As shown, a suspension frame without a longitudinal beam and a traction mechanism on the cross beam described in this embodiment is arranged at the bottom of the vehicle body 1 (see image 3 ), including two sets of beams 21 , magnet modules 22 , traction mechanisms and bolsters 24 . Two groups of crossbeams 21 are arranged symmetrically, which are respectively connected with the vehicle body 1. The magnet modules 22 are arranged symmetrically at both ends of each group of crossbeams 21. A traction mechanism is arranged between each group of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com