Environmental-friendly combined conveyor of slag treatment system

A water treatment system and conveyor technology, applied in conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of affecting the slag treatment site environment, unable to remove in time, slag leakage, etc., and achieve simple structure and low cost. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] [specific implementation method]

[0013] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

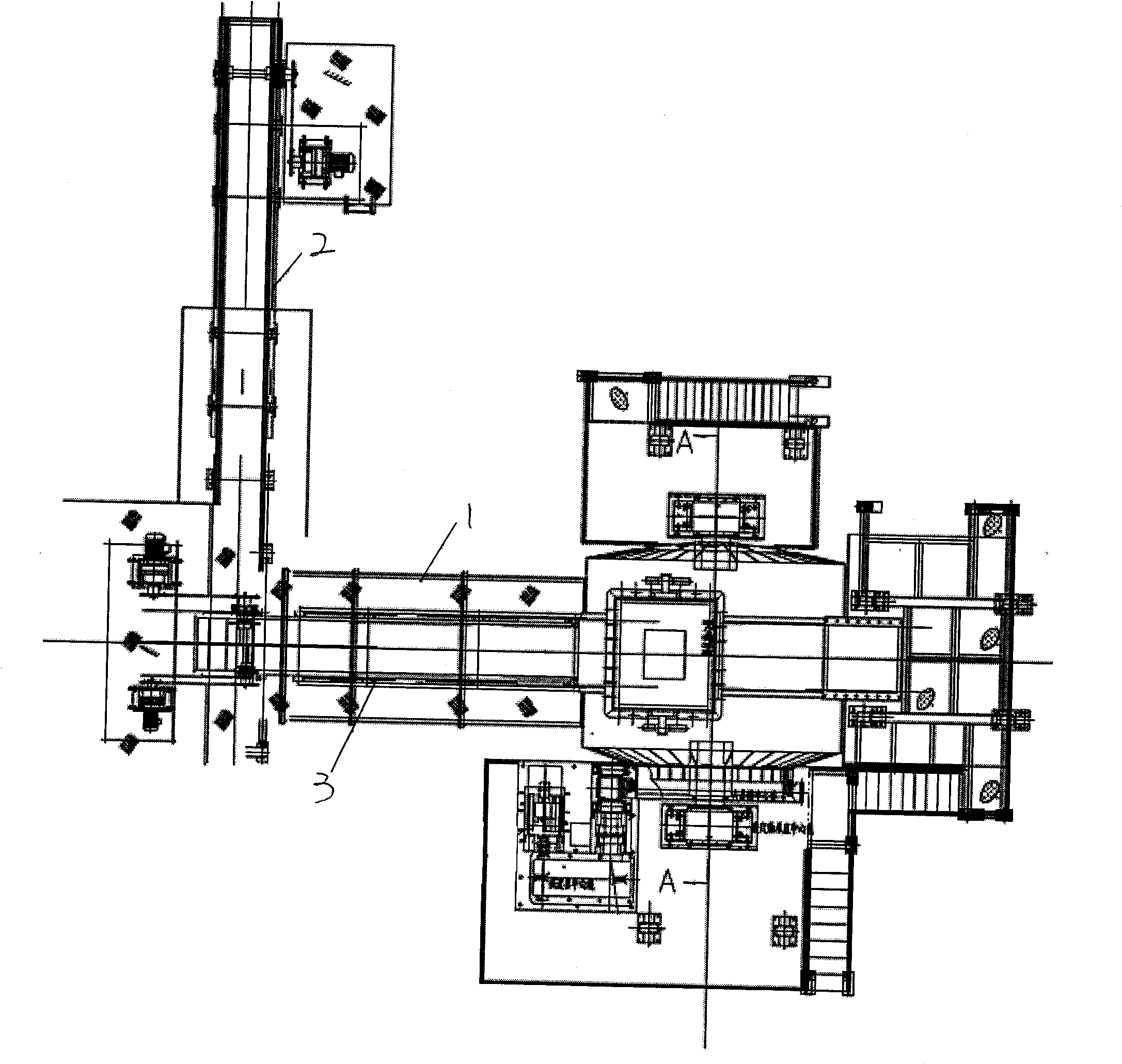

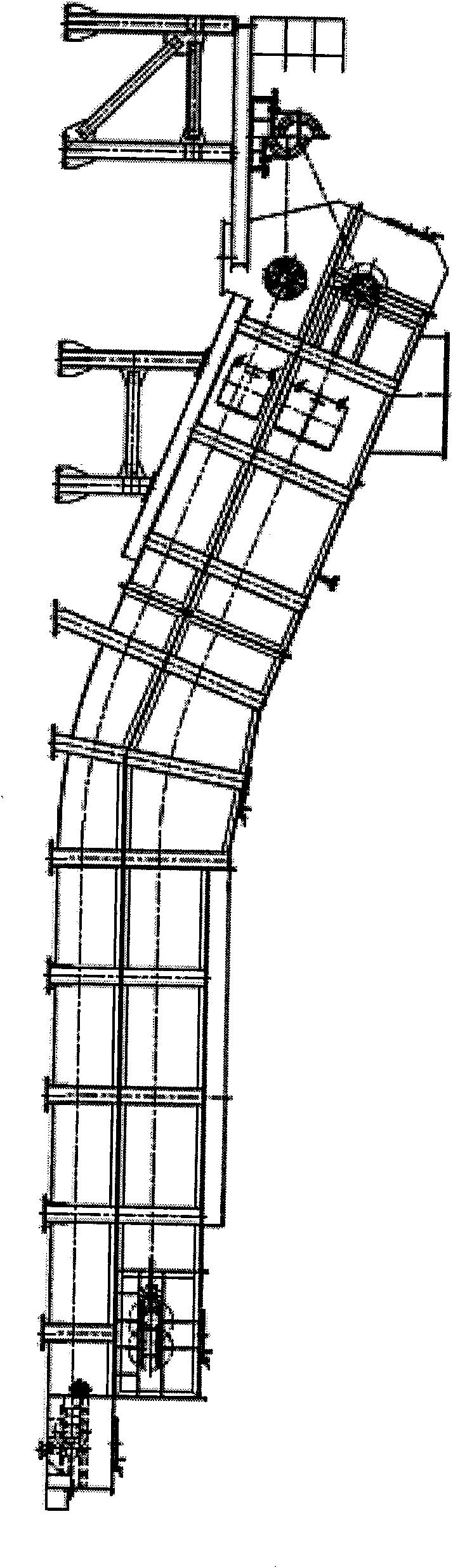

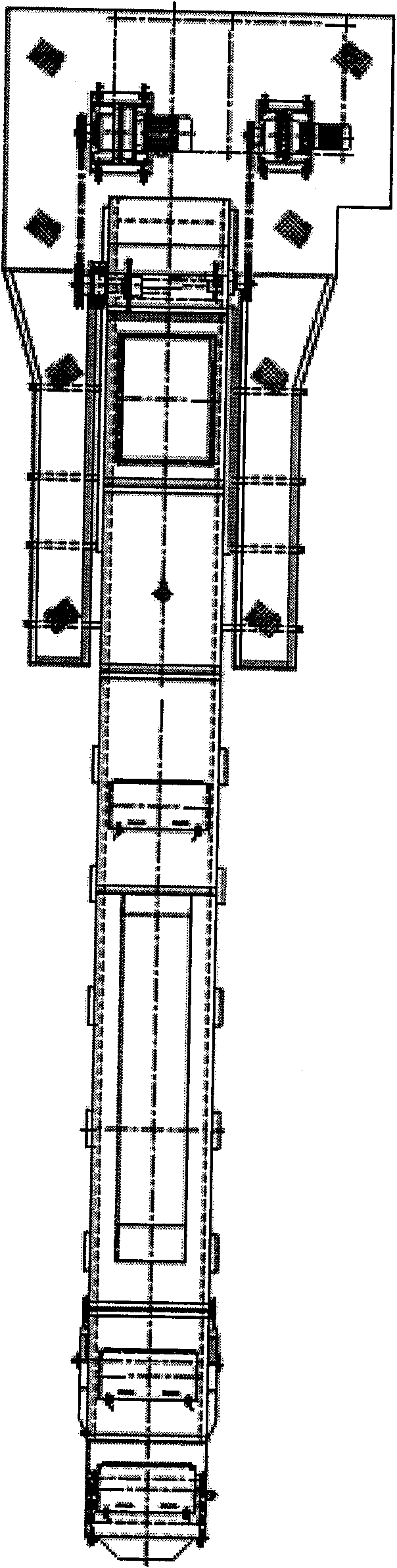

[0014] As shown in the figure, the conveyor is used to transport the slag processed by the drum to the slag discharge yard, and it is composed of a primary conveyor and a secondary conveyor. The primary conveyor is used to transport the slag processed by the drum to the secondary conveyor. It is composed of a scraper machine and a chain conveyor structure, fully enclosed, and the finished slag is cooled by a 120-degree nozzle inside the spray nozzle. With slag cleaning function. Conveyor shell and chain plate material: Q235 carbon steel. The secondary conveyor is used to transport the slag output by the primary conveyor to the finished slag stacking area, and a chain conveyor is used. Conveyor shell and chain plate material: Q235 carbon steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com