Method for processing waste water generated by water jet abrasives

A technology of water jet mill and wastewater treatment, which is applied in the direction of water/sewage multi-stage treatment, flotation water/sewage treatment, oxidized water/sewage treatment, etc. Suitable for industrial applications and other issues, to achieve the effect of low cost, simple and feasible treatment method, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

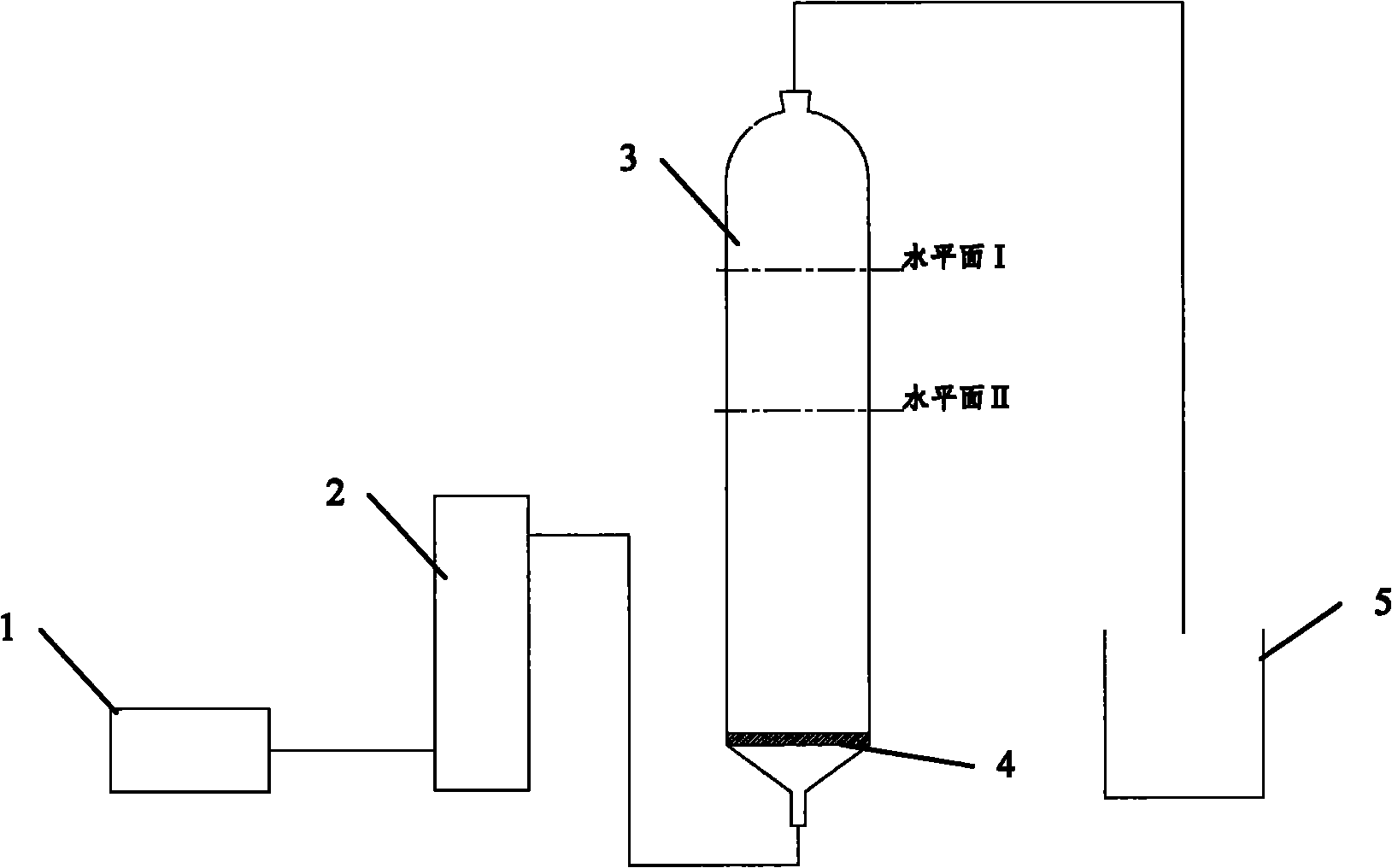

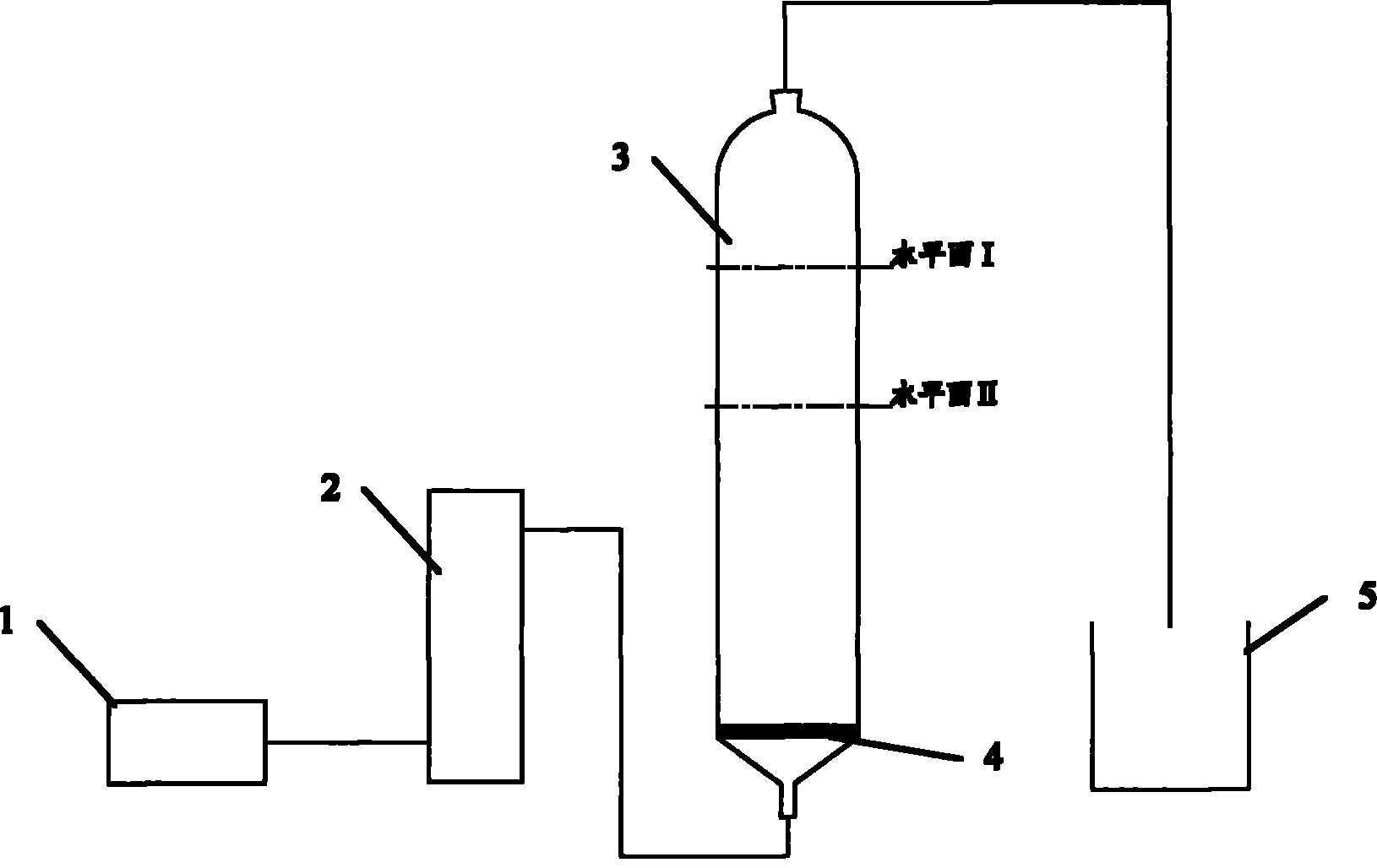

Method used

Image

Examples

Embodiment 1

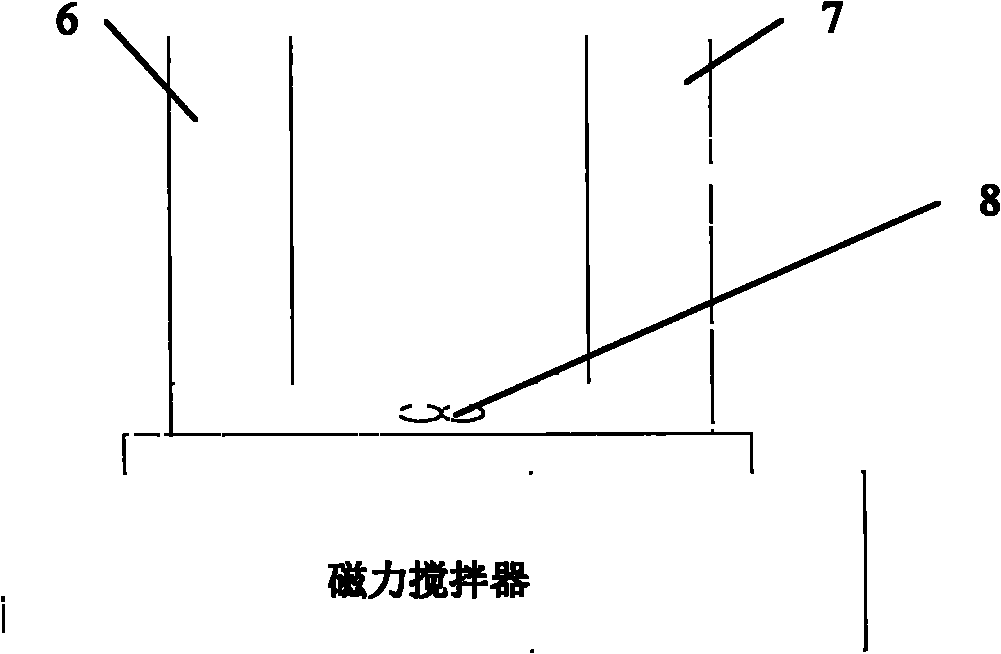

[0019] A) Recover part of PVA by electric flotation: first add 400mL of PVA-containing wastewater produced by water jet abrasives into the electrolytic cell equipped with a magnetic stirrer, and add electrolyte Na 2 SO 4 Start to stir afterward, make the concentration of electrolyte in waste water reach 0.05mol / L, regulate the voltage in the electrolyzer to 12V simultaneously, the froth scum that will produce in the stirring process is collected, and stirring time is 120min, wherein said electrolysis Both the anode and the cathode in the tank adopt graphite electrodes, and the distance between the anode and the cathode is controlled at 32 mm. The recovery rate of PVA was calculated to be 40.8%.

[0020] B) Use the Fenton oxidation method to treat the wastewater that has recovered part of the PVA by the electric float method: take 200ml of wastewater and place it in a container, adjust the pH value to 4 and stir, and then add H to the wastewater 2 o 2 and FeSO 4 ·7H 2 O, H...

Embodiment 2

[0022] A) Recover part of PVA by electric flotation: first add 400mL of PVA-containing wastewater produced by water jet abrasives into the electrolytic cell equipped with a magnetic stirrer, and add electrolyte Na 2 SO 4 Start to stir afterward, make the concentration of electrolyte in waste water reach 0.075mol / L, regulate the voltage in the electrolyzer to 10V simultaneously, the foam scum that will produce in the stirring process is collected, and stirring time is 150min, wherein said electrolysis Both the anode and the cathode in the tank adopt graphite electrodes, and the distance between the anode and the cathode is controlled at 32 mm. The recovery rate of PVA was calculated to be 43.2%.

[0023] B) Use the Fenton oxidation method to treat the wastewater that has recovered part of the PVA by the electric float method: take 200ml of wastewater and place it in a container, adjust the pH value to 4 and stir, and then add H to the wastewater 2 o 2 and FeSO 4 ·7H 2 O, H...

Embodiment 3

[0025] A) Recover part of PVA by electric flotation: first add 400mL of PVA-containing wastewater produced by water jet abrasives into the electrolytic cell equipped with a magnetic stirrer, and add electrolyte Na 2 SO 4 Start to stir afterward, make the concentration of electrolyte in waste water reach 0.1mol / L, regulate the voltage in the electrolyzer to 12V simultaneously, the foam scum that will produce in the stirring process is collected, and stirring time is 240min, wherein said electrolysis Both the anode and the cathode in the tank adopt graphite electrodes, and the distance between the anode and the cathode is controlled at 32mm. The recovery rate of PVA was calculated to be 52.3%.

[0026] B) Use the Fenton oxidation method to treat the wastewater that has recovered part of the PVA by the electric float method: take 200ml of wastewater and place it in a container, adjust the pH value to 4 and stir, and then add H to the wastewater 2 o 2 and FeSO 4 ·7H 2 O, H 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com