Chlor-alkali wastewater treatment method

A wastewater treatment, chlor-alkali technology, applied in water/sewage treatment, water treatment parameter control, neutralized water/sewage treatment, etc., can solve the problems of waste, inability to recover chloride ions, high treatment cost, and achieve low cost and treatment methods. Simple and actionable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

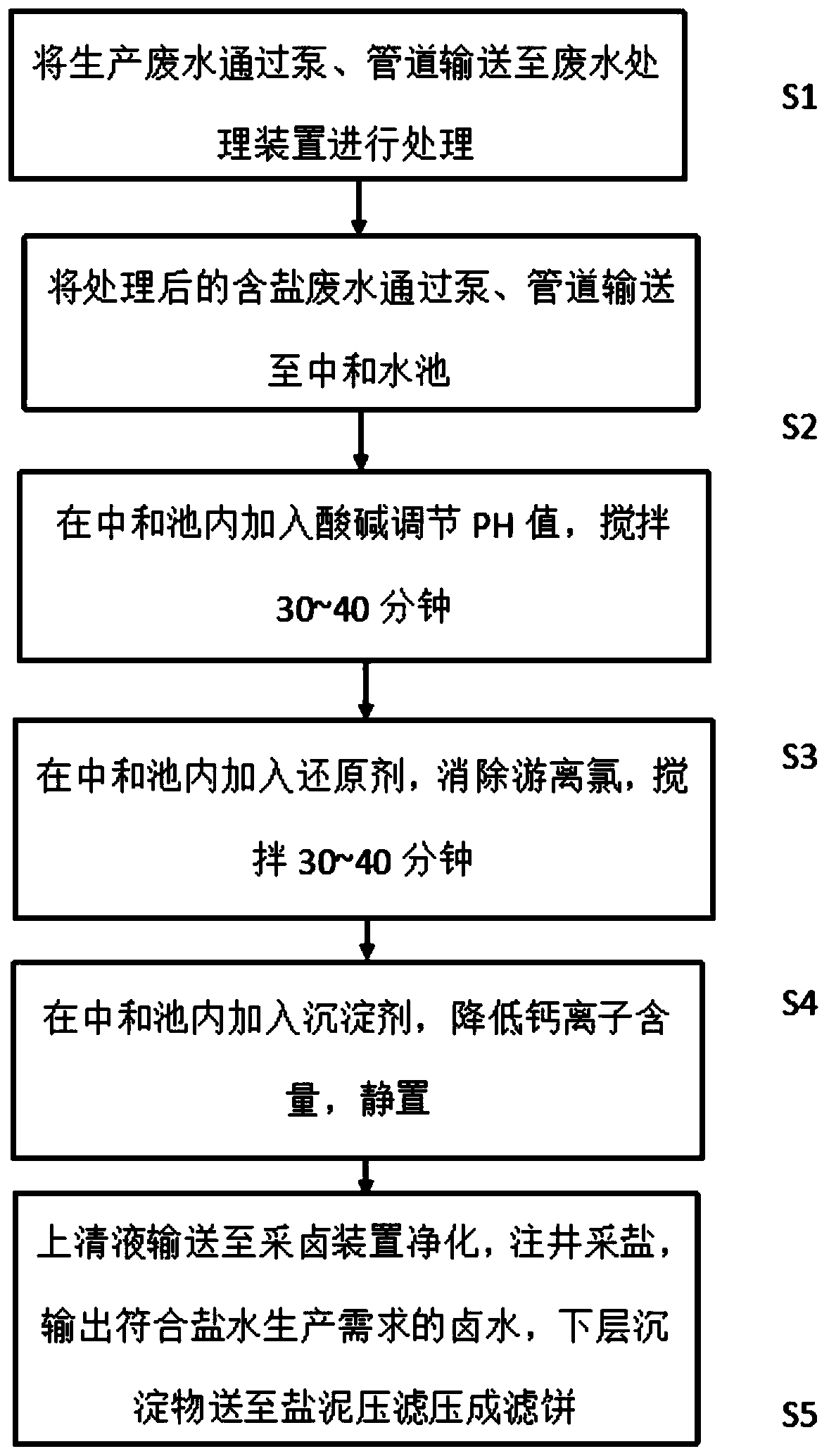

Image

Examples

Embodiment 1

[0033] A method for treating chlor-alkali wastewater, specifically: transporting chlor-alkali wastewater to a wastewater treatment device to perform "ultrafiltration + nanofiltration membrane" treatment to eliminate organic matter, and obtain concentrated water and saline wastewater after treatment, and the saline wastewater contains free chlorine , excessive calcium ions, recover the desulfurization water from the concentrated water, and transport the saline wastewater to the neutralization tank; add hydrochloric acid, adjust the pH value of the saline wastewater to 9, and stir for 35 minutes; add sodium sulfite, sodium sulfite and The free chlorine in the salty wastewater undergoes oxidation-reduction reaction to remove chlorine, and stir for 30 minutes; add sodium carbonate to the neutralization tank, and the sodium carbonate and calcium ions in the saline wastewater undergo a precipitation reaction. After standing for 2 hours, the neutralization tank The saline wastewater i...

Embodiment 2

[0035] A method for treating chlor-alkali wastewater, specifically: transporting chlor-alkali wastewater to a wastewater treatment device to perform "ultrafiltration + nanofiltration membrane" treatment to eliminate organic matter, and obtain concentrated water and saline wastewater after treatment, and the saline wastewater contains free chlorine , excessive calcium ions, recover the desulfurization water from the concentrated water, and transport the saline wastewater to the neutralization tank; add hydrochloric acid, adjust the pH value of the saline wastewater to 8, and stir for 40 minutes; add sodium sulfite, sodium sulfite and sodium sulfite to the neutralization tank The free chlorine in the salty wastewater undergoes oxidation-reduction reaction to remove chlorine, and stir for 40 minutes; add sodium carbonate to the neutralization tank, and the sodium carbonate and calcium ions in the saline wastewater undergo a precipitation reaction. After standing for 2.5 hours, the ...

Embodiment 3

[0037] A method for treating chlor-alkali wastewater, specifically: transporting chlor-alkali wastewater to a wastewater treatment device to perform "ultrafiltration + nanofiltration membrane" treatment to eliminate organic matter, and obtain concentrated water and saline wastewater after treatment, and the saline wastewater contains free chlorine , excessive calcium ions, recover the desulfurization water from the concentrated water, and transport the saline wastewater to the neutralization tank; add caustic soda, adjust the pH value of the saline wastewater to 7, and stir for 30 minutes; add sodium sulfite, sodium sulfite and sodium sulfite to the neutralization tank The free chlorine in the salty wastewater undergoes oxidation-reduction reaction to remove chlorine, and stir for 35 minutes; add sodium carbonate to the neutralization tank, and the sodium carbonate and calcium ions in the salty wastewater undergo precipitation reaction, and after standing for 3 hours, the neutra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com