Pearlite ceramsite composite acoustic board

A technology of perlite and sound-absorbing panels, which is applied in noise-absorbing devices and buildings, can solve the problems of high maintenance costs, light resistance, aging resistance, unsuitable color control, and heavy inorganic materials, etc., so as to improve the integrity rate of finished products, Low product cost and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

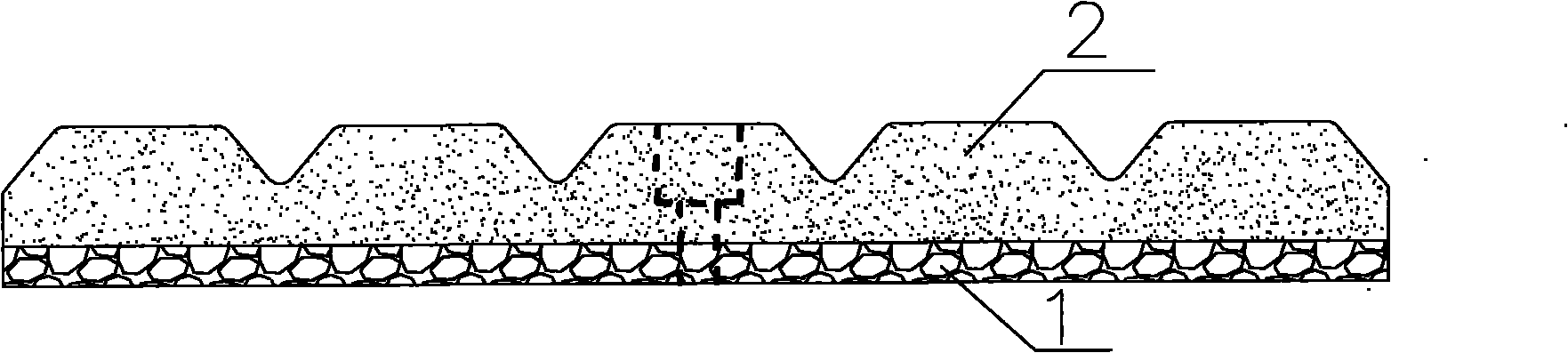

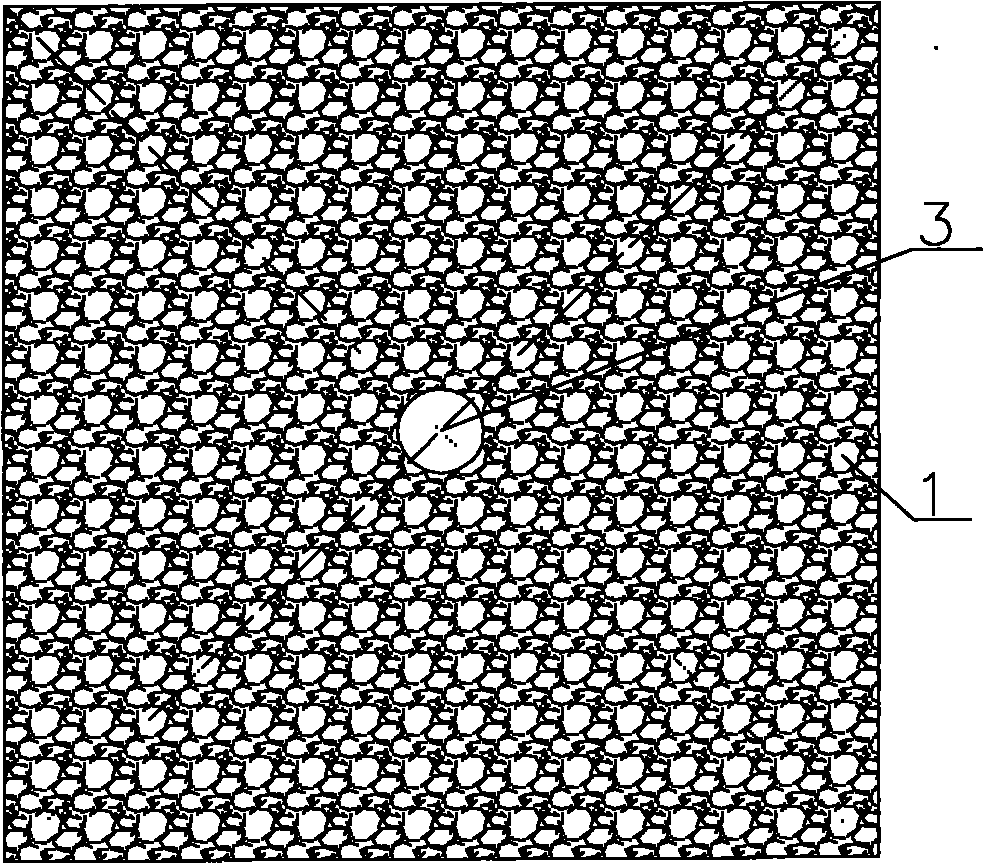

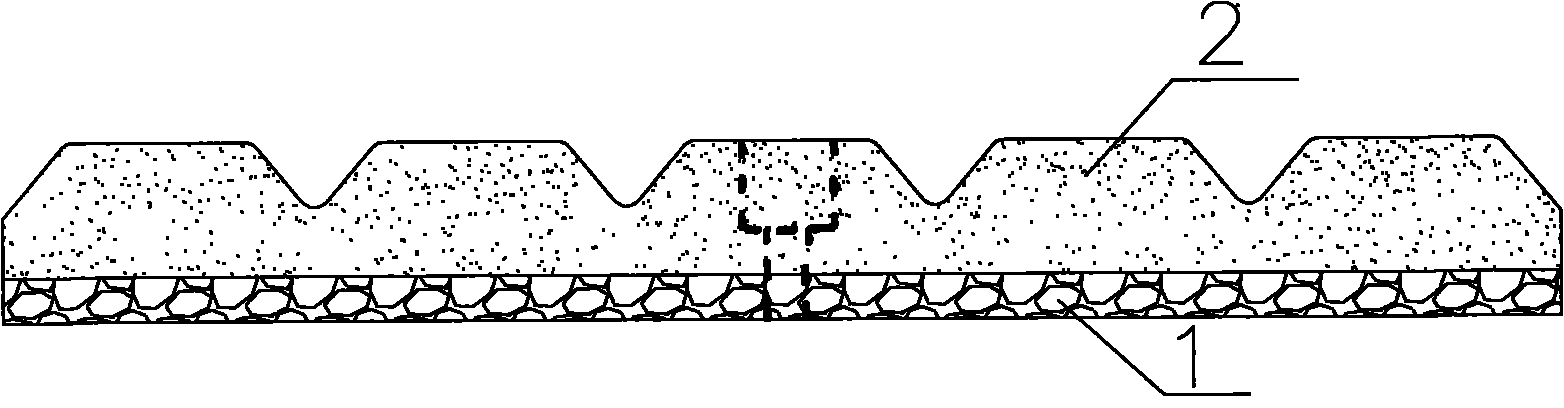

[0019] A perlite ceramsite composite sound-absorbing board includes closely connected ceramsite layer lightweight concrete 1 and perlite sound-absorbing material 2 , the perlite sound-absorbing material 2 is on top, and the ceramsite layer lightweight concrete 1 is on the bottom.

[0020] The perlite ceramsite composite sound-absorbing panel is based on the principle of material compounding, and the ceramsite layer lightweight concrete 1 and perlite sound-absorbing material 2 are added to the mold in turn, layered and formed at one time, and the two materials are bonded through concrete by using external pressure force and the occlusal force between the uneven transition surfaces; the external pressure is not less than 3kMPa, so that the pre-compressed / post-compressed thickness ratio of perlite compression deformation is 1.25-1.35, and the pre-compres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com