Wind magnet comprehensive generating system

A technology of power generation system and wind power generation device, which is applied in the direction of wind power engine, wind power motor combination, generator/motor, etc. It can solve the problems of no speed, increase of negative resistance, high cost, etc., and achieve the reduction of overall size and rotation resistance , Increase the effect of working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

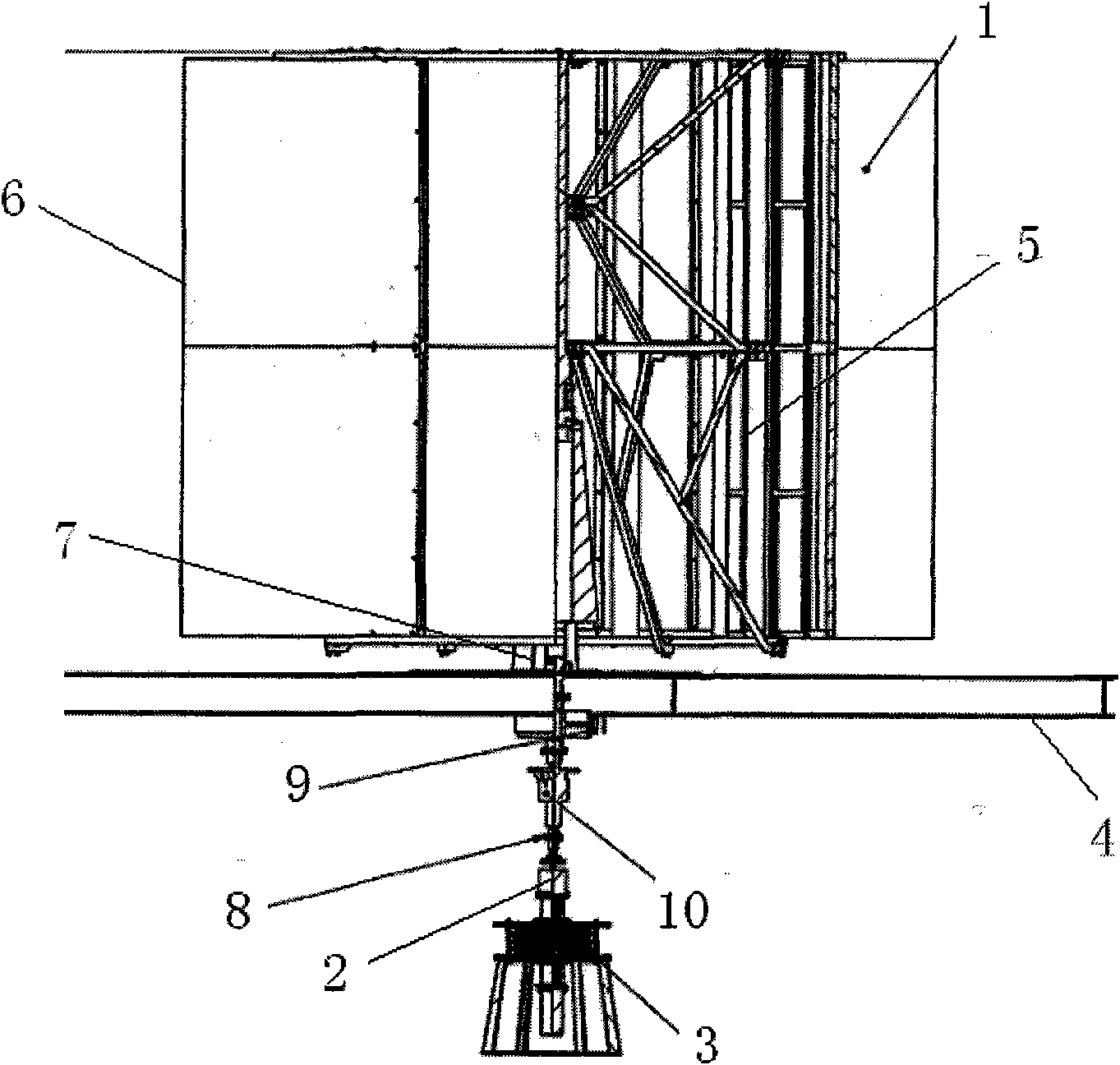

[0022] like figure 1 As shown, the present invention includes a wind power generator 1 , a generator 2 and a magnetodynamic generator 3 .

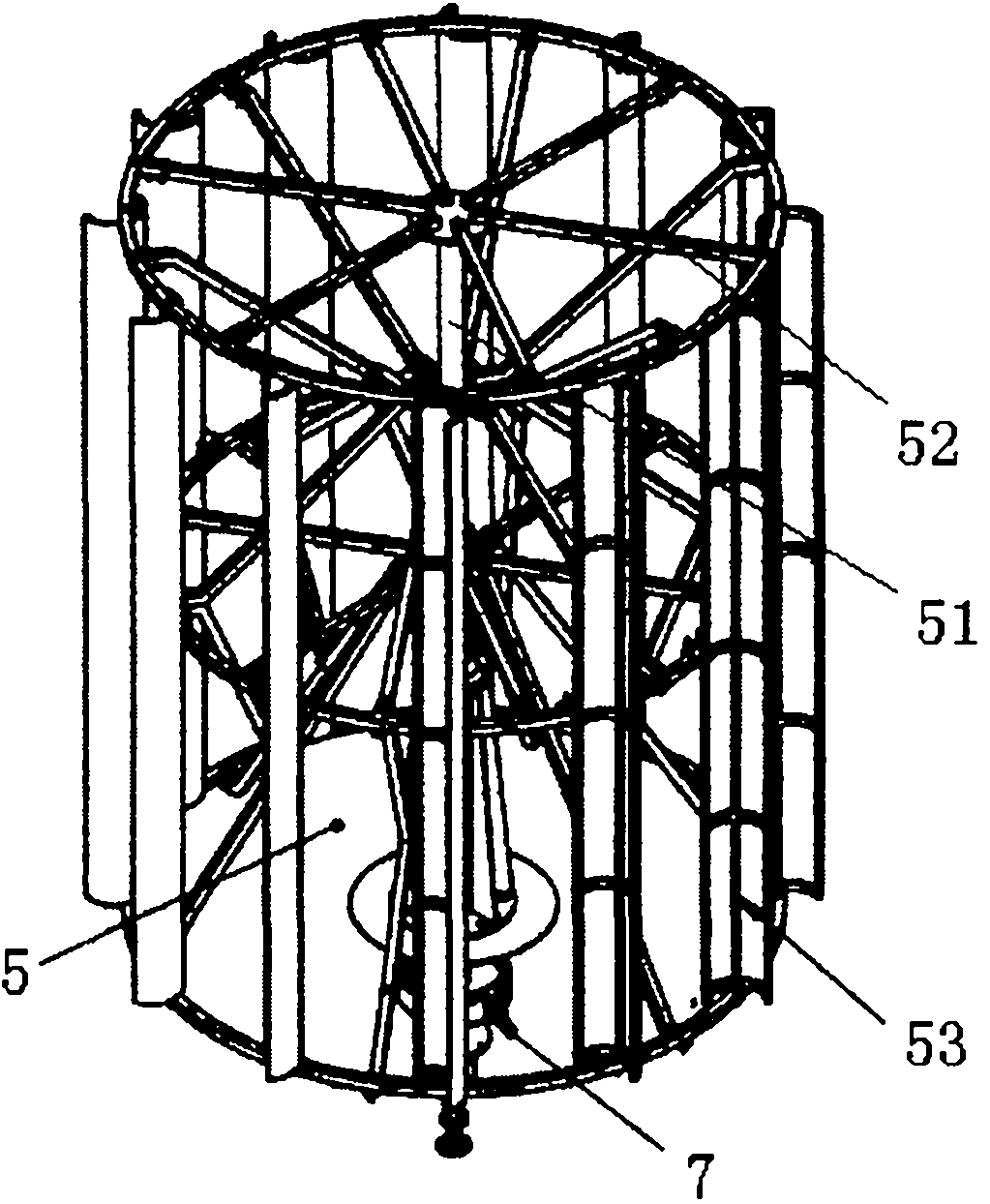

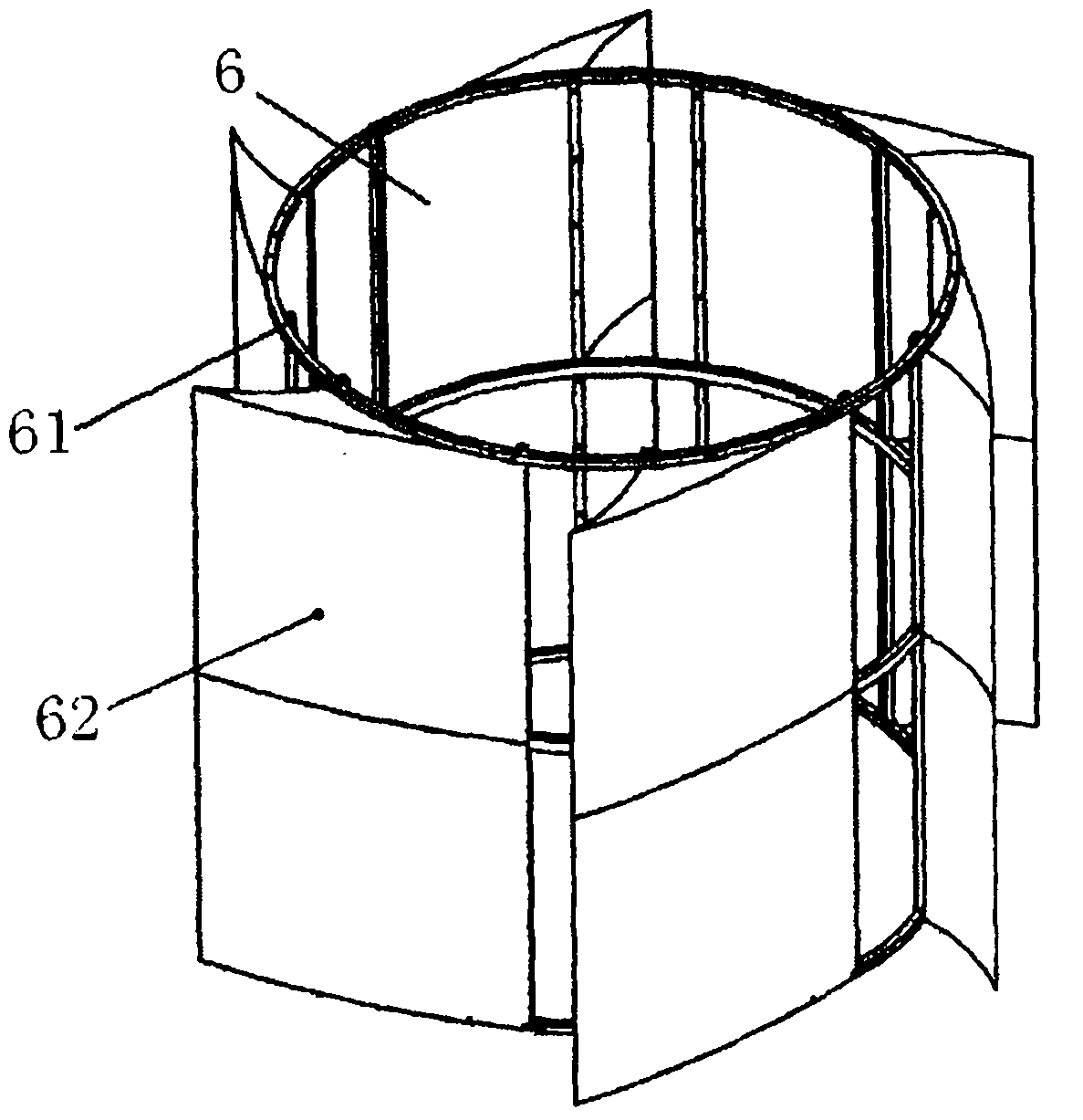

[0023] like figure 1 , figure 2 As shown, the wind power generation device 1 is arranged above the roof platform 4, and it includes a rotating wind wheel 5. The rotating wind wheel 5 includes a vertical main shaft 51, and the vertical main shaft 51 is provided with a circle of supporting frames 52 in the circumferential direction. Several fan blades 53 are provided. like figure 1 , image 3 , Figure 4 As shown, the periphery of the rotating wind wheel 5 is provided with a wind searching device 6 fixed on the roof installation platform 4, and the wind searching device 6 includes a wind searching barrel frame 61 in which the rotating wind wheel 5 can be installed, and the wind searching barrel frame 61 Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com