Photonic crystal fiber optic liquid level sensor and sensing system formed by same

A technology of photonic crystal optical fiber and liquid level sensor, which is applied in the direction of cladding optical fiber, optical waveguide, liquid level indicator, etc., and can solve problems such as limited use, reduced mechanical strength of optical fiber, and temperature cross-sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

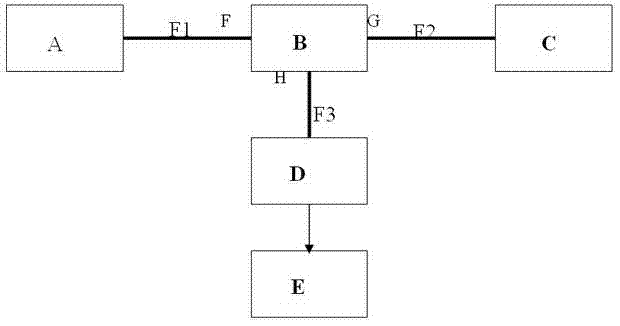

[0079] The implementation of the above-mentioned sensor and system will be described below by taking the measurement of the liquid level of salad oil as an example in conjunction with the accompanying drawings. The liquid level measurement method of other liquids whose refractive index is larger than that of the photonic crystal fiber cladding is the same, the difference is that the sensitivity of liquid level sensing of different refractive indices is different.

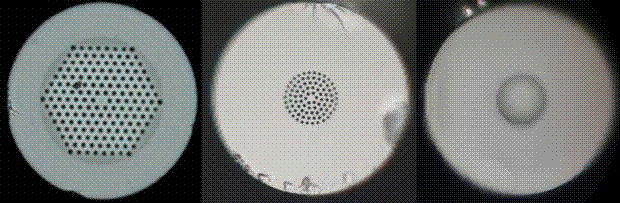

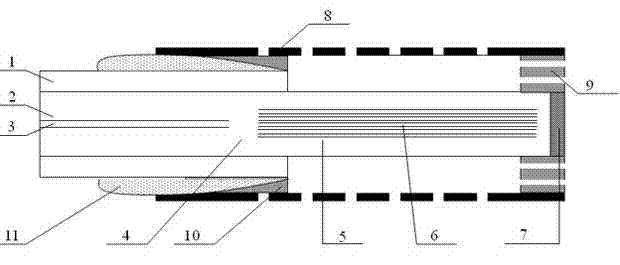

[0080] A photonic crystal fiber liquid level sensor is characterized in that it comprises a single-mode fiber SMF-28 and a photonic crystal fiber SC-4.0, the beginning of the single-mode fiber SMF-28 and the photonic crystal fiber SC-4.0 are fused, and the photonic crystal fiber The cladding air hole at the beginning of the fusion splicing point is closed to form a completely collapsed region of the fusion point; the end of the photonic crystal fiber is discharged by a fusion splicer to form a terminal collapsed regi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com