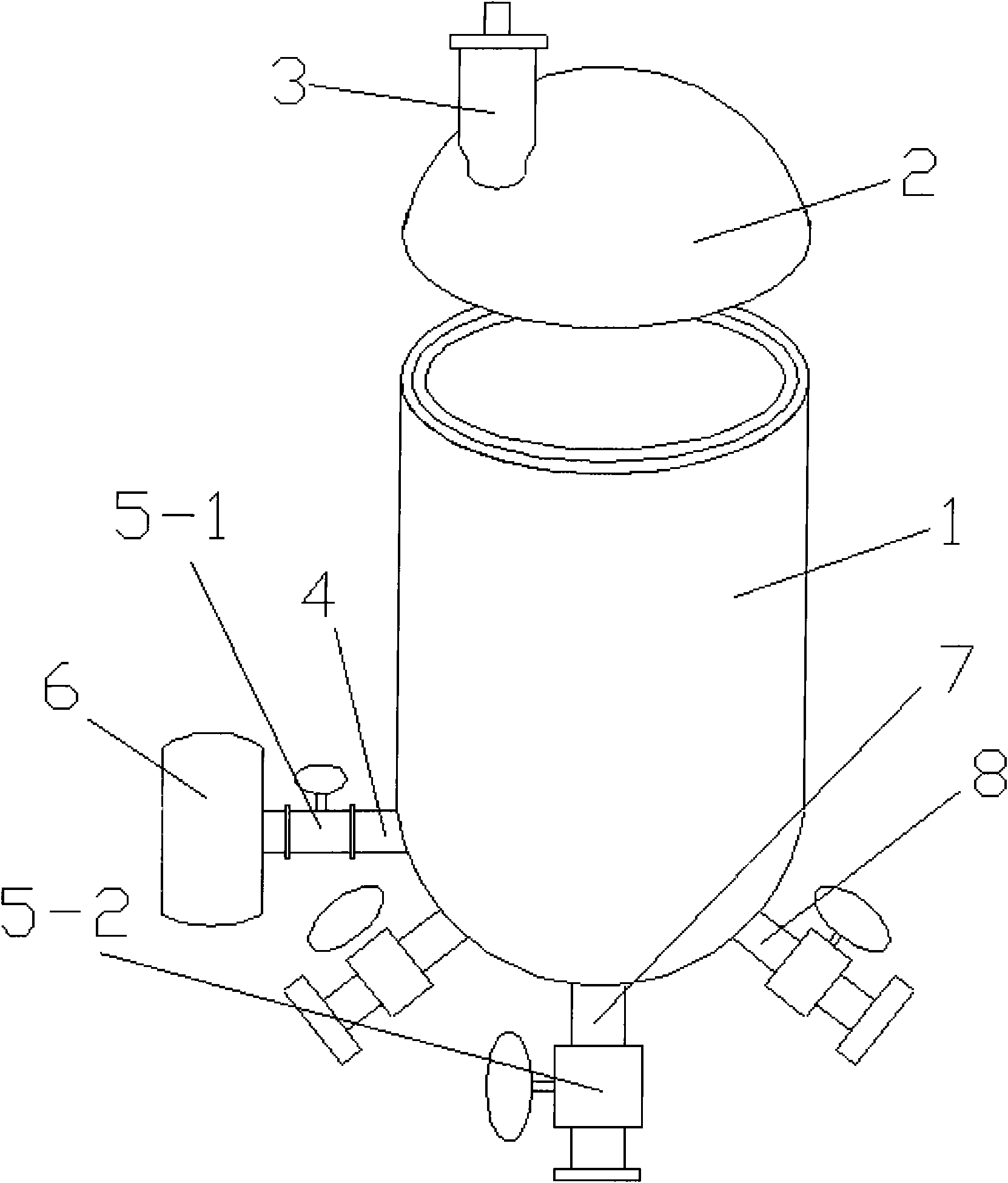

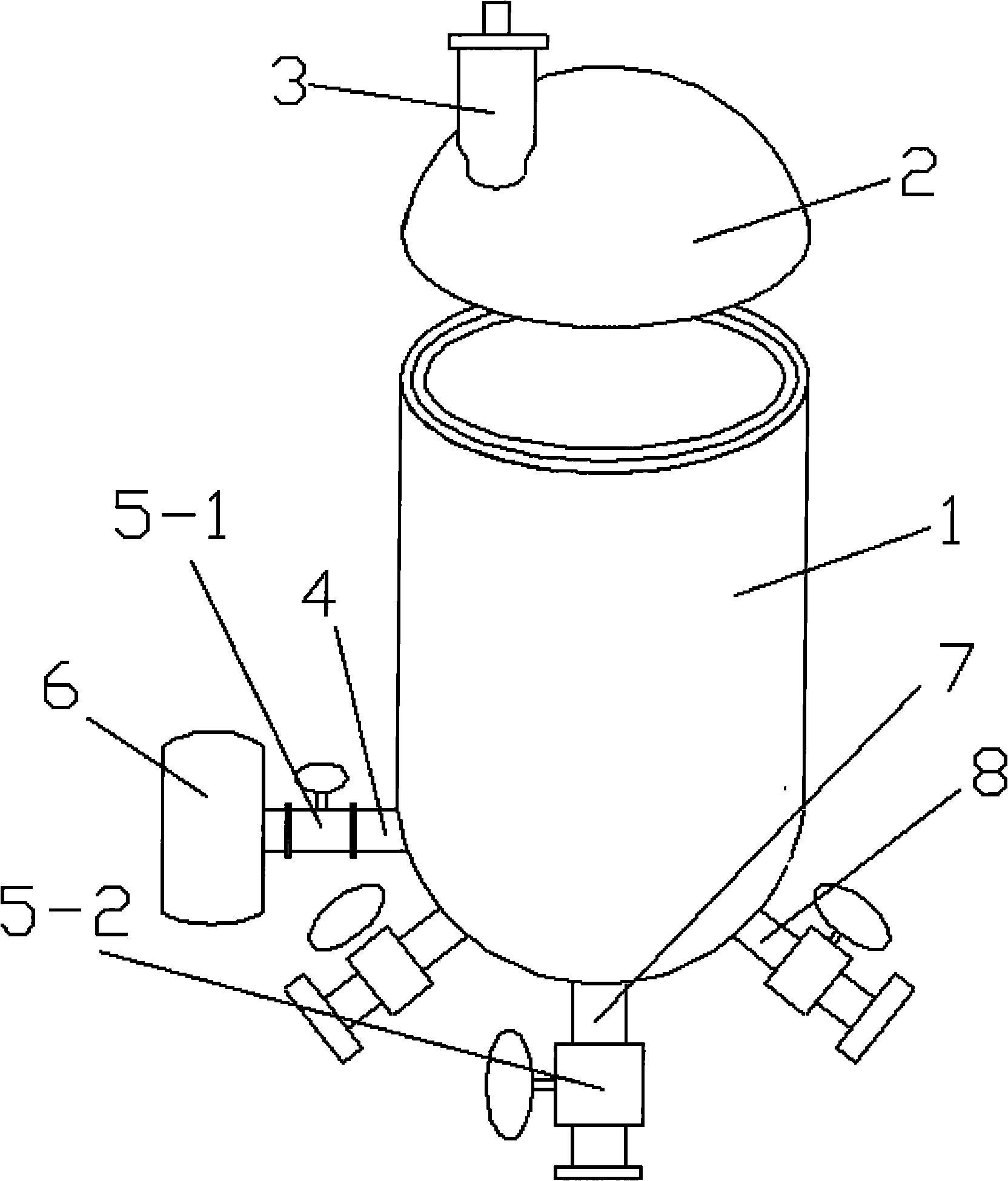

Double-layer double-safety autoclave with discharge pipe orifices

A high-pressure reactor and double-safety technology, which is applied in the field of double-layer double-safety high-pressure reactors, can solve problems such as explosions, different reactant rates, and higher requirements for reactor sealing, and achieve enhanced safety, simple structure, and enhanced strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Such as figure 1 shown. A double-layer double-safety high-pressure reaction kettle with a discharge nozzle, including a kettle body 1, a kettle cover 2, and the kettle body 1 and the kettle cover 2 are all connected by double-layer steel plates through explosive welding. An explosion-proof valve 3 is installed, a pressure relief nozzle 4 is provided on the side of the kettle body 1, a valve 5-1 is installed on the pressure relief nozzle 4, a pressure relief storage tank 6 is arranged outside the kettle body 1, and the pressure relief storage tank 6 enters The gas port communicates with the pressure relief nozzle 4 at the bottom of the kettle body 1 through the valve 5-1. A vertical straight pipe discharge nozzle 7 is arranged in the middle of the bottom of the kettle body 1, and the kettle body next to the straight pipe discharge nozzle 7 1. The bottom is also inclined to be provided with an inclined discharge nozzle 8, and a valve 5-2 is respectively installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com