Code dividing machine for grabbing and counting plastic glove

A glove and digital technology, which is applied in the field of plastic glove grasping and counting digital extensions, can solve problems such as unguaranteed quality, uneven placement, and prone to mistakes, and achieve high grasping efficiency, automation, and accurate grasping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

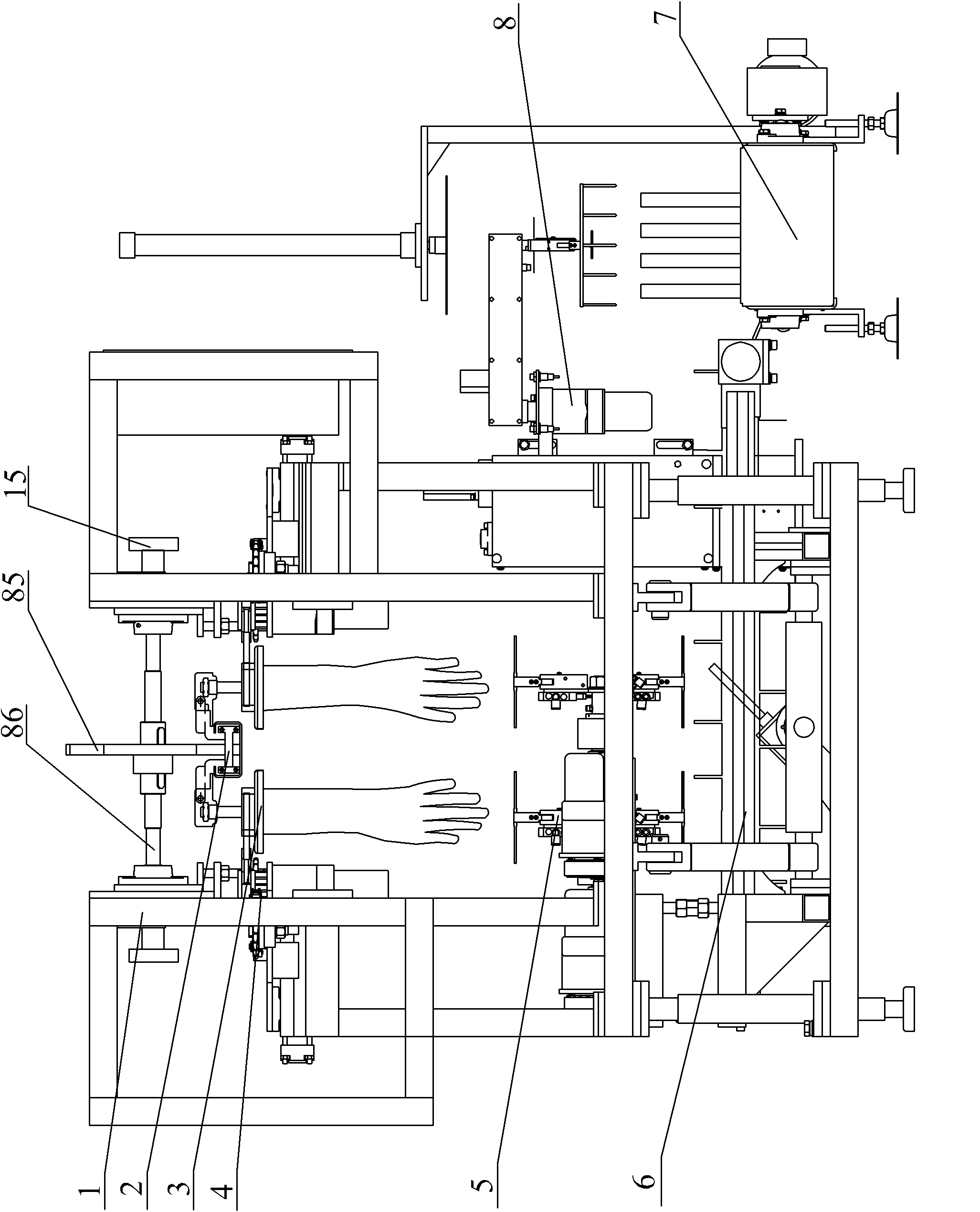

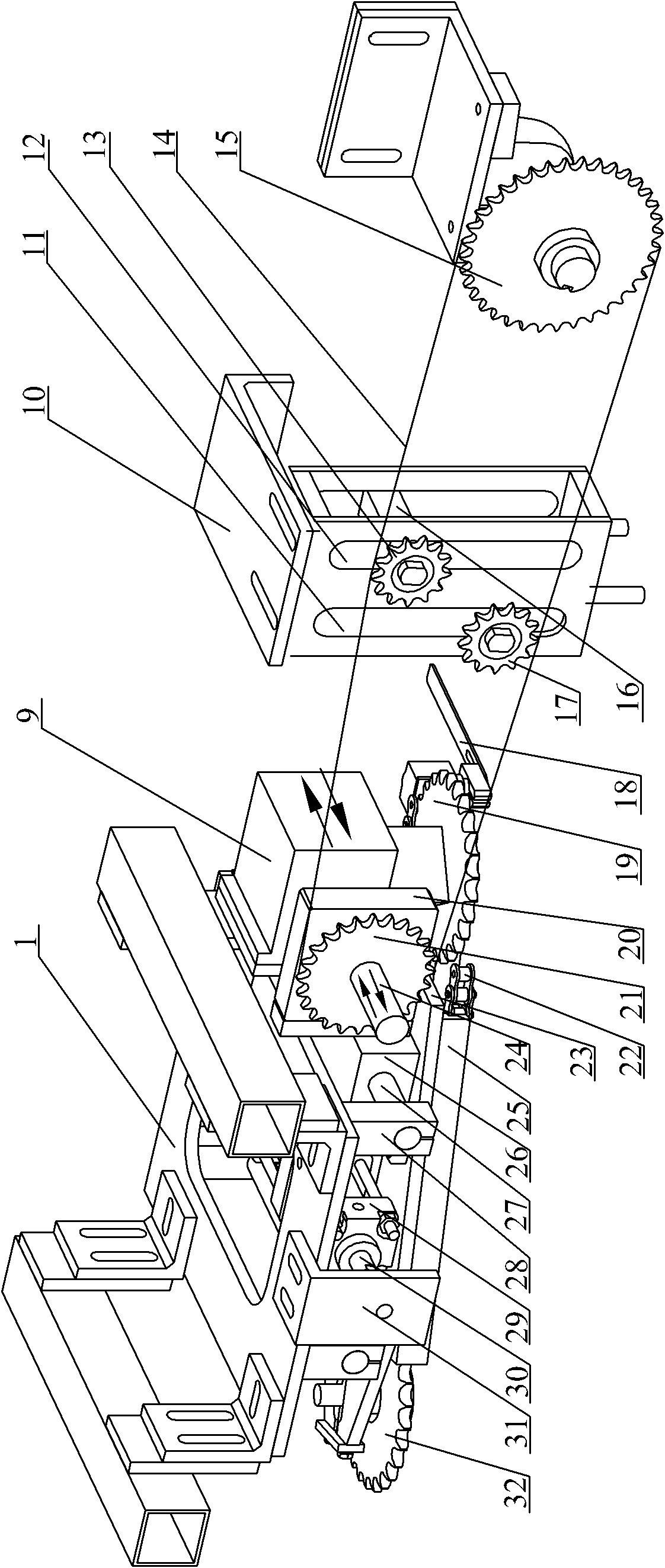

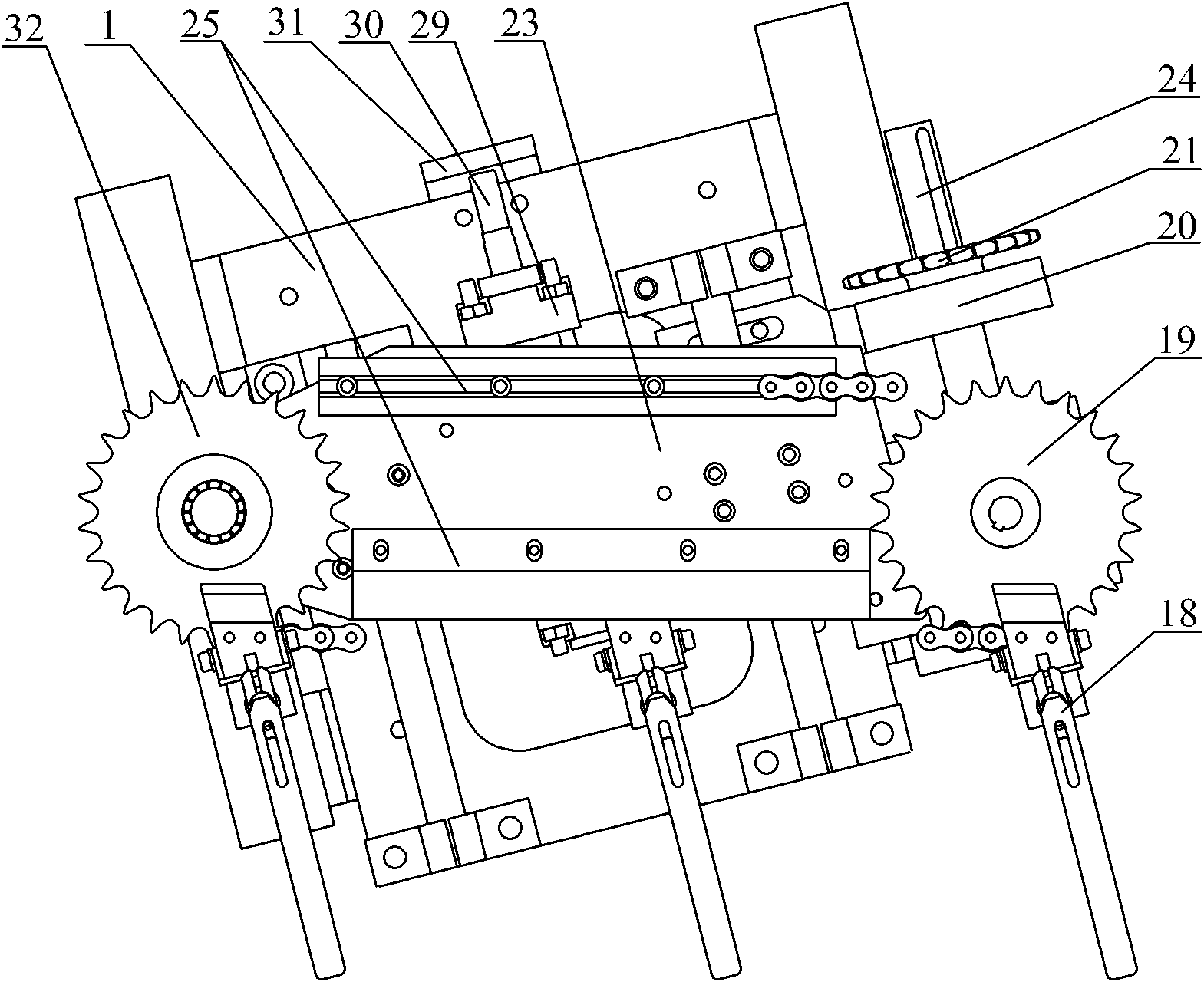

[0035] Such as figure 1 As shown, the plastic glove grasping counter digital extension includes a bracket 1, a symmetrical double-sided mold line 2 and a glove grabbing device 5, a symmetrical double-sided mold line 2 is set in the bracket 1, and a symmetrical double-sided mold line 2 is installed with a hand mold 3, and the glove grabbing device 5 is correspondingly arranged under the symmetrical double-sided hanging mold line 2. The glove grabbing device 5 is corresponding to one end of the conveying line 6, and the other end of the conveying line 6 is provided with a fishing and transferring device 8. Gloves An optical switch is installed in the grabbing device 5 , and a glove box line 7 is set in front of the grabbing transfer device 8 .

[0036] Both sides of the symmetrical double-sided die-hanging line 2 are provided with a hand model correction device 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com