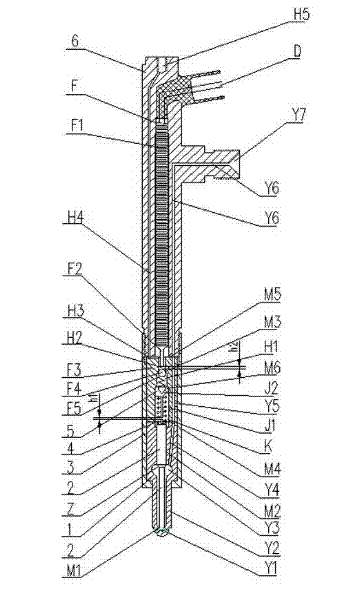

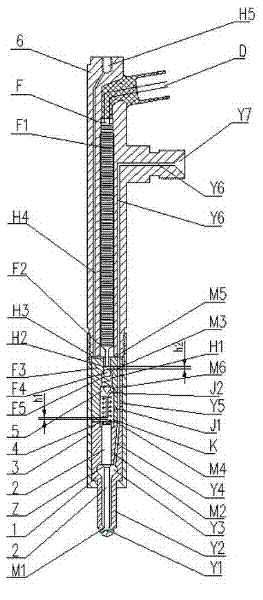

Piezoelectric high-pressure common rail electronic control injector

A high-pressure common rail and electronically controlled fuel injection technology, which is applied in the direction of machines/engines, fuel injection devices, engine components, etc., can solve problems such as poor injection performance and complex structure, and achieve fewer parts, faster response, and reduced The effect of fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Such as figure 1 The shown piezoelectric high-pressure common rail electronically controlled fuel injector of the present invention includes a needle valve body 1, a needle valve 2, a fastening nut 3, a fuel injector body 6, and a piezoelectric crystal two-way valve F, piezoelectric crystal two-way valve F includes piezoelectric crystal actuator F1, piezoelectric actuator push rod F2, valve seat F3, valve F4, spring F5, spring seat 5, piezoelectric crystal actuator F1 and its lower end connection The integrated actuator push rod F2 is installed in the cylindrical hole of the injector body 6, the upper end of the piezoelectric crystal actuator F1 is tightly fitted with the cylindrical hole, and the lower part is slidingly fitted with the cylindrical hole; the valve F4 is installed in the valve seat F3 , spring F5, needle valve spring 4, spring seat 5, the needle valve 2 is installed in the needle valve body 1, the outer cylindrical surface of the upper part of the needle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com