Method for manufacturing LED illumination module with disinfection function

A technology of LED lighting and manufacturing methods, which is applied to the parts of lighting devices, cooling/heating devices of lighting devices, disinfection, etc., can solve problems such as eye and skin damage, environmental pollution, etc., achieve convenient sterilization and disinfection, reduce costs, The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, the present invention is described in further detail with embodiment:

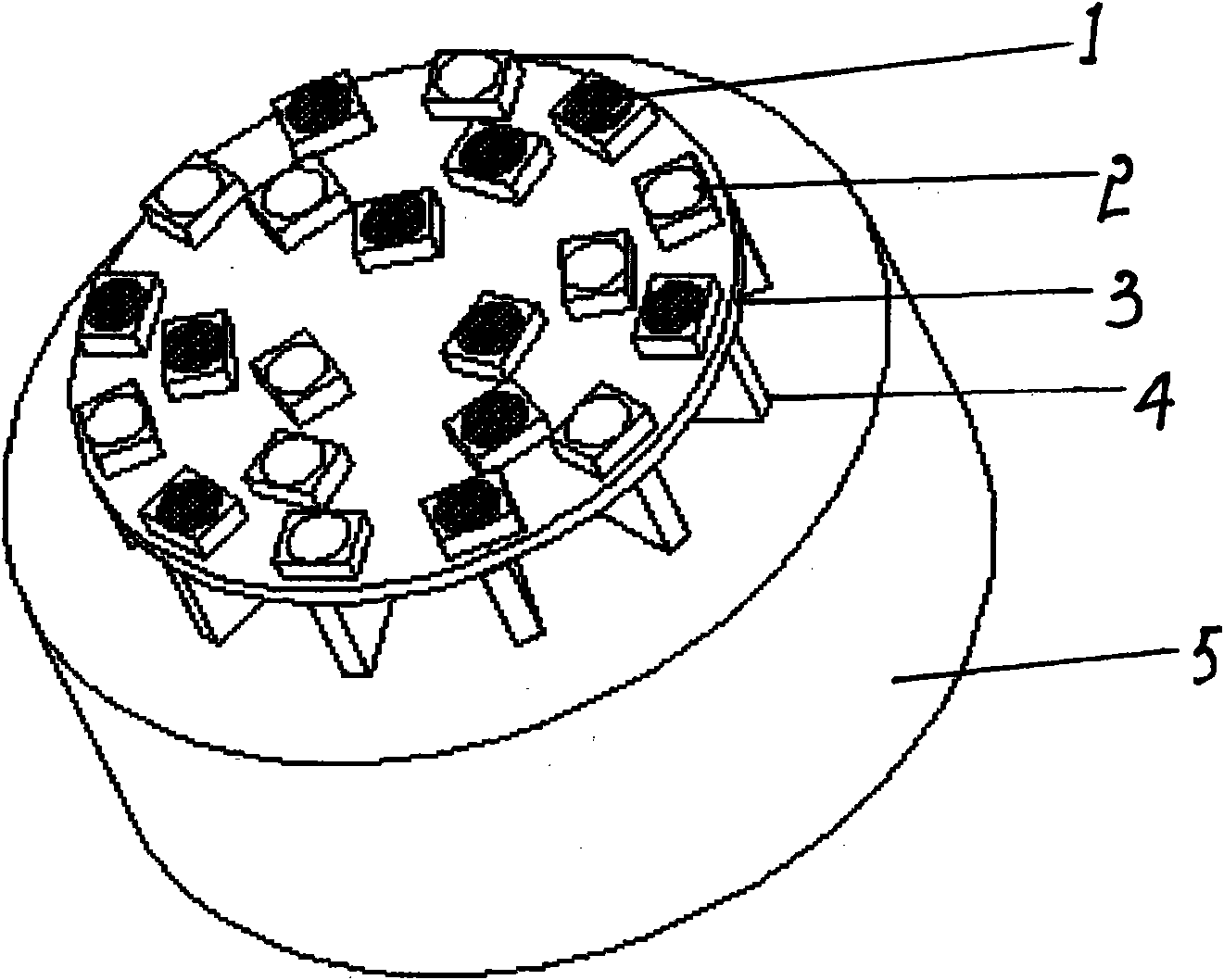

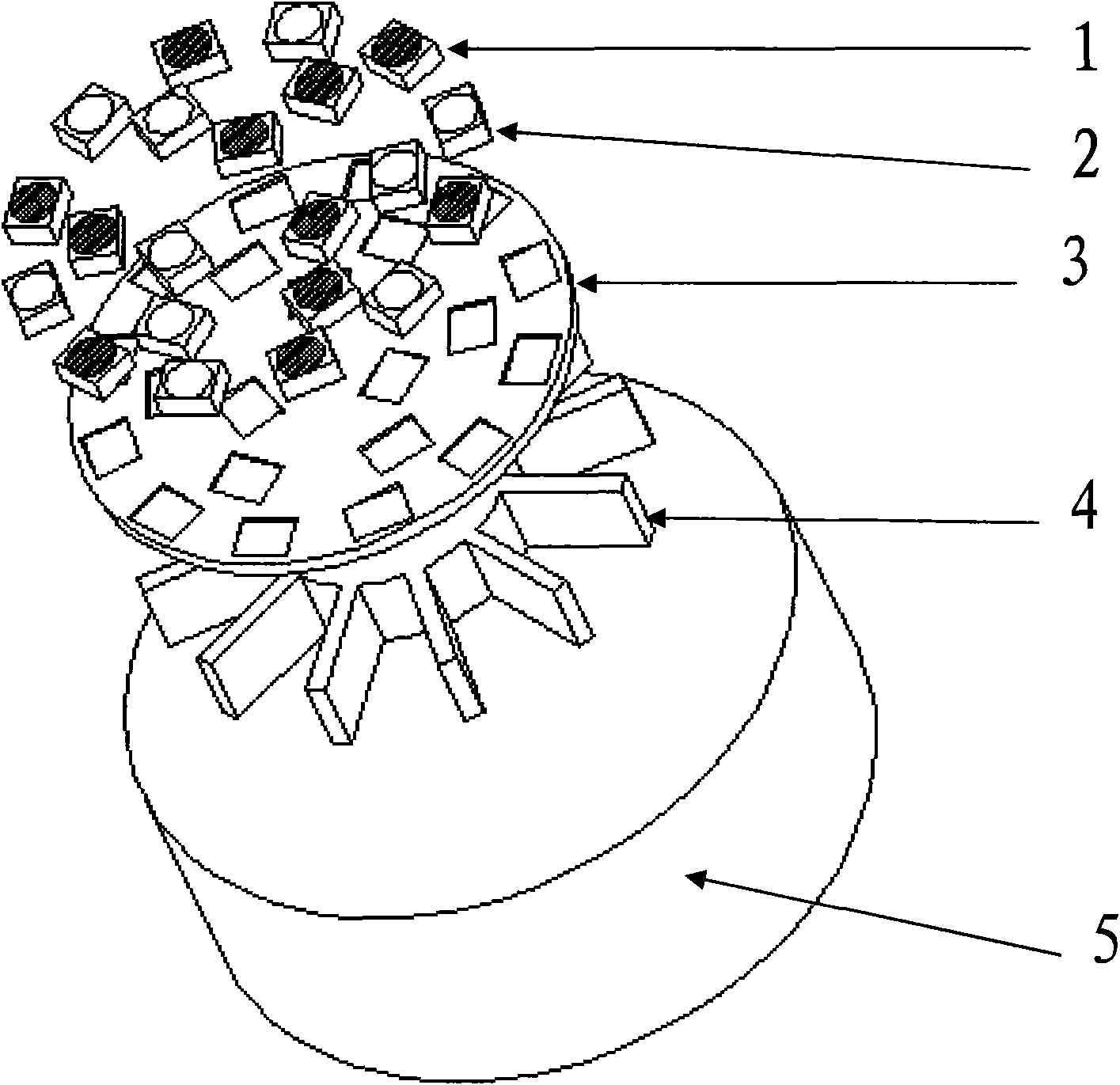

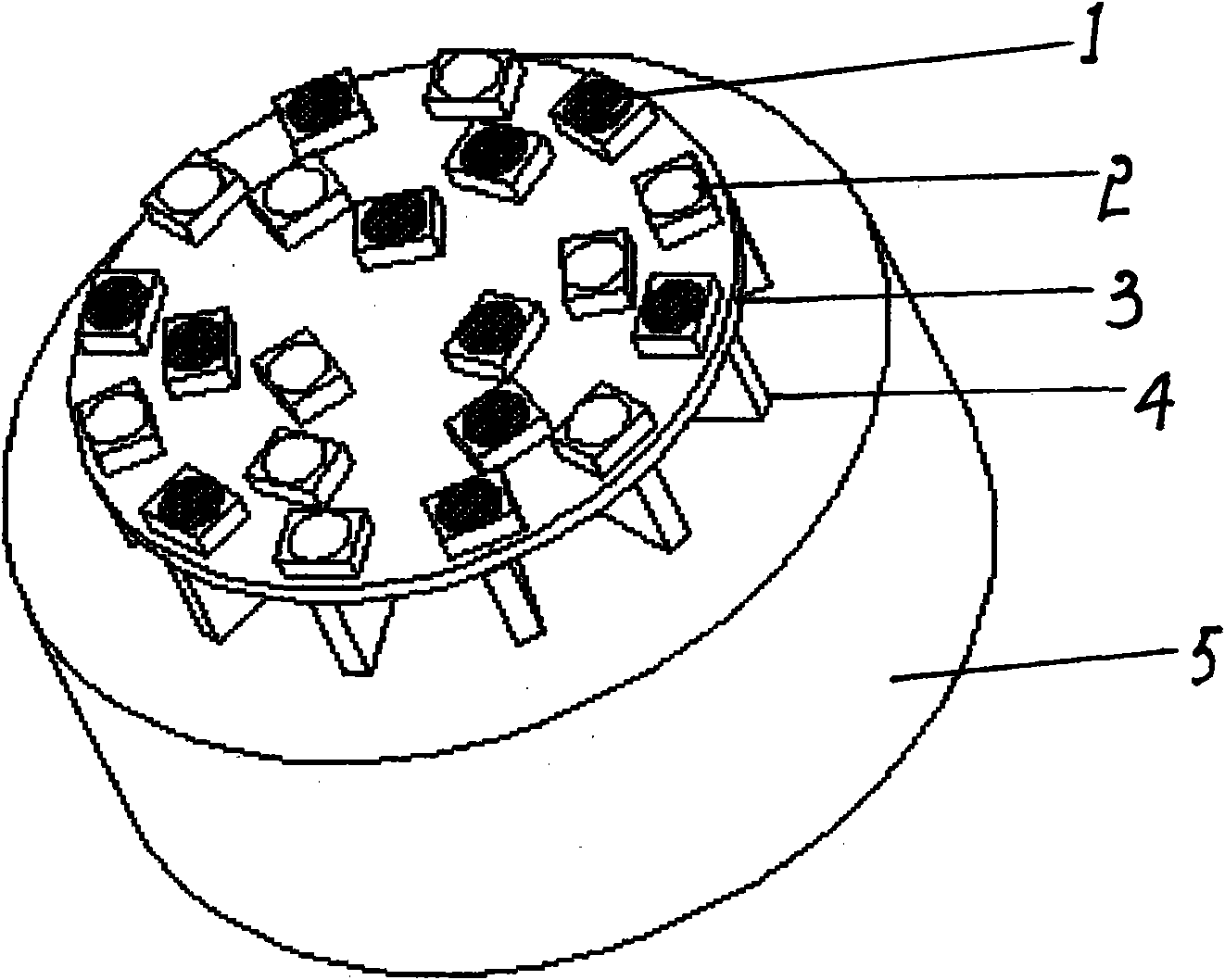

[0010] Fix the white light LED (1) and the ultraviolet LED (2) on the circuit board (3) in a way that they are evenly mixed with each other, and set a radiator (4) to ensure that the module is in the lighting state or sterilization The light emitted by the sterilized state is uniform enough; then the mold is assembled on the occasion of use.

[0011] Take the refrigerator as an example: the module composed of white LED (1) and ultraviolet LED (2) is assembled in the original lighting fixture, and a cycle switching power supply with light control, infrared induction, time control and other functions is assembled. The modules (5) are mounted in place. When the refrigerator door is opened, a cycle switching power supply module (5) with functions such as light control, infrared sensing, and time control will sense the action of opening the door, and at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com