Drying passage for external tile roller kiln

A drying and passage technology, applied in the kiln field, can solve the problems of difficult handling in the subsequent process, messy bricks, and uneven running of bricks, and achieve the effects of reducing management costs and labor costs, increasing production, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

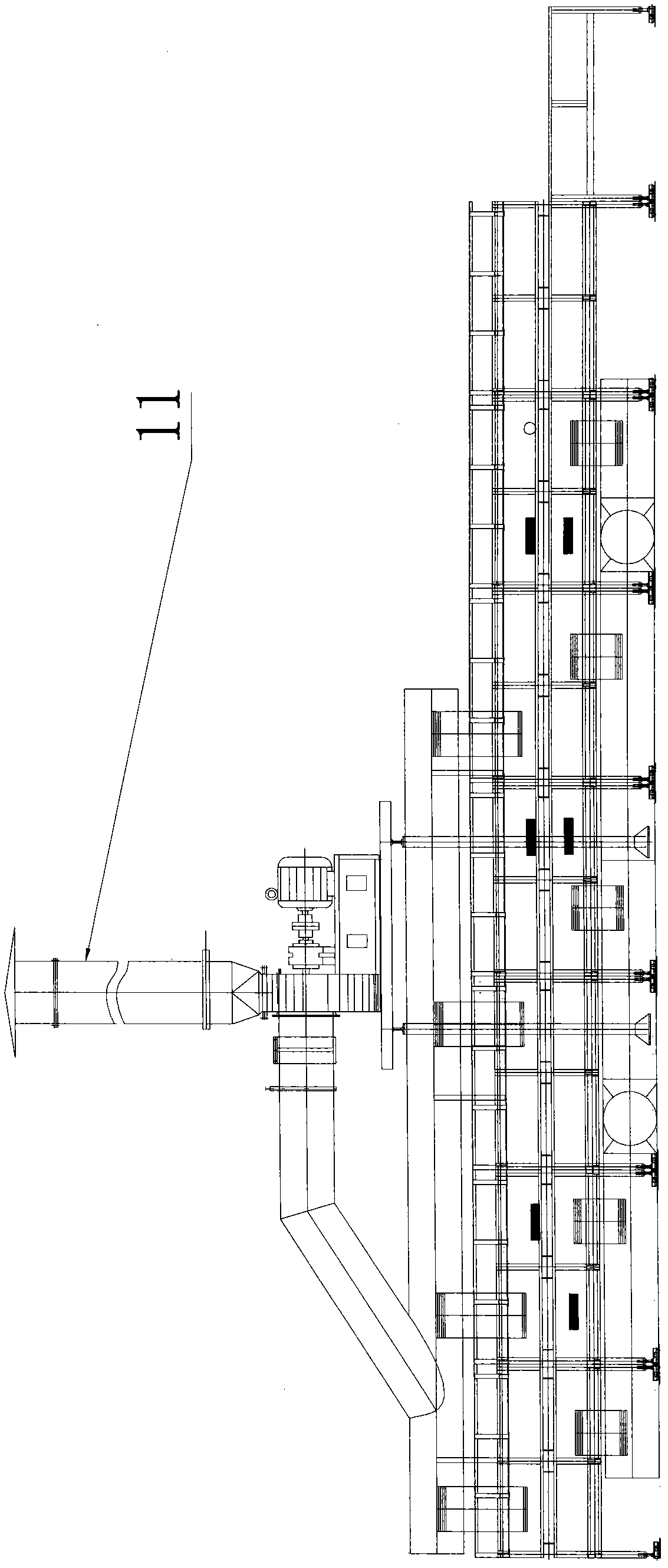

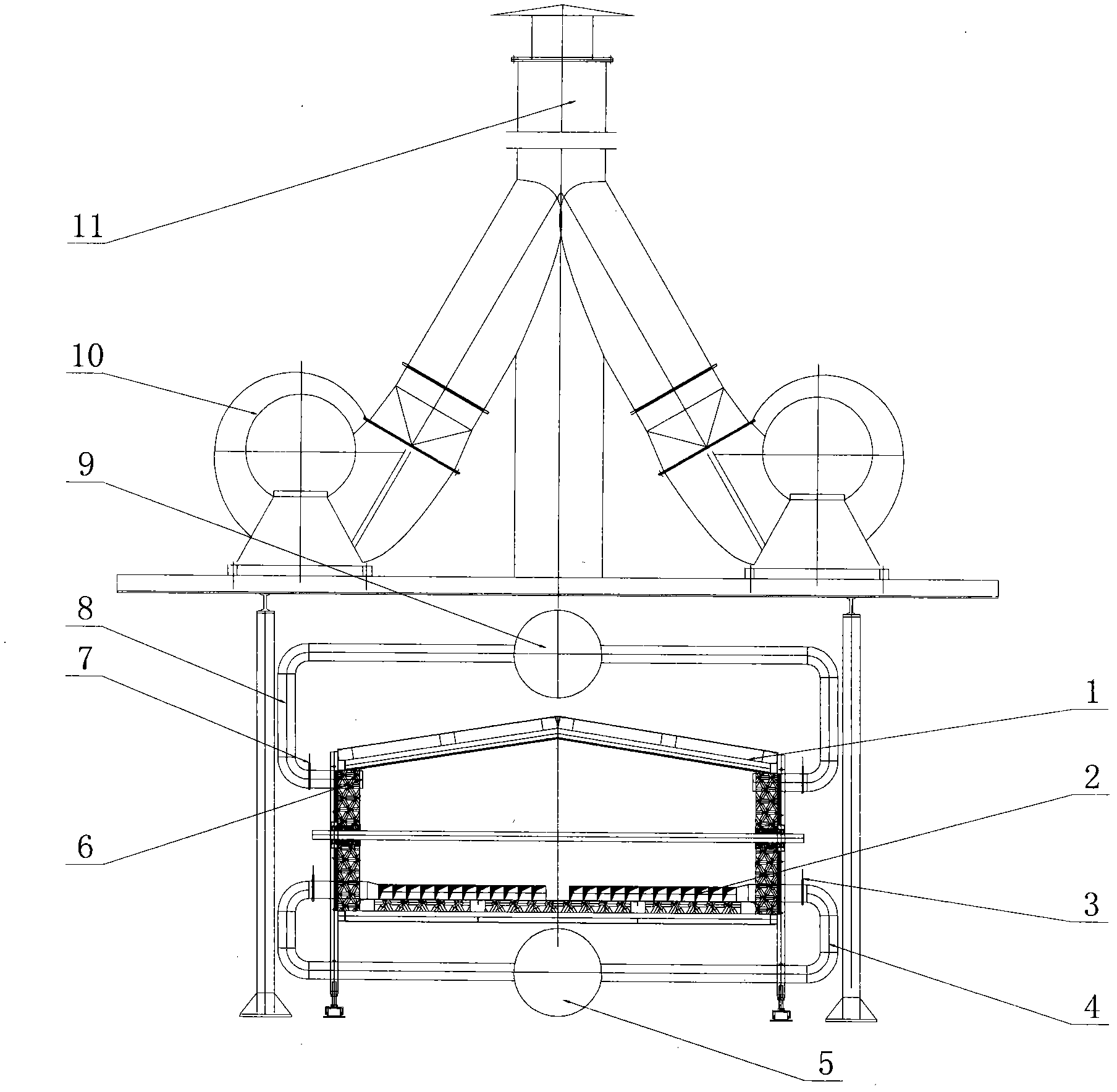

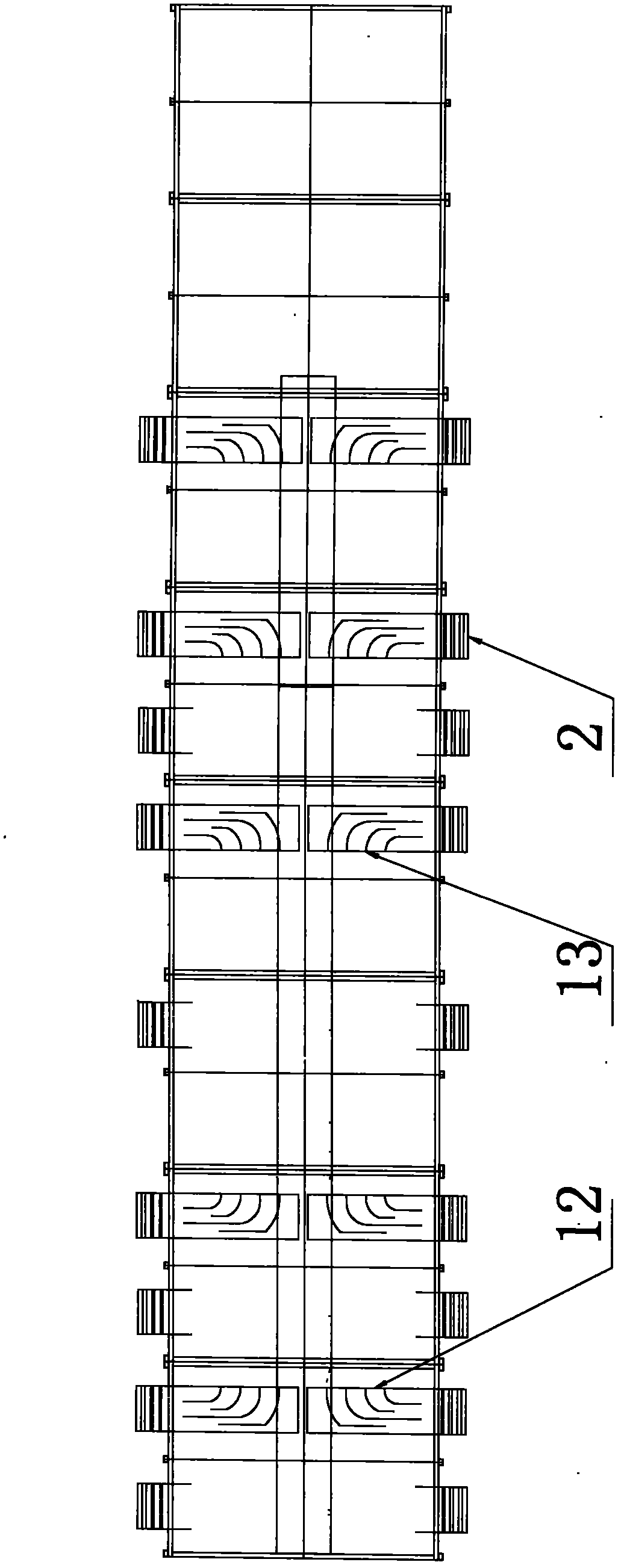

[0016] Attached below figure 1 to attach Figure 4 To further illustrate the present invention, the preferred embodiment of the present invention is: the drying channel for the roller kiln of exterior wall brick described in this embodiment, the described drying channel 1 is one layer, and the bottom of the drying channel 1 is provided with There are multiple air distributors 2 and 6, which are evenly distributed at the bottom of the channel symmetrically. Drive horizontally forward. The installed air distributor 2 communicates with the heating main pipe 5 through the communication pipe 4, and the heating main pipe 5 is installed on the outside of the bottom of the drying passage 1, and the air distribution valve 3 is arranged between the communicated air distributor 2 and the communication pipe 4. The side wall of the drying channel 1 located above the roller is provided with a moisture discharge port 6, and the moisture discharge port 6 is connected to the dehumidification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com