Method for producing a 2D collimator element and 2D collimator element

A collimator and component technology, applied in the direction of using aperture/collimator, instruments, scientific instruments, etc., can solve the problems of reducing the collimation effect of spacers, and achieve the goal of simplifying expenses, reducing cost expenses, and reducing component weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

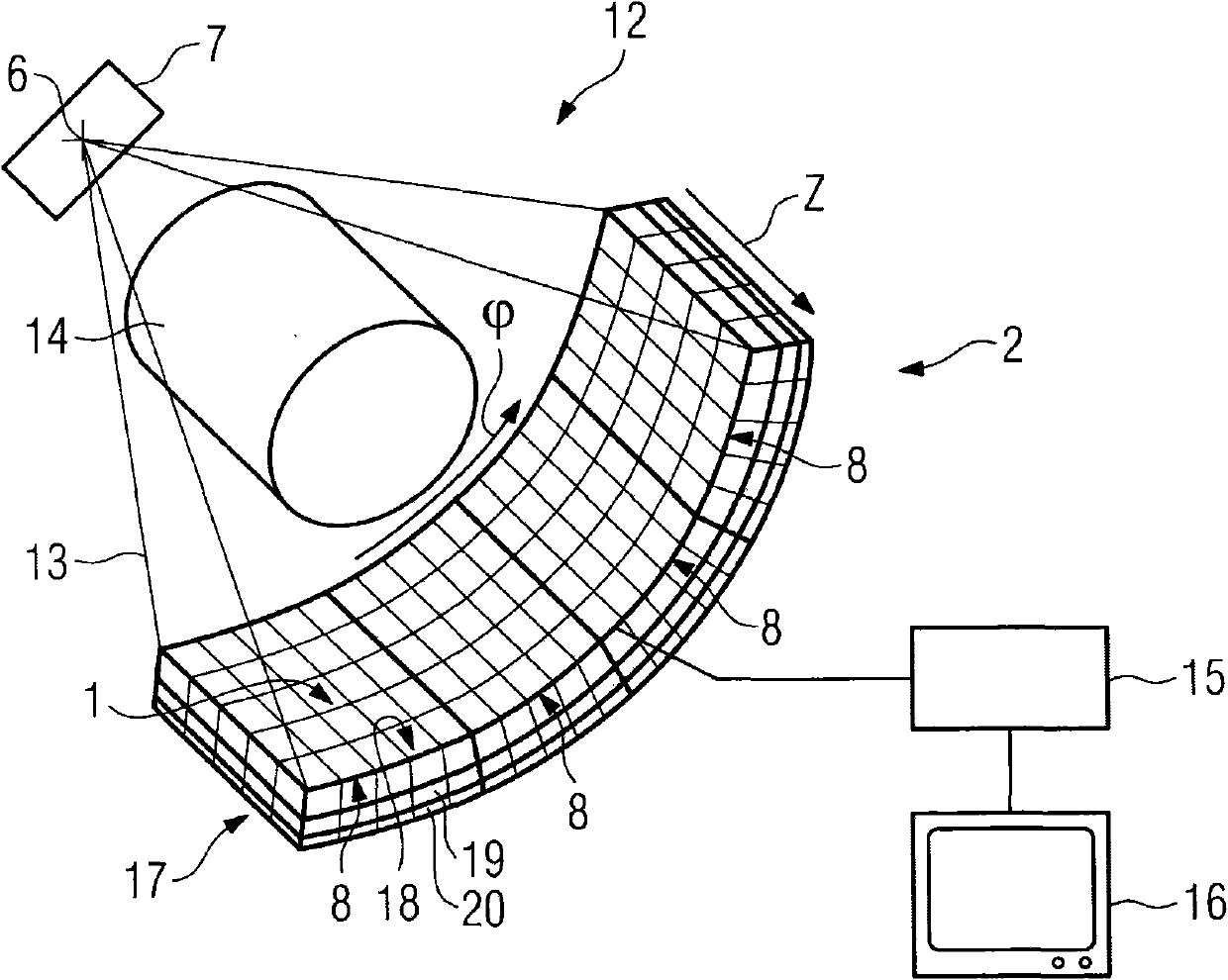

[0031] figure 1 A computed tomography system 12 is shown, which comprises a radiation source in the form of an x-ray tube 7 , from whose focal point a fan-shaped x-ray 13 is emitted. The fan-shaped x-rays 13 penetrate the object 14 to be examined or the patient and emerge at a radiation detector, here the x-ray detector 2 .

[0032] The x-ray tube 7 and the x-ray detector 2 are arranged opposite each other on a gantry of a computed tomography system 12 (not shown here), which surrounds the system axis z (=patient axis) of the computed tomography system 2 )exist direction is rotatable. which is, The direction indicates the circumferential direction of the gantry and the z-axis indicates the longitudinal axis of the object 14 to be examined.

[0033] During operation of the computed tomography system 2 , the x-ray tube 7 and the x-ray detector 2 arranged on a gantry rotate around the object 14 , wherein x-ray images of the object 14 are acquired from different projection d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com