Method for processing of pozzolans

A pozzolanic, process-period technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem that the performance of fly ash cannot be improved, the fluctuation of fly ash performance cannot be avoided, and the final product quality is constant. problems, to achieve the effect of reducing emissions and energy consumption, and increasing the amount of substitution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

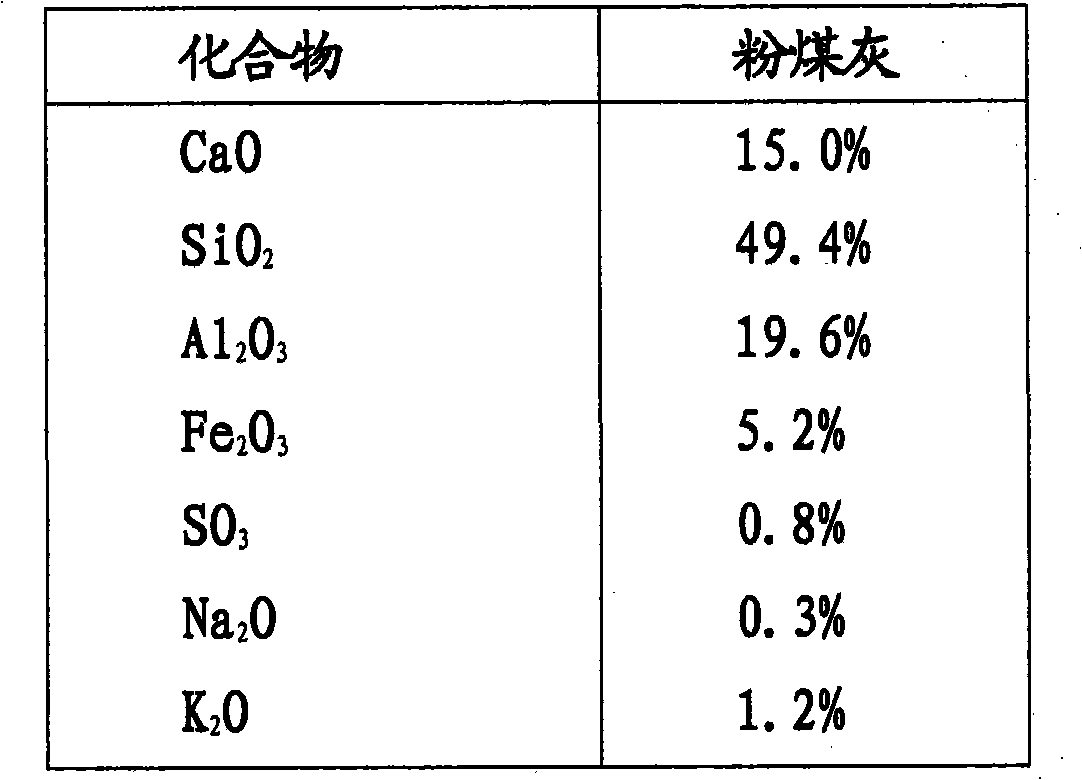

[0026] According to the present invention, F fly ash according to ASTM C with the chemical composition and particle size distribution (PSD) shown in Table 1 and Table 2 was tested.

[0027] Table 1. Chemical composition

[0028]

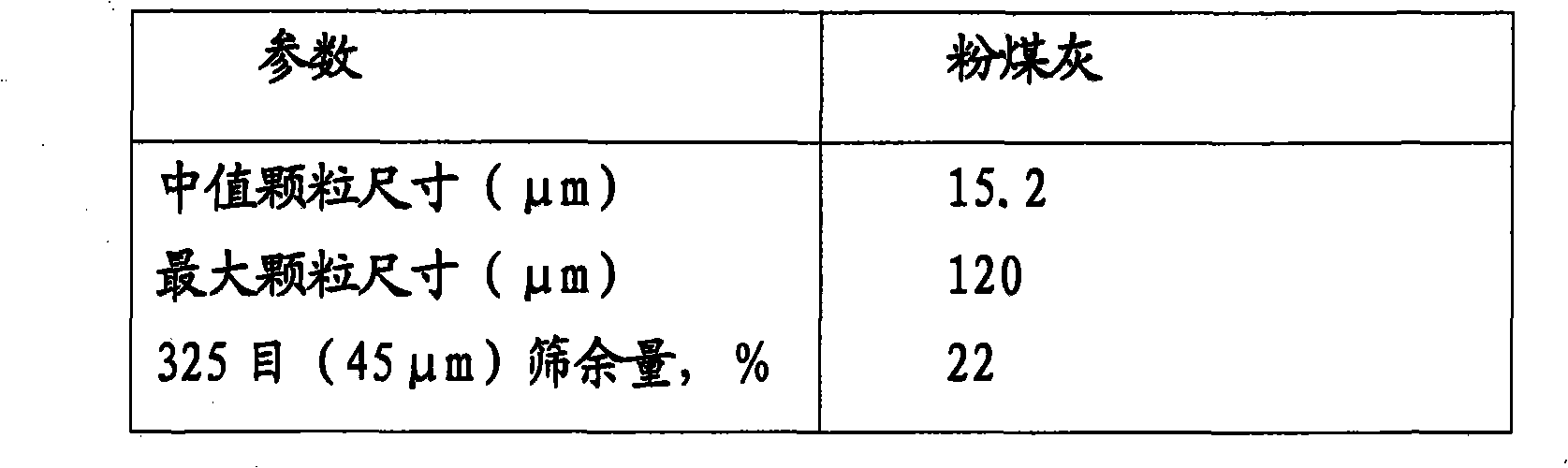

[0029] Table 2. Particle size distribution

[0030]

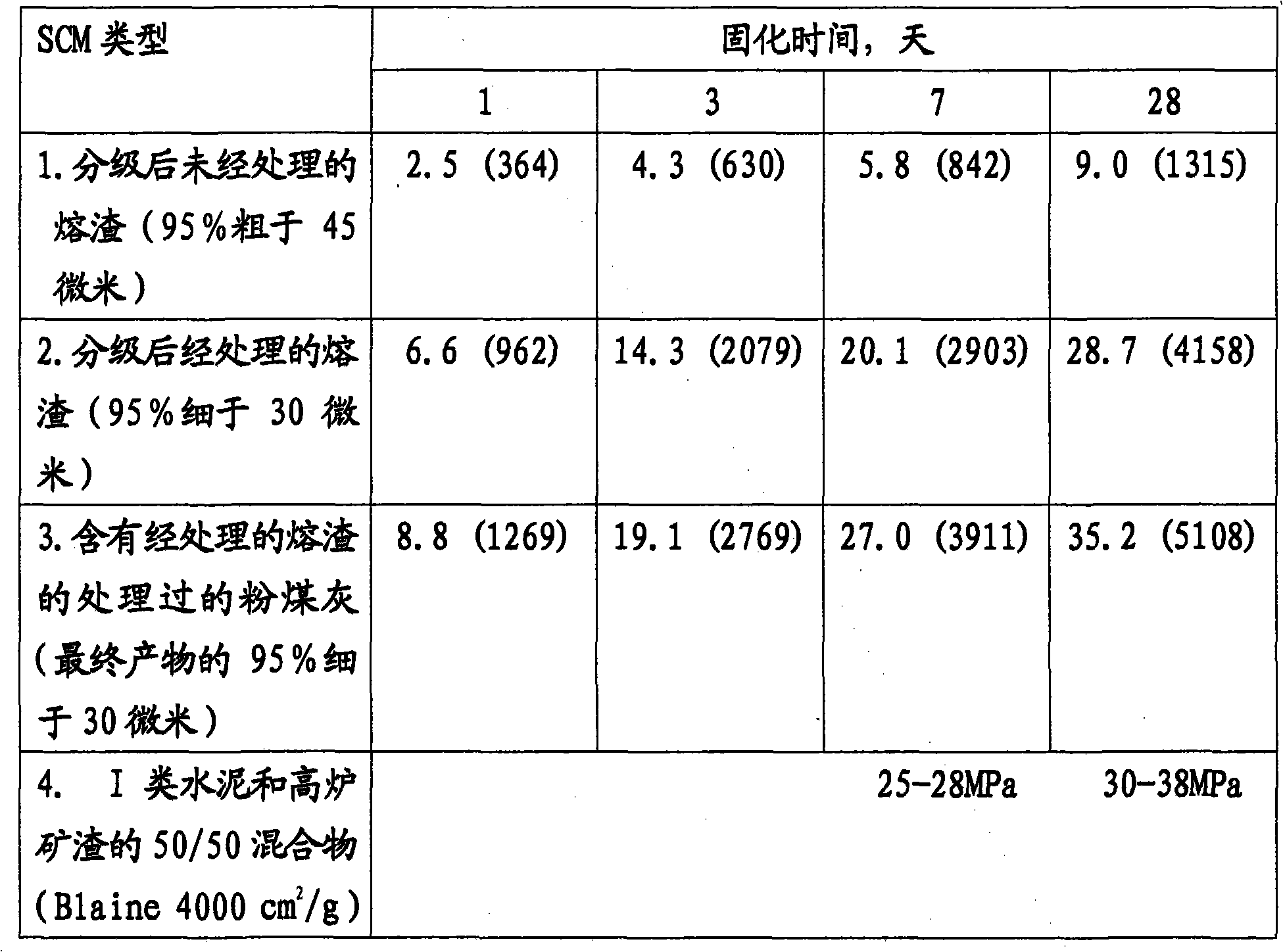

[0031] Table 3 below shows a 50 / 50 blend by weight of Portland cement (type 1 according to ASIM C 150) and untreated and treated auxiliary adhesive material (SCM) according to the invention according to ASTM C 109 The intensity of development.

[0032] Table 3. Compressive strength development, MPa(psi)

[0033]

[0034] The obtained test results show that the present invention converts the completely inert coarse-grained part with zero pozzolanic activity in the fly ash into an active part that has a significant contribution to the strength. The blended cement containing 50% Portland cement and 50% fly ash treated in accordance with the present invention exhibits a 50 / 50 blend of Class I cement and blast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com