Design method for fast reactor mixed uranium plutonium fuel component control

A technology of fuel composition and design method, applied in the directions of reactor fuel elements, reactor fuel materials, computer-aided design, etc., can solve the problems of component power change, affecting the temperature distribution of the outlet coolant, and large impact, and achieve the effect of reducing the impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

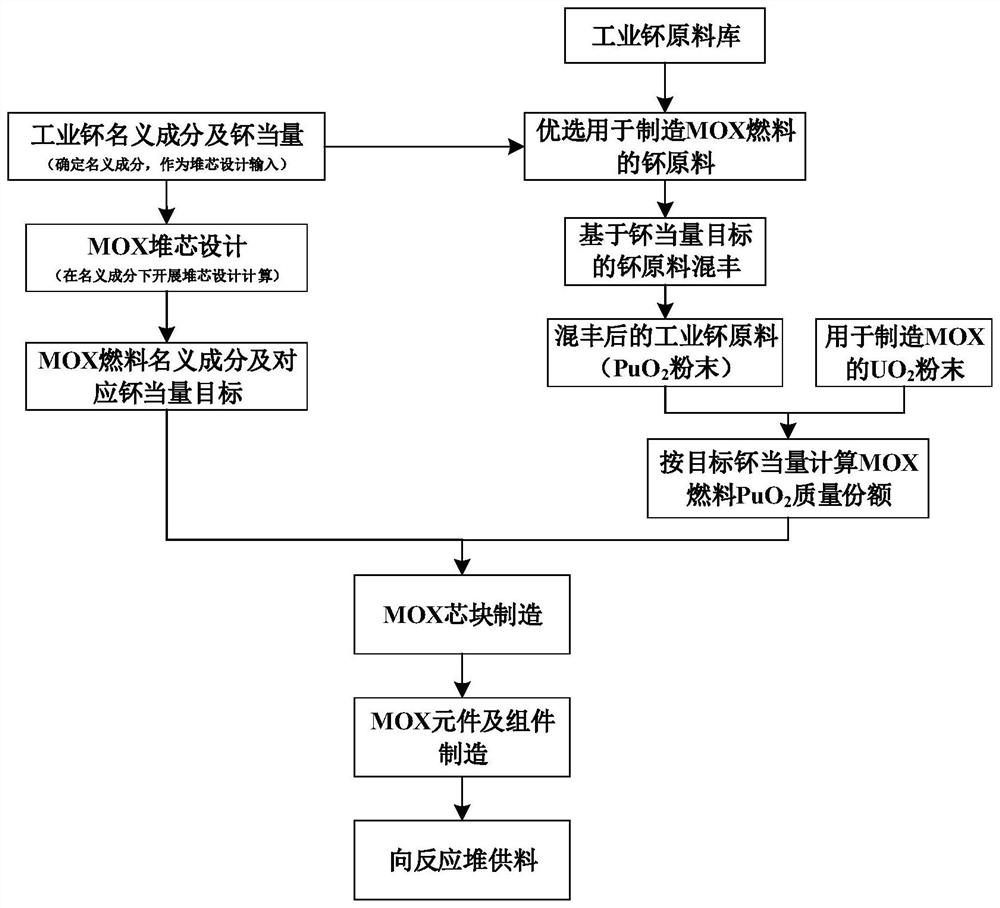

[0054] In the present embodiment, the method of the present invention is specifically described by taking mixed uranium plutonium oxide fuel (MOX) as an example, as figure 1 , figure 2 As shown, the method includes the following steps:

[0055] (1) Core design calculation, specifically including the following steps:

[0056] A. Determine the PuO used in the core material 2 The nominal composition of the powder, namely PuO 2 The types of industrial plutonium isotopes of powder and the mass percentages of each industrial plutonium isotope are used as the core design input, and the plutonium equivalent weight factors of each industrial plutonium isotope are calculated; according to the mass percentage of each industrial plutonium isotope and its plutonium equivalent weight factor, the Get PuO 2 The plutonium equivalent design value of the powder;

[0057] In mixed uranium-plutonium fueled fast reactors, 239 Pu is the main fissile nuclide and can be used 239 Pu is used as ...

Embodiment 2

[0085] Fuel Design Calculation for the First Fuel of a MOX Fueled Fast Reactor

[0086] Taking a 600,000-kilowatt sodium-cooled MOX fuel fast reactor as an example, the reactor core is designed with a rated thermal power of 1,500 MW. The reactor uses MOX fuel, in which industrial plutonium comes from the reprocessing of spent fuel from pressurized water reactors, and depleted uranium is used for uranium. The coolant uses liquid metal sodium. The balanced state core is loaded with 348 boxes of MOX fuel assemblies, which are divided into inner, middle and outer regions according to different enrichment degrees. Since the industrial plutonium in the MOX fuel is planned to come from the industrial plutonium in the spent fuel of the PWR recovered by the reprocessing plant, the balanced core design is carried out based on the nominal plutonium composition given by the reprocessing plant, and the plutonium in the MOX fuel in each zone is determined The uranium composition ratio, wh...

Embodiment 3

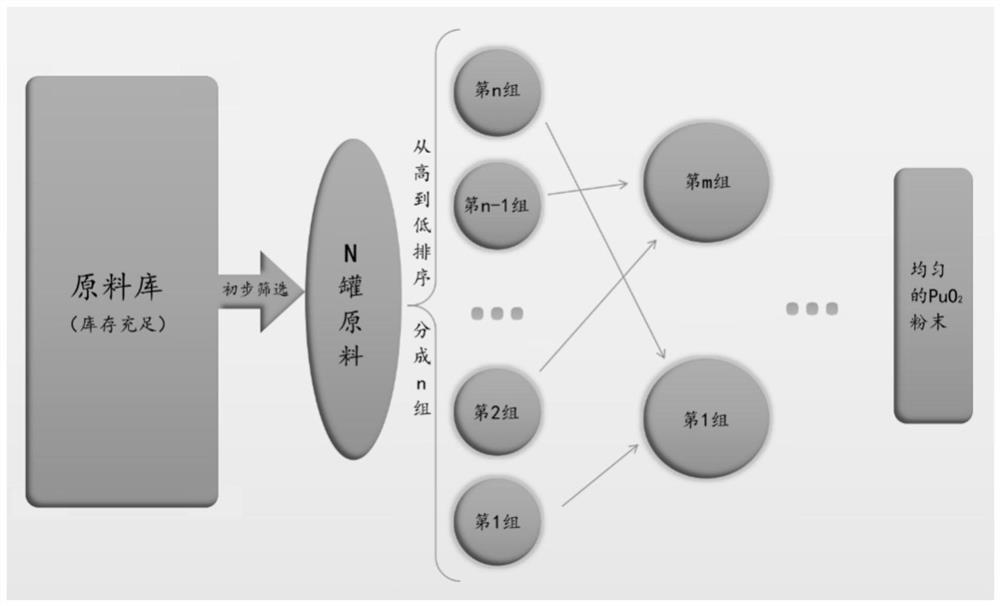

[0098] A million-kilowatt class sodium-cooled MOX fuel core is selected as an example. In order to flatten the power distribution of the core, the fuel assemblies are divided into inner, middle and outer zones according to the degree of enrichment, and the number of fuel assemblies loaded in the three zones are 211, 156 and 174 respectively. The core control rod system consists of 30 control rods, including 2 adjustment rods, 3 passive safety rods, 9 safety rods and 16 compensation rods. When designing the core, consider PuO 2 The plutonium isotopic composition of the powder is a definite value (namely the nominal value), and the adjustment of the enrichment of the fuel in the inner, middle and outer regions is by changing the PuO 2 Powder and Depleted UO 2 The proportion of powder to achieve. The design value of the industrial plutonium isotopic composition of the core fuel of the first furnace is shown in Table 4, and this fuel composition is the target composition of mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com