Apparatus integrating surface vacuum spraying of workpiece, paint solidifying and waste paint and solvent recycling, and process thereof

A paint curing and workpiece surface technology, applied in the device for coating liquid on the surface, pretreatment surface, coating and other directions, can solve the problems of high technical requirements, environmental pollution, harsh working environment, etc., to achieve smooth and uniform sprayed surface, The effect of reducing production cost and enhancing atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Example: Vacuum spraying, paint curing, waste paint and solvent recovery integrated equipment and process on the surface of helmet workpiece

[0035] 1. Integrated equipment for vacuum spraying, paint curing, waste paint and solvent recovery on the surface of the workpiece

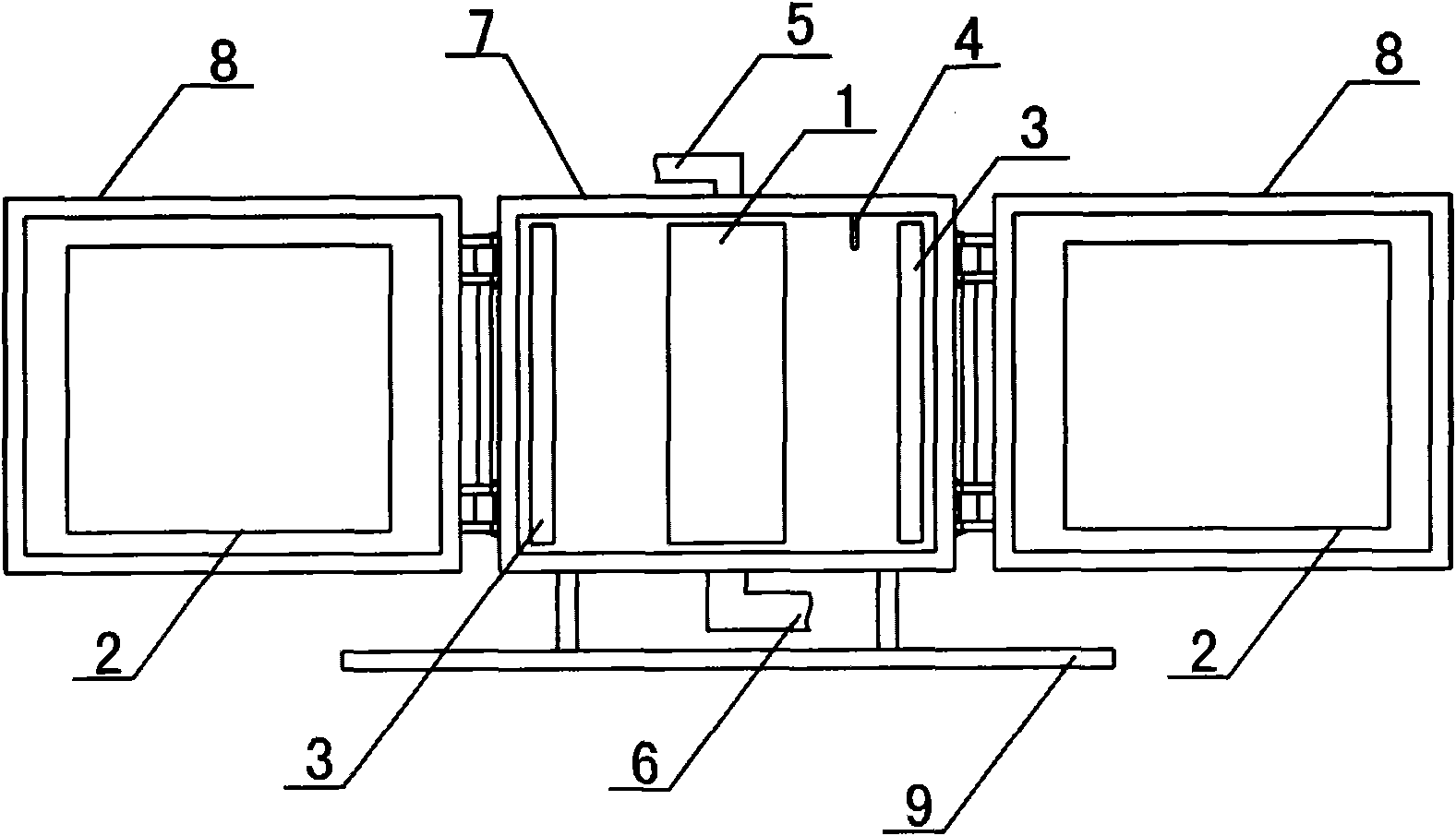

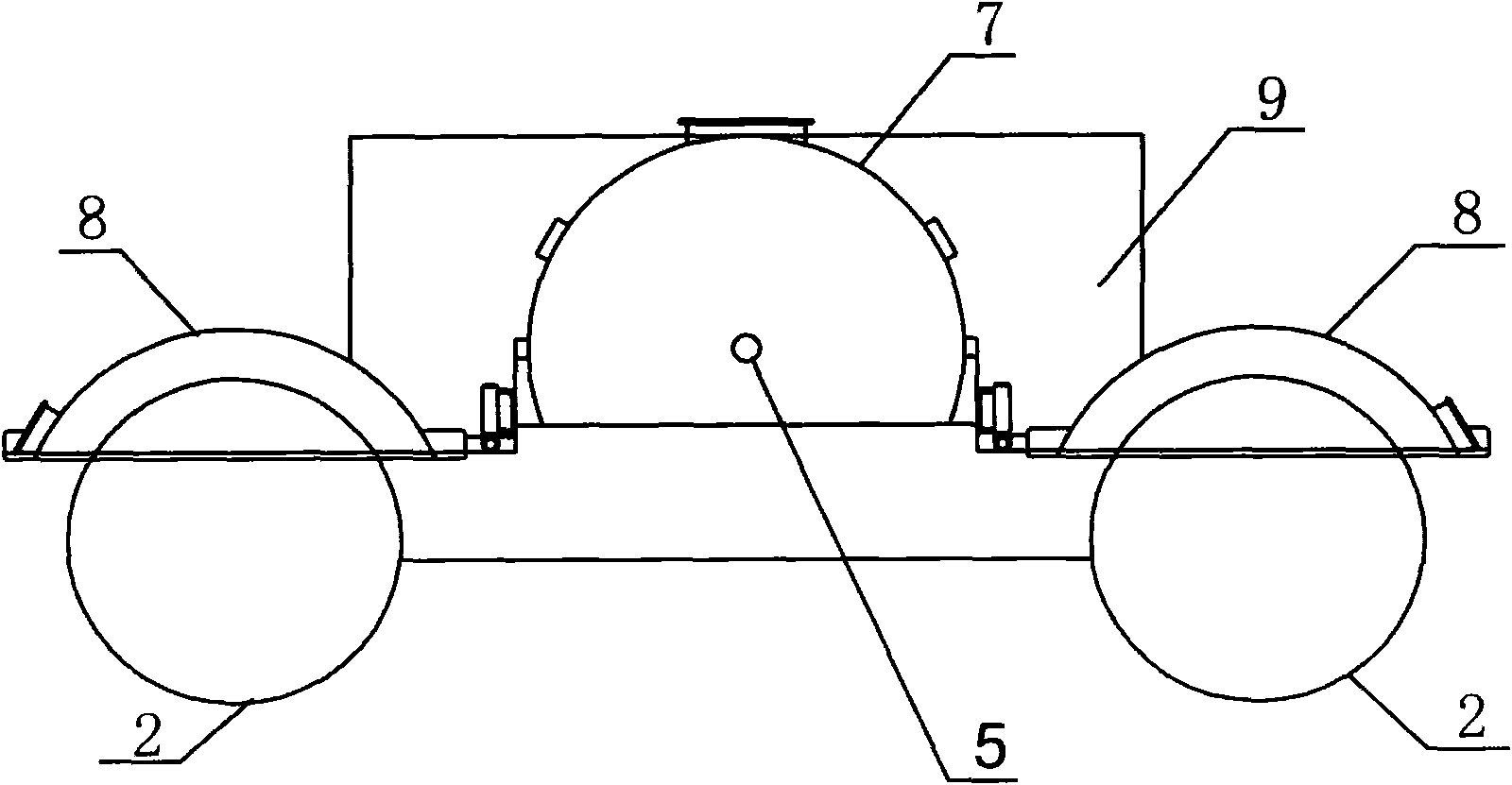

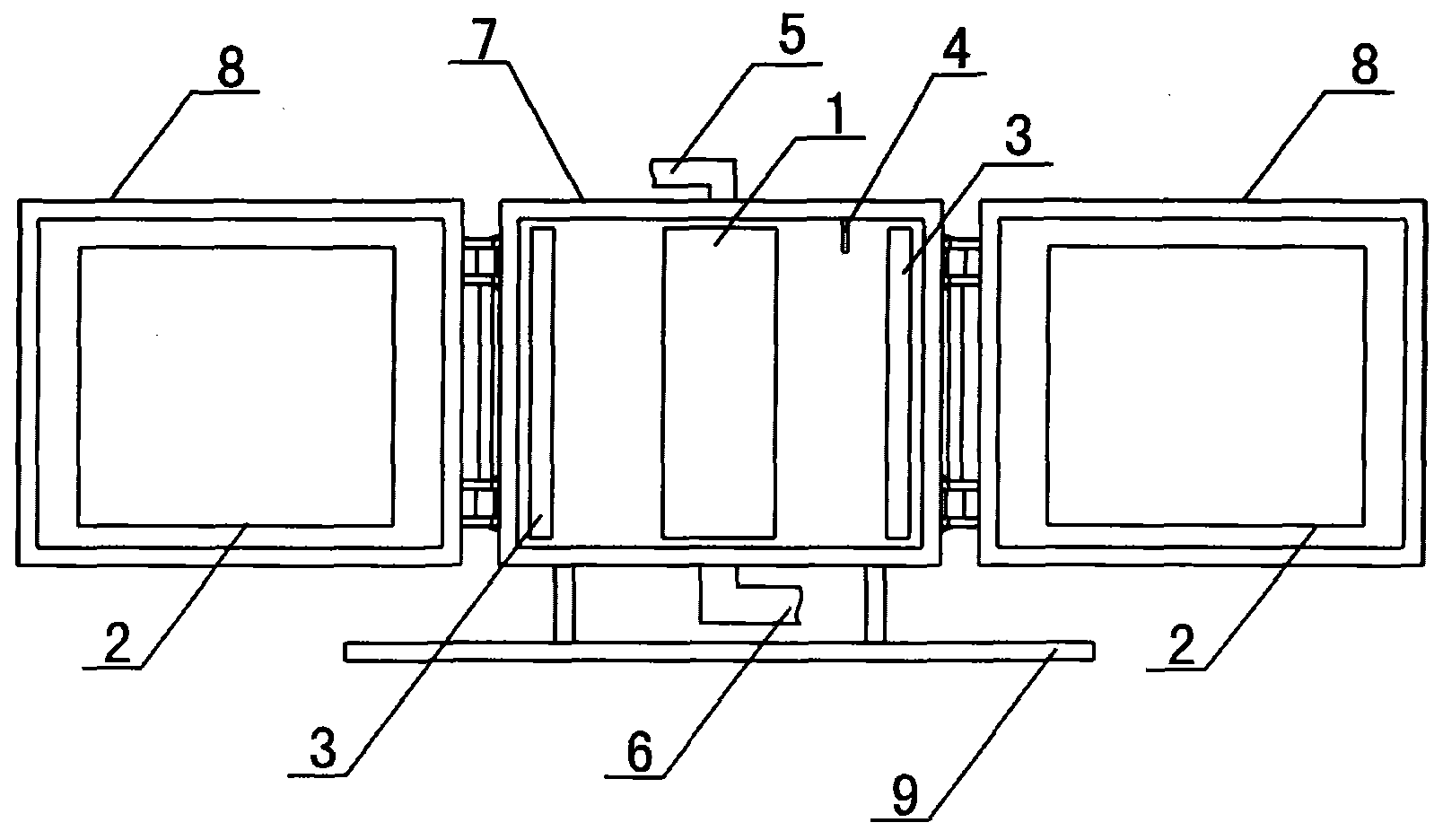

[0036] like figure 1 , figure 2 Shown:

[0037] 1. Integrated vacuum chamber for painting and paint curing

[0038] The integrated vacuum chamber for spraying paint and paint curing is a cylindrical metal container, and one side of the cylindrical metal container is provided with an airtight door that can be turned and opened or closed. The empty chamber is equipped with a spray gun, a workpiece hanger turntable, a heating device, a temperature detection device, an air inlet pipe and an air exhaust pipe.

[0039] The spray gun is arranged on one side of the vacuum chamber, the spray gun is an automatic air spray gun, and the number is 4. The surface of the helmet that requires surface vacuum s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com