Steel wire cutter of steel wire ring

A technology of steel traveler and steel wire, which is applied to tires, manufacturing rings by wire, and other household appliances, etc., can solve the problems of time-consuming, labor-intensive, cost-increasing, and low utilization of equipment, so as to reduce costs, reduce workload, and shorten production cycles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

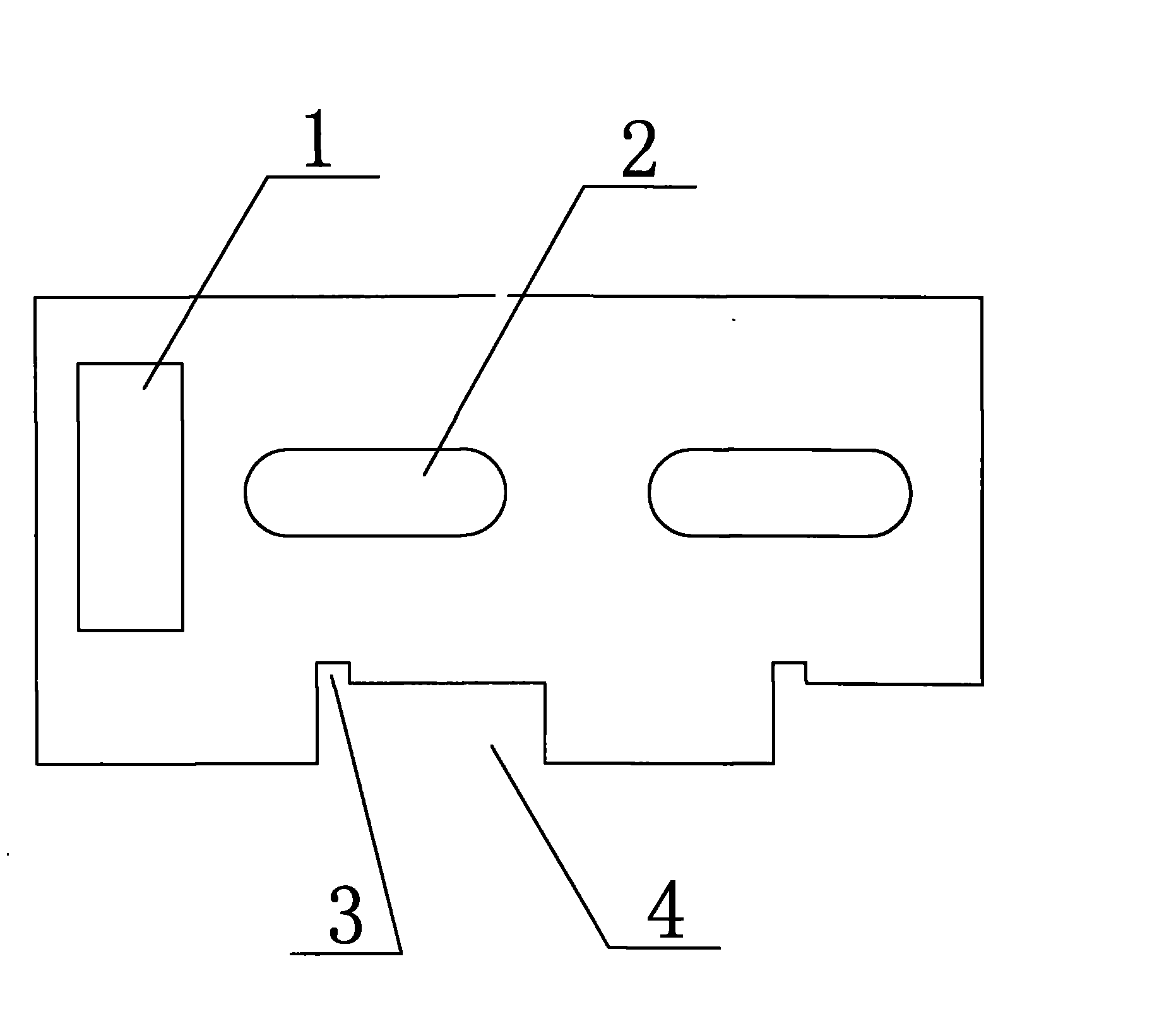

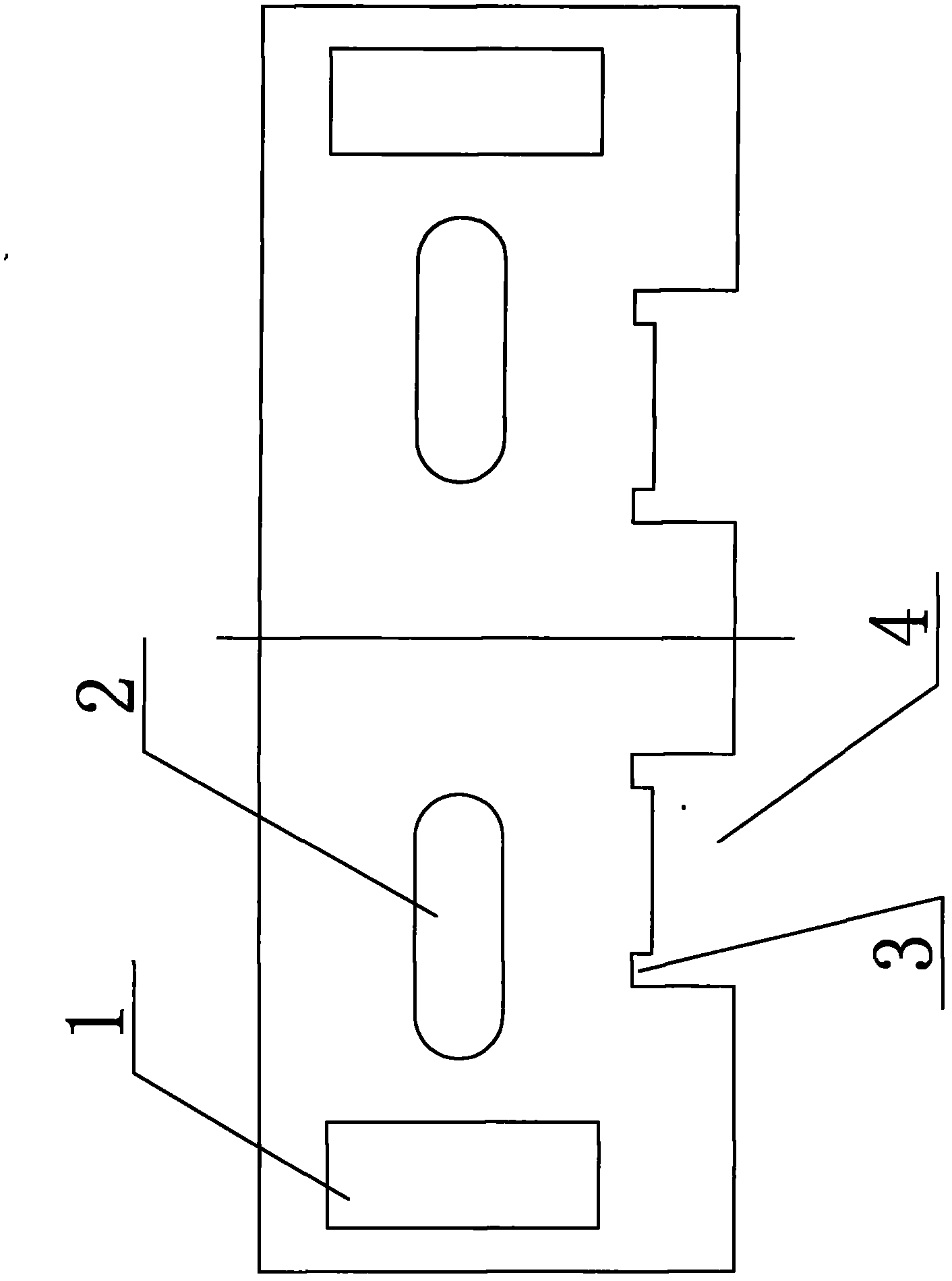

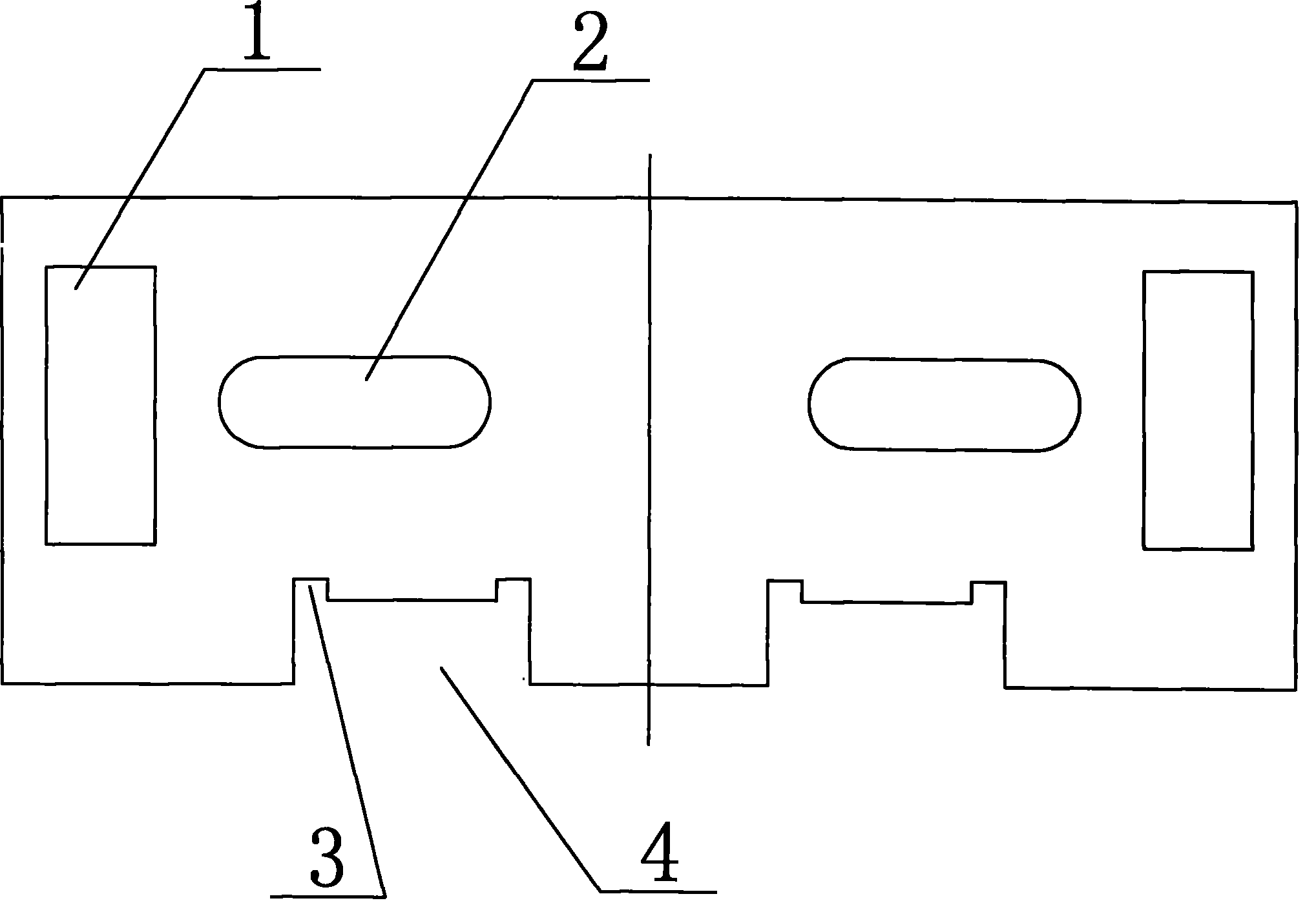

[0014] like figure 2 As shown, the traveler steel wire cutting knife of the present invention is composed of a knife holder and an alloy cutter head. Two waist circular positioning holes 2 and two square connections for connecting with the hook on the central axis of the hydraulic cylinder are provided on the knife holder. Holes 1 and two gaps 4 inlaid with alloy cutter heads, each bottom end of the gap 4 is respectively provided with two insert grooves 3, the positioning hole 2, the connecting hole 1 and the gap 4 are defined by the long side of the upper surface of the tool holder. The center line of the blade is arranged symmetrically on the left and right, and the alloy cutter head matched with the blade holder has double-sided blades.

[0015] The distance between the two insert grooves 3 in the above-mentioned notch 4 is 25-40 mm, preferably 30 mm.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap