Household garbage vertical burning rotary grate furnace system

A technology for rotating grate and household garbage, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as large workload, large equipment investment, and inability to burn through, so as to ensure decomposition, improve work efficiency, and improve air quality. effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The purpose, features and advantages of the present invention will be further described with reference to the accompanying drawings in conjunction with the embodiments. Examples will help to understand the present invention, but do not limit the content of the present invention. All deformations that can be directly derived or associated by those skilled in the art from the content disclosed in the present invention should be considered as the protection scope of the present invention.

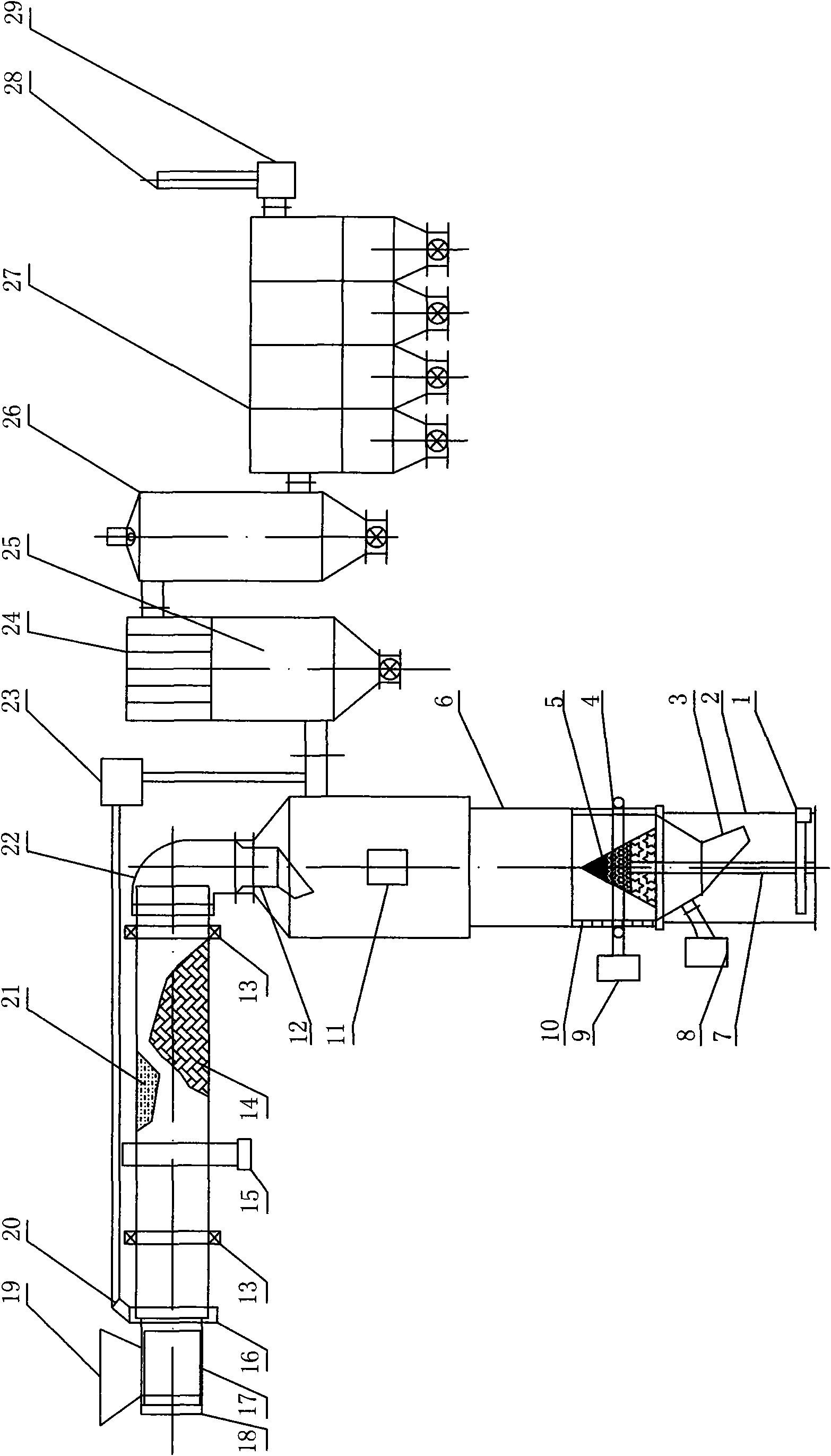

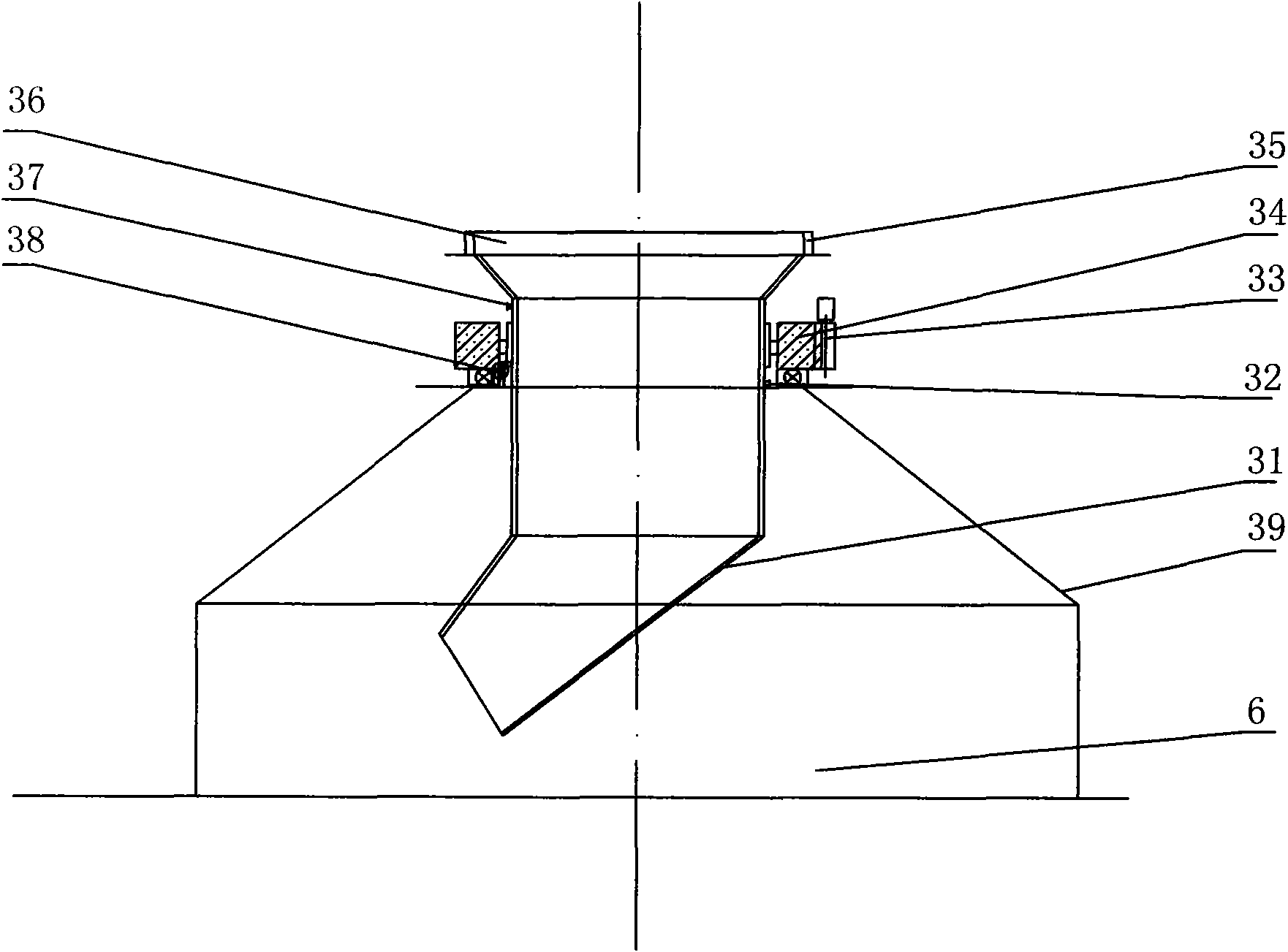

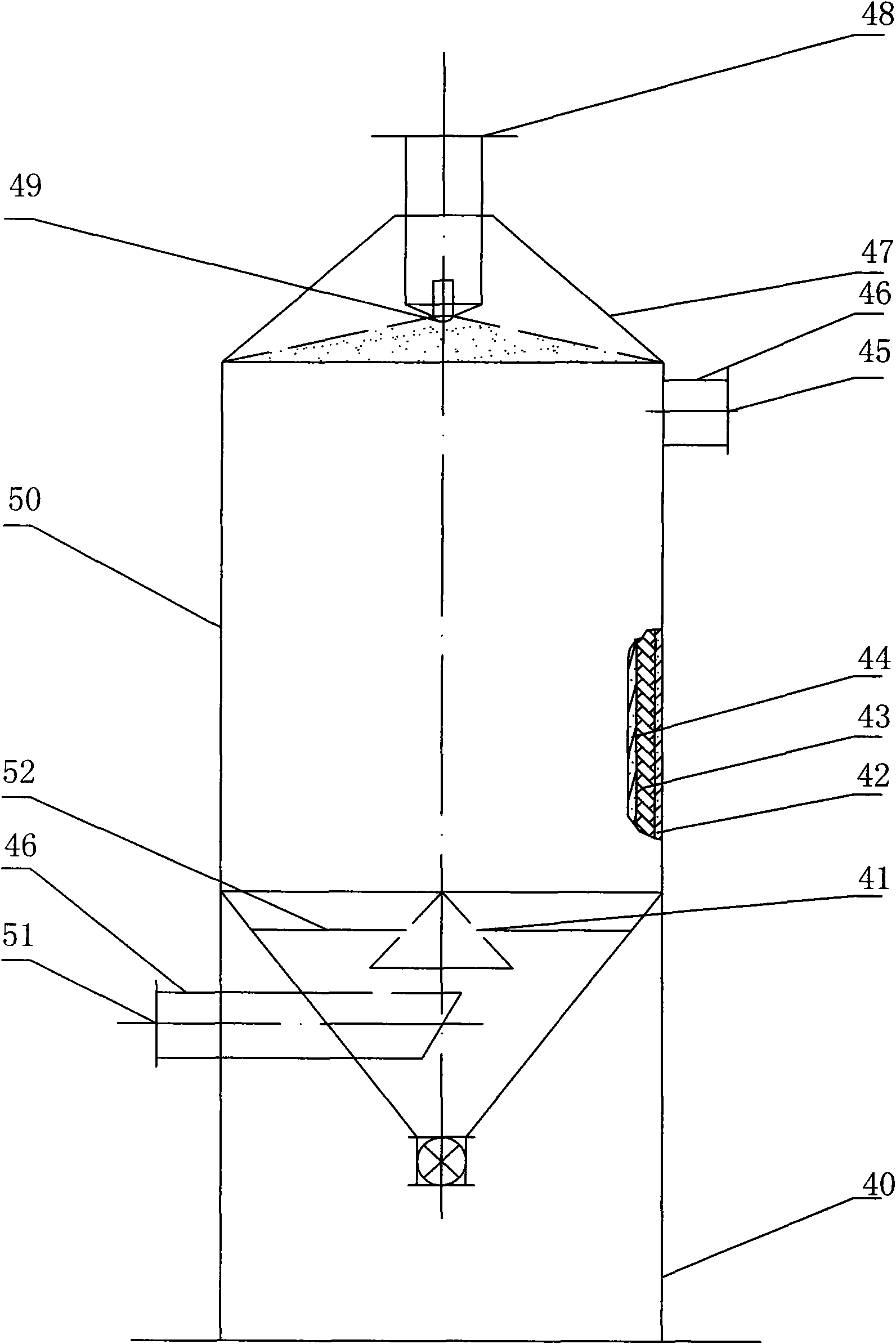

[0026] A rotary grate furnace system for vertical incineration of domestic waste, which includes a discharge transmission device 1, a bracket 2, a slag discharge pipe 3, an annular air pipe 4, a multi-layer tower grate 5, an incinerator main body 6, a transmission column 7, an inlet Fan 8, Roche blower 9, rotating material distribution device 12, garbage feeding dryer 30, cam device 13, feeding transmission device 15, flue gas connection cover 16, feeding outer cylinder 17, feeder 18, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com